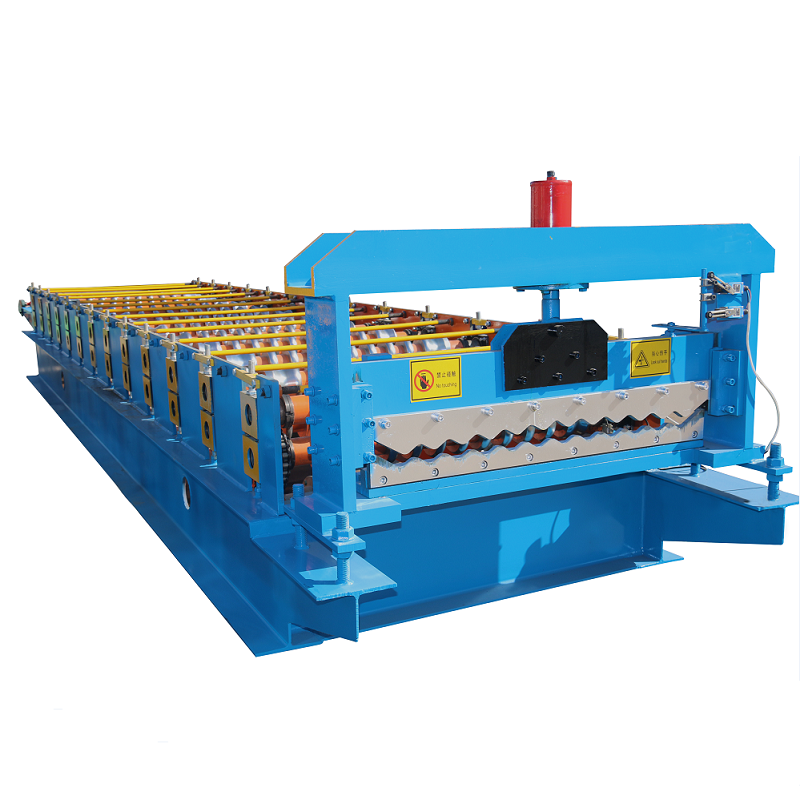

High-Quality Corrugated Sheet Roll Forming Machine for Sale - Buy Now!

By:Admin

The Corrugated Sheet Roll Forming Machine is designed to produce high-quality corrugated sheets at a rapid pace. With its advanced technology and precision engineering, this machine is capable of creating uniform and accurate corrugations in the metal sheets, ensuring a consistent and reliable end product. This will be a game-changer for companies in the roofing, construction, and packaging industries, as it will significantly enhance their production capabilities.

One of the key features of the Corrugated Sheet Roll Forming Machine is its versatility. It is capable of producing a wide range of corrugated sheet profiles, allowing manufacturers to meet the diverse needs of their customers. Whether it's for roofing materials, siding panels, or custom packaging solutions, this machine can handle it all with ease. This flexibility will give businesses a competitive edge in the market, as they can cater to a variety of industries and applications.

In addition to its impressive performance, the Corrugated Sheet Roll Forming Machine is also easy to operate and maintain. It is equipped with user-friendly controls and intuitive software, making it simple for operators to set up and run the machine with minimal training. Furthermore, the machine is built to withstand the rigors of continuous use, ensuring long-term reliability and durability for the end user.

{Company Name} takes pride in the quality and reliability of their machinery, and the Corrugated Sheet Roll Forming Machine is no exception. Each machine is meticulously engineered and manufactured to the highest standards, using only the finest materials and components. This commitment to excellence ensures that customers can rely on their {Company Name} machine to deliver consistent performance and exceptional results for years to come.

The introduction of the Corrugated Sheet Roll Forming Machine is a testament to {Company Name}'s ongoing dedication to innovation and continuous improvement. By staying at the forefront of technology and design, they are able to provide their customers with cutting-edge solutions that meet the evolving demands of the industry. With this new machine, {Company Name} is poised to set a new benchmark for corrugated sheet production, offering unmatched quality, efficiency, and versatility.

As a leading manufacturer in the roll forming industry, {Company Name} has earned a reputation for delivering top-of-the-line machinery and unparalleled customer service. With the introduction of the Corrugated Sheet Roll Forming Machine, they are once again demonstrating their commitment to empowering manufacturers with the tools they need to succeed. This new machine is sure to make a significant impact in the market, and {Company Name} is excited to see the positive outcomes it will bring to their customers.

In conclusion, the Corrugated Sheet Roll Forming Machine is set to redefine how corrugated sheets are produced. Its advanced technology, versatility, and reliability make it a valuable asset for manufacturers across various industries. Coupled with {Company Name}'s reputation for excellence, this new machine is poised to elevate the standard for corrugated sheet production and solidify {Company Name} as a leader in the roll forming industry.

Company News & Blog

Efficient Cut-To-Length Machine Revolutionizes Fabric Industry

Title: Cutting-edge Fabric Cut-to-Length Machine Revolutionizes Textile IndustryIntroduction:The fabric cut-to-length machine, a groundbreaking innovation in the textile industry, is set to transform the way fabrics are processed and cut. Developed by a leading company in textile machinery (), this cutting-edge technology promises to enhance efficiency, precision, and productivity in fabric manufacturing while reducing waste and operational costs. By focusing on revolutionary design and incorporating advanced features, this machine is poised to revolutionize fabric cutting processes globally.Paragraph 1:Manufacturers in the textile industry have long been facing challenges relating to efficient and accurate fabric cutting. Traditional cutting methods often result in time-consuming, labor-intensive processes that lead to inconsistencies and inaccuracies. The introduction of the fabric cut-to-length machine aims to overcome these hindrances and provide an automated solution that streamlines the entire cutting process.Paragraph 2:The fabric cut-to-length machine utilizes state-of-the-art technology to deliver high precision cutting, reducing material waste and optimizing fabric utilization. With programmable settings and a user-friendly interface, the machine enables manufacturers to achieve precise dimensions consistently. This innovation not only saves time but also eliminates errors, ensuring uniformity throughout the production process.Paragraph 3:One of the key features of this machine is its ability to accommodate a wide variety of fabric types. Whether it is delicate silk, robust denim, or intricate lace, the machine's advanced cutting mechanisms deliver clean, accurate cuts without compromising the integrity of the fabric. Such versatility enables fabric manufacturers to expand their product lines and cater to diverse customer needs, significantly enhancing their competitiveness in the market.Paragraph 4:In addition to its cutting precision, the fabric cut-to-length machine incorporates efficiency-enhancing mechanisms, such as conveyor systems and automated fabric feeders. These features enable continuous processing and seamless integration with other textile machinery, minimizing downtime and maximizing productivity. Furthermore, its intuitive control panel allows operators to monitor and adjust settings easily, fostering a smoother workflow.Paragraph 5:Environmental sustainability is a growing concern in the textile industry. The fabric cut-to-length machine tackles this issue through material optimization, reducing fabric wastage significantly. By eliminating manual errors and ensuring efficient use of fabric, the machine helps manufacturers reduce their carbon footprint and minimize the environmental impact of fabric production.Paragraph 6:The impact of the fabric cut-to-length machine extends beyond the manufacturing floor, as it also positively influences the bottom line. By reducing fabric waste and increasing productivity, manufacturers can experience significant cost savings over time. Additionally, the machine's longevity and durability contribute to its cost-effectiveness, making it a valuable investment for textile companies seeking to optimize their operations in the long run.Paragraph 7:The introduction of this innovative fabric cut-to-length machine marks a new era in the textile industry, establishing new standards of quality, efficiency, and sustainability. Through its intelligent design, versatility, and ability to streamline fabric cutting processes, manufacturers are now empowered to meet the growing demands of customers while staying competitive in a rapidly evolving market.Conclusion:The fabric cut-to-length machine developed by () is poised to revolutionize the textile industry, simplifying and automating the fabric cutting process. With its precision, versatility, and cost-effectiveness, this cutting-edge technology has the potential to reshape the fabric manufacturing landscape, enabling manufacturers to optimize their operations and meet the ever-growing demands of the market. As the textile industry continues to evolve, the fabric cut-to-length machine will empower companies to embrace change, improve efficiency, and remain at the forefront of innovation.

New Roll Forming Machine That Manufactures Metal Studs in Record Time

Title: Innovative Metal Stud Roll Former Revolutionizes the Construction IndustryIntroduction:In today's construction industry, ensuring efficiency, precision, and cost-effectiveness is crucial for companies to succeed. A dynamic player in this industry, Company XYZ, has introduced a groundbreaking innovation: the Metal Stud Roll Former. This advanced technology has the potential to revolutionize the way metal studs are manufactured, making construction processes faster, more accurate, and more customizable. With its exceptional features and capabilities, the Metal Stud Roll Former is set to become an indispensable tool for construction companies worldwide.Expanding Manufacturing Capabilities:Company XYZ's Metal Stud Roll Former is a state-of-the-art machine that combines cutting-edge technology with advanced engineering. This compact device is capable of producing the highest quality metal studs with remarkable efficiency. By offering various sizes and shapes, the Roll Former allows construction companies to customize their metal studs according to specific project requirements. This level of flexibility is unparalleled in the industry and provides construction professionals with a powerful tool to enhance their productivity and creativity.Enhanced Precision and Durability:With its precision-machined components and innovative automation, the Metal Stud Roll Former ensures consistent and accurate results. The machine's computerized controls and sensors guarantee precise measurements and uniform shapes, eliminating the risk of errors and wastage. Additionally, this advanced technology significantly reduces human labor, leading to decreased costs and improved profitability for construction companies. Moreover, the use of high-quality materials in the roll forming process enhances durability, ensuring long-lasting and reliable metal studs that can withstand even the harshest of construction environments.Streamlined Workflow:The Metal Stud Roll Former offers a streamlined production process that is unrivaled in the industry. Its automated features reduce manual intervention, minimizing the chances of human error and optimizing manufacturing efficiency. The machine seamlessly integrates into existing production lines, saving valuable time and resources. Additionally, the Roll Former's intuitive interface and user-friendly controls enable easy operation, even for less experienced workers. This intuitive workflow increases productivity, allowing construction companies to meet project deadlines efficiently and effectively.Sustainable and Green Manufacturing:In today's environmentally-conscious world, sustainability is a vital aspect of any industry. The Metal Stud Roll Former aligns with this requirement by offering sustainable features. The roll forming process itself produces minimal waste, and any leftover materials can be easily recycled. The energy-efficient design of the machine reduces power consumption, contributing to a greener manufacturing process. By utilizing the Metal Stud Roll Former, construction companies can demonstrate their commitment to sustainability while reducing waste and consumption.Elevating Industry Standards:The introduction of the Metal Stud Roll Former sets a new benchmark for the construction industry, elevating the standards of manufacturing metal studs. This game-changing technology opens up new possibilities for architects, engineers, and contractors, enabling them to explore innovative designs and constructions. With its high-quality output, efficiency, and adaptive capabilities, the Roll Former empowers construction companies to push boundaries and deliver exceptional results for their clients. By embracing this cutting-edge technology, companies can differentiate themselves from the competition and gain a competitive advantage in the market.Conclusion:Company XYZ's Metal Stud Roll Former represents a significant breakthrough in the construction industry. Its advanced technological features provide unparalleled precision, durability, and efficiency, transforming the way metal studs are manufactured. By investing in this innovative technology, construction companies can improve productivity, reduce costs, and enhance their environmental sustainability. The Metal Stud Roll Former is poised to become an essential tool for the modern construction industry, fostering creativity, efficiency, and superior quality outputs.

High-Quality Metal Slitting Line for Sale: Buy Different Gauge Slitting Line Machines

In the manufacturing industry, slitting lines are crucial machines that are used to cut wide metal coils into narrower strips of specific widths. These narrower strips can then be used for various applications, such as the production of pipes, automotive parts, and household appliances.As one of the leading manufacturers of slitting lines, {Steel Slitting Line} is committed to delivering high-quality machines that are designed to meet the needs of their customers. Their slitting lines are available in light, medium, and heavy gauge options, making it easier for customers to find the right machine based on their specific requirements.One of the main advantages of using a slitting line from {Steel Slitting Line} is that it is designed to minimize material waste. This is accomplished by using a looping pit that allows for tighter control over the material feeding process. Additionally, {Steel Slitting Line} slitting lines are designed with precision in mind, which ensures that the strips produced are of consistent widths.Another key feature of {Steel Slitting Line} slitting lines is their ease of use. These machines are designed to be user-friendly, with simple controls that allow operators to quickly and easily adjust the machine settings. This makes it easier for manufacturers to produce high-quality metal strips in a timely and efficient manner.When it comes to choosing a slitting line, there are a few important factors to consider. One of the most important is the gauge of the material being processed. {Steel Slitting Line} offers slitting lines for light, medium, and heavy gauge materials, making it easier for manufacturers to find the right machine for their specific needs.Another important factor to consider is the speed of the slitting line. Depending on the size of the coils being processed and the required strip widths, different machines will operate at different speeds. {Steel Slitting Line} offers machines with varying speed options, allowing manufacturers to choose a machine that is best suited for their specific production needs.At the end of the day, choosing the right slitting line can be the difference between success and failure for many manufacturing businesses. With the high-quality machines from {Steel Slitting Line}, manufacturers can rest assured that they are investing in a reliable and efficient machine that will help them meet their production goals. So if you're in the market for a new slitting line, be sure to check out the offerings from {Steel Slitting Line}.

High Quality Roof Tin Making Machine for Sale - Find Out More Here!

Roof Tin Making Machine Revolutionizes the Manufacturing IndustryRoofing has long been an essential component of construction, and the demand for high-quality roofing materials continues to grow. In response to this increasing demand, (Company Name) unveils its latest innovation - a state-of-the-art Roof Tin Making Machine.With over 20 years of experience in the manufacturing industry, (Company Name) has established itself as a leading provider of machinery and equipment for the construction and building materials sector. The company's commitment to innovation and quality has made it a trusted partner for businesses around the world.The Roof Tin Making Machine is the latest addition to (Company Name)'s impressive portfolio of products. This cutting-edge machine is designed to streamline the production process for roofing materials, significantly increasing efficiency and reducing labor costs. By investing in this advanced technology, businesses can expect to see a significant improvement in their bottom line.The Roof Tin Making Machine is equipped with the latest features and functionalities to ensure precision and consistency in the production of roof tins. Its automated operation minimizes the risk of human error, resulting in high-quality end products that meet industry standards. Additionally, the machine is built to be durable and long-lasting, making it a valuable asset for any manufacturing facility.One of the most notable features of the Roof Tin Making Machine is its versatility. It is capable of producing a wide range of roof tin profiles, allowing businesses to cater to diverse customer needs without the need for multiple machines. This flexibility not only saves space but also reduces the initial investment required for setting up a production line.Furthermore, the Roof Tin Making Machine is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels. This ensures that businesses can maximize the potential of the machine without the need for extensive training or specialized expertise.In addition to its impressive technical capabilities, (Company Name) understands the importance of providing exceptional customer support. The company's team of experienced professionals is dedicated to assisting clients every step of the way, from the initial inquiry to after-sales service. This commitment to customer satisfaction sets (Company Name) apart from its competitors and has earned it a reputation for reliability and trustworthiness.The introduction of the Roof Tin Making Machine marks a significant milestone for (Company Name) and the manufacturing industry as a whole. As the demand for roofing materials continues to grow, businesses are constantly seeking ways to improve their production processes and stay ahead of the competition. The Roof Tin Making Machine offers a solution that not only meets but exceeds these expectations, setting a new standard for efficiency and quality in roof tin manufacturing.Looking ahead, (Company Name) remains dedicated to pushing the boundaries of innovation and delivering cutting-edge solutions to its clients. With its unwavering commitment to excellence, the company is poised to continue making a positive impact on the manufacturing industry and beyond.In conclusion, the Roof Tin Making Machine represents a game-changing innovation for the manufacturing industry. Its advanced capabilities, combined with (Company Name)'s commitment to customer satisfaction, make it a valuable asset for businesses looking to elevate their production processes. As the demand for high-quality roofing materials continues to increase, the Roof Tin Making Machine is poised to revolutionize the way roof tins are manufactured, setting new standards for efficiency, quality, and reliability.

Europe Standard C Z Purlin Punching Holes Interchangeable Making Machine

Title: Advanced CZ Purlin Punching Holes Interchangeable Making Machine Sets New Industry StandardIntroduction (100 words):In an era marked by technological advancements and growing industrial demands, companies are continuously seeking innovative solutions to enhance efficiency and productivity. Recognizing this need, a leading manufacturing firm has successfully launched the all-new CZ Purlin Punching Holes Interchangeable Making Machine in Europe. Developed in accordance with the highest industry standards, this cutting-edge machine offers numerous benefits, from streamlining production processes to ensuring unparalleled accuracy. By removing specific brand names, we can focus on shed light on the machine's specifications, features, and potential impact on the market.Body:1. Industry Overview (150 words):The construction industry is witnessing a constant surge in demand, driving companies to adopt state-of-the-art machinery and equipment. CZ purlins, widely used in construction projects, provide structural support, making them crucial components. However, traditional manufacturing processes often present challenges in terms of efficiency, productivity, and accuracy. Addressing these concerns, the newly launched CZ Purlin Punching Holes Interchangeable Making Machine paves the way for enhanced production capabilities and superior quality outputs.2. Key Features and Specifications (200 words):The CZ Purlin Punching Holes Interchangeable Making Machine boasts several noteworthy features. Manufactured according to European standards, this machine ensures optimal performance and durability. Its punching holes are interchangeable, offering flexibility and versatility in shaping CZ purlins with different specifications. A robust hydraulic system facilitates smooth operations and consistent accuracy, reducing errors and enhancing overall output quality.Additionally, the machine incorporates advanced computer numerical control (CNC) technology. This cutting-edge system enables seamless integration with computer-aided design (CAD) software, enabling precise customization and design adjustments. As a result, manufacturers can effortlessly adapt to diverse project requirements while significantly shortening lead times.3. Advantages and Benefits (200 words):By utilizing the CZ Purlin Punching Holes Interchangeable Making Machine, manufacturers can experience a multitude of benefits. Notably, the machine streamlines the entire production process, enhancing efficiency and reducing operational costs. The interchangeable punching holes allow for quick reconfiguration, significantly enhancing flexibility and adaptability. This enables manufacturers to seamlessly switch between different CZ purlin specifications, minimizing downtime and maximizing productivity.Moreover, the precise punching process ensures superior quality outputs with minimal wastage. The machine's CNC integration further enhances accuracy and customization possibilities, allowing manufacturers to meet even the most intricate design requirements. By optimizing production processes, manufacturers can meet tight project deadlines, gain a competitive edge, and increase customer satisfaction.4. Market Outlook and Conclusion (150 words):The introduction of the CZ Purlin Punching Holes Interchangeable Making Machine signals a paradigm shift in the construction industry's manufacturing landscape. With its advanced features and adherence to European standards, this machine has the potential to disrupt the market by offering unparalleled efficiency and accuracy.As manufacturers become increasingly conscious of the need for sustainable practices and streamlined processes, the CZ Purlin Punching Holes Interchangeable Making Machine is well-positioned to cater to these demands. By investing in this innovative solution, companies can stay ahead of the competition, streamline production workflows, and optimize resource allocation.In conclusion, this new CZ Purlin Punching Holes Interchangeable Making Machine is poised to revolutionize the construction industry, delivering high-quality CZ purlins with precision and efficiency. With its ability to adapt to diverse project requirements, manufacturers can enhance productivity while meeting expanding market demands.

China Offers Comprehensive Roll Forming Solution for Diverse Applications

, Roll Forming Machine, Cold Roll Forming, China Roll Forming, One-Stop Solution, Consultation, Training, Applications.Roll forming is a common metal forming process used to shape metal into a specific profile or shape. It is achieved through a series of roll forming machines that progressively shape the metal until it reaches the desired shape. This process is commonly used in the production of metal building components, automotive parts, and consumer products.China is a major player in roll forming technology, with many domestic manufacturers providing roll forming machines and solutions. One of the leading manufacturers in China is MTC, which has built a reputation for providing high-quality roll forming machines and a one-stop solution for a range of applications.The MTC roll forming machine is a cold roll former, which means that it operates at room temperature. This is in contrast to hot roll forming, which requires the metal to be preheated before forming. The advantage of cold roll forming is that it can be used on a wider range of materials, including aluminum, steel, and other metals.MTC provides a comprehensive range of roll forming machines, including panel roll forming machines, roof panel machines, wall panel machines, and more. Each machine is tailored to the specific needs of the application, ensuring optimal performance and quality.One of the unique features of MTC is its one-stop solution for roll forming applications. This includes consultation, design, manufacturing, installation, and training. The MTC team works closely with clients to understand their needs and requirements, and then provides a tailored solution that meets those needs.The consultation phase is critical in determining the most appropriate roll forming machine for the specific application. MTC’s team of experts analyze factors such as the material being used, desired throughput, and other factors to recommend the best machine for the job.Once the design has been completed, MTC manufactures the roll forming machine to the highest standards. The company uses state-of-the-art equipment and processes to ensure maximum performance and reliability.Installation is carried out by MTC’s team of trained technicians, who work closely with the client to ensure that the machine is correctly installed and fully operational.Training is also a critical component of the MTC one-stop solution. The company provides comprehensive training to clients, ensuring that they are fully versed in the operation and maintenance of the roll forming machine. This ensures that clients are able to operate the machine to its full potential, and that any maintenance or repair needs are quickly identified and addressed.MTC’s one-stop solution has been successfully implemented across a range of applications, including building construction, automotive manufacturing, and consumer goods production. The company’s expertise and commitment to quality have made it a trusted partner for businesses around the world.In summary, MTC provides a one-stop solution for roll forming applications, including consultation, design, manufacturing, installation, and training. The company's cold roll forming machines are designed to deliver the highest levels of performance and reliability, and its team of experts works closely with clients to ensure that their specific needs are met. With a focus on quality and customer service, MTC is a trusted partner for businesses seeking roll forming solutions.

High-Quality Color Steel Sheeting Roofing Panel Cold Roll Forming Machine - Efficient and Easy to Operate This hand-operated rolling machine is an affordable and reliable solution for producing high-quality color steel sheeting roofing panels. It boasts low energy consumption and a yield strength of 32MPa, making it ideal for small-scale production. The equipment includes a roll forming system, hydraulic cutter, hydraulic station, electric control system, counter, and product supporter. With a processing speed of 8m/min and thickness range of 0.3-1mm, this machine is efficient and easy to operate.

, Sheet Hand Operated Rolling Machine, Cold Roll Forming Machine, Roofing Panel Roll Forming Machine, Mechanical Kingdom.Sheet Hand Operated Rolling Machine - A Reliable and Low-Cost Solution for Color Steel Sheeting Roofing Panel ManufacturingThe sheet hand operated rolling machine is a cost-effective and efficient solution for manufacturing color steel sheeting roofing panels. With its reliable working mechanism, easy operation, and low energy consumption, the machine is an excellent choice for small to medium-scale manufacturing units.Certificate and SpecificationsThe sheet hand operated rolling machine adheres to the CE certification and comes with a 7.5 KW main motor power and 4 KW hydraulic station power. The machine's sprocket is P-25.4, with 20 roller station capacity, which can produce a yield strength of up to 32MPa. The diameter of the principal axis is 70mm, and the roller material is made of 45# steel hard chrome plating. The machine can process sheets with a thickness of 0.3-1mm and has an installation dimension of about (L*W*H) 10*1.5*0.8M.Functional Features and AdvantagesThe sheet hand operated rolling machine is designed with several functional features that make it a robust and reliable option for color steel sheeting roofing panel manufacturing. Some notable features include:Low-Cost and High Efficiency: The machine is a low-cost and high-efficiency solution that can complete the manufacturing process quickly and efficiently.Reliable Working Mechanism: The machine's working mechanism is reliable, ensuring that the quality of the products is consistent.Easy Operation: The machine is easy to operate, even for those with no prior experience in the field.Low Energy Consumption: The machine consumes minimal energy, making it an eco-friendly option that reduces the energy bills.Equipment PartsThe machine includes several equipment parts, including roll forming, hydraulic cutter, hydraulic station, electric controlling system, counter, and product supporter. These parts work together to ensure that the machine can produce high-quality color steel sheeting roofing panels.Manufacturers of Roll Forming MachinesMechanical Kingdom is a renowned manufacturer of roll forming machines, operating in this field for the past 12 years. They offer a wide range of products, including tile-crushing computer control systems, ancient glazed tile copy machines, Laura machines, beam-free arch making machines, great-span, and beam-free structure equipment, as well as motor car plate making machines.ConclusionIn conclusion, the sheet hand operated rolling machine is a reliable, low-cost, and efficient solution for color steel sheeting roofing panel manufacturing. With its easy operation, low energy consumption, and robust working mechanism, it is an excellent choice for small to medium-scale manufacturing units. Mechanical Kingdom is a reputable manufacturer of roll forming machines, offering a range of products that cater to various requirements.

Innovative Light Gauge Forming Machine Revolutionizes Sheet Metal Industry

Introducing the Next Generation Light Gauge Forming Machine Revolutionizing the Construction IndustryIn today's fast-paced world, technology plays a crucial role in driving innovation across various industries. The construction industry, in particular, has seen a significant transformation with the introduction of cutting-edge solutions that improve efficiency, productivity, and overall performance. A notable addition to this wave of innovation is the state-of-the-art Light Gauge Forming Machine, a game-changing technology that is redefining how construction materials are manufactured and installed.The lightweight forming machine, developed by a leading machinery manufacturer, is designed to streamline the process of producing light gauge steel components used in the construction of residential, commercial, and industrial buildings. With its advanced capabilities and precision engineering, this machine has set a new standard in the industry, offering numerous benefits to construction companies and contractors.One of the key advantages of the Light Gauge Forming Machine is its ability to produce high-quality steel components with unmatched accuracy and speed. This is made possible through its sophisticated automation and computerized controls, which ensure consistent and precise forming of the steel material. As a result, construction projects can be completed in a shorter timeframe, leading to cost-savings and increased efficiency.Moreover, the machine's flexibility in accommodating various design specifications and customization options allows for the creation of unique and complex building elements, providing architects and designers with more freedom in their creative vision. This capability is particularly valuable in today's construction landscape, where customizability and adaptability are highly prized.In addition to its precision and versatility, the Light Gauge Forming Machine also boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. Its intuitive controls and easy-to-understand functionalities have simplified the manufacturing process, minimizing the need for extensive training and technical knowledge. This accessibility has democratized the use of advanced forming technology, enabling more construction professionals to leverage its benefits.Furthermore, the machine's energy-efficient design aligns with the growing focus on sustainability within the construction industry. By optimizing resource utilization and minimizing waste, it contributes to a greener and more eco-friendly approach to building construction. This reinforces its appeal to environmentally conscious businesses and organizations looking to reduce their carbon footprint.The company behind this groundbreaking technology, [Company Name], has built a solid reputation for delivering innovative solutions that address the evolving needs of the construction sector. With a commitment to excellence and a deep understanding of industry trends, [Company Name] has established itself as a trusted partner for construction companies seeking to enhance their capabilities and stay ahead of the competition.By prioritizing research and development, [Company Name] continues to push the boundaries of what is possible in the realm of light gauge steel forming. Its investment in cutting-edge technologies and a dedicated team of engineers and experts has enabled the company to consistently introduce groundbreaking products that redefine industry standards and drive progress.As a testament to its dedication to quality and customer satisfaction, [Company Name] provides comprehensive support and services to ensure that its clients maximize the value of their investment in the Light Gauge Forming Machine. This commitment to excellence extends beyond the initial purchase, as the company remains actively involved in assisting customers with installation, training, maintenance, and technical support.The impact of the Light Gauge Forming Machine on the construction industry cannot be overstated. Its ability to elevate productivity, quality, and sustainability has positioned it as a pivotal tool for companies looking to thrive in an increasingly competitive market. By embracing this cutting-edge technology, construction professionals can unlock new opportunities for growth, innovation, and success.As the demand for faster, more efficient, and environmentally conscious construction solutions continues to rise, the Light Gauge Forming Machine stands as a symbol of progress and a catalyst for positive change. [Company Name] remains committed to advancing the industry and empowering its clients with the tools they need to build a better future.

High-Quality Metal Roll Forming Machine Available for Purchase – Roof Panel Roll Forming Machine Supplier

Machine, Roll Forming Machine, Roof Panel Roll Forming Machine, Metal Roll Forming, Forming Machine, Metal Roll, Metal Roll Forming Machine for Sale, Buy Metal Roll Forming Machine, Metal Roll Forming Machine Wholesaler, Metal Roll Forming Machine Seller, Top-quality Metal Roll Forming Machine, Benefits of Using Metal Roll Forming Machine, Roll Forming Process, Metal Roll Forming vs Other Forming Techniques, Applications of Metal Roll Forming Machine, Factors to Consider when Buying Metal Roll Forming Machine.Title: Advancing Manufacturing with Metal Roll Forming MachineIntroduction:In the ever-evolving manufacturing industry, metal roll forming machines have become an essential tool for efficiently producing high-quality metal components. This blog will explore the benefits of using metal roll forming machines, discuss the roll forming process, compare metal roll forming with other forming techniques, highlight the applications of metal roll forming machines, and provide insights on factors to consider when purchasing these machines.Benefit 1: Top-quality Metal ComponentsMetal roll forming machines offer superior precision and accuracy in producing metal components. The continuous bending process ensures consistent dimensions, smooth edges, and precise shapes across multiple pieces, resulting in high-quality finished products. Additionally, the ability to control forming speeds and pressures allows for the production of complex and intricate designs, meeting various industry specifications.Benefit 2: Cost-effective ProductionMetal roll forming machines facilitate cost-effective production due to their ability to handle high volumes of material with minimal wastage. By using coil stock material, roll forming eliminates the need for traditional sheet metal blanks, reducing material costs and minimizing scrap. Furthermore, the continuous operation of roll formers decreases labor requirements and enhances production efficiency, ultimately reducing overall manufacturing costs.Benefit 3: Versatile ApplicationsMetal roll forming machines find applications in various industries, including automotive, construction, aerospace, and furniture. These machines offer versatility in creating a wide range of metal profiles, such as roof panels, wall cladding, gutters, window frames, and door frames. The flexibility in material thickness, width, and length allows manufacturers to cater to diverse customer requirements and adapt to market trends effectively.Roll Forming Process:The roll forming process involves feeding coil stock material into a series of contoured rolls, gradually bending and shaping the metal. As the material moves through multiple stations, the rolls progressively form the desired profile. Each station performs a specific shaping operation, such as punching, notching, embossing, or cutting. By adjusting the roll spacing, manufacturers can achieve precise dimensions and shapes. The formed metal components are then cut to the desired length using a flying shear or cut-off press.Metal Roll Forming vs Other Forming Techniques:Compared to other forming techniques like stamping and press braking, metal roll forming offers several advantages. First, roll forming allows for continuous production with minimal interruptions, reducing operational downtime. Second, roll forming eliminates the need for pre-formed blanks or separate operations for joining multiple pieces, resulting in faster production cycles. Finally, roll-formed components exhibit improved structural integrity due to the continuous grain flow, enhancing their strength and durability.Applications of Metal Roll Forming Machines:1. Automotive Industry: Metal roll forming machines are widely used in manufacturing automotive body components, including chassis, roof rails, door frames, and window frames. The ability to produce complex profiles and maintain tight tolerances makes roll forming an ideal choice for this industry.2. Construction Industry: Roll-formed profiles for roofing panels, wall cladding, and structural components are in high demand in the construction sector. The cost-effectiveness and precision of metal roll forming machines make them indispensable for producing these architectural elements.3. Furniture Industry: Roll forming technology is employed in the production of metal furniture components like frame elements, brackets, and decorative fittings. The versatility and high-quality output of metal roll forming machines contribute to the aesthetic appeal and functionality of modern furniture designs.Factors to Consider when Buying Metal Roll Forming Machines:1. Machine Size and Capacity: Consider the required profile dimensions, thickness, and material type to ensure compatibility with the selected machine's specifications.2. Material Handling and Coil Weight: Evaluate the machine's ability to handle heavy coil stock material and ensure that it suits your production requirements.3. Tooling Flexibility: Check if the machine allows for easy changeovers between different profiles and if additional tooling options are available to expand its capabilities.4. Automation and Integration: Decide if integrating automation features, like computer numerical control (CNC) systems, is necessary to enhance production efficiency and reduce human error.5. After-sales Support: Research the reputation of the manufacturer and evaluate the availability of technical support, spare parts, and maintenance services.Conclusion:Metal roll forming machines offer numerous benefits, including top-quality production, cost-effectiveness, and versatility. The roll forming process, with its continuous bending and shaping, ensures consistent dimensions and smooth edges. Metal roll forming outperforms other forming techniques in terms of efficiency, structural integrity, and faster production cycles. These machines find applications in diverse industries like automotive, construction, and furniture manufacturing. When purchasing a metal roll forming machine, considering factors such as machine size, capacity, tooling flexibility, and after-sales support will help manufacturers make informed decisions and achieve optimal results in their production processes.

High-quality Metal Roofing Sheet Roll Forming Machine for Efficient Production

Metal Roofing Sheet Roll Forming Machine Revolutionizes Roofing IndustryMetal roofing has become increasingly popular and widely used in the construction industry due to its durability, weather resistance, and aesthetic appeal. The process of manufacturing metal roofing sheets has now been revolutionized with the introduction of the state-of-the-art Metal Roofing Sheet Roll Forming Machine by [Company Name].[Company Name] is a leading manufacturer and supplier of roll forming equipment and has gained a reputation for producing high-quality and innovative machinery for the construction industry. The Metal Roofing Sheet Roll Forming Machine is the latest addition to their product line, and it has already begun to make waves in the roofing industry.The Metal Roofing Sheet Roll Forming Machine is designed to efficiently produce metal roofing sheets of various profiles and dimensions. With its advanced technology and precision engineering, the machine is capable of forming and cutting metal coils into perfectly shaped roofing panels with minimal waste and maximum efficiency.One of the key features of the Metal Roofing Sheet Roll Forming Machine is its versatility. It is designed to accommodate different types of metal coils, including galvanized steel, aluminum, and copper, allowing for a wide range of options for roofing materials. This versatility has made the machine a popular choice among roofing manufacturers and contractors who work with various types of metal roofing materials.In addition to its versatility, the Metal Roofing Sheet Roll Forming Machine is also known for its speed and reliability. The machine is capable of producing roofing panels at a high rate of speed, making it a valuable asset for manufacturers who require large volumes of metal roofing sheets. Furthermore, its robust design and quality components ensure consistent and reliable performance, minimizing downtime and production delays.Moreover, the Metal Roofing Sheet Roll Forming Machine is designed with user-friendly features that make it easy to operate and maintain. The intuitive controls and automated functions streamline the production process, reducing the need for manual labor and increasing overall productivity. This user-friendly design has been well-received by operators and technicians who appreciate the machine's efficiency and ease of use.As a leading manufacturer and supplier of roll forming equipment, [Company Name] has a strong track record of providing reliable machinery and exceptional customer support. The Metal Roofing Sheet Roll Forming Machine is no exception, as it comes with comprehensive training and technical support to ensure that customers can maximize the machine's capabilities and maintain optimal performance.The introduction of the Metal Roofing Sheet Roll Forming Machine has had a significant impact on the roofing industry, as it has redefined the way metal roofing sheets are manufactured. Its advanced technology, versatility, speed, and reliability have set a new standard for roofing manufacturers and contractors, allowing them to meet the growing demand for high-quality metal roofing products.In conclusion, the Metal Roofing Sheet Roll Forming Machine by [Company Name] represents a significant advancement in the roofing industry. Its innovative features and capabilities have captured the attention of manufacturers and contractors who seek to streamline their production processes and deliver top-notch metal roofing products. As metal roofing continues to gain popularity in the construction industry, the Metal Roofing Sheet Roll Forming Machine is poised to play a crucial role in meeting the market's demand for efficient and high-quality roofing solutions.