- Home

- News

- High-quality Horizontal Panel Roll Forming Machine: A Cost-effective Solution for Sheet Metal Fabrication

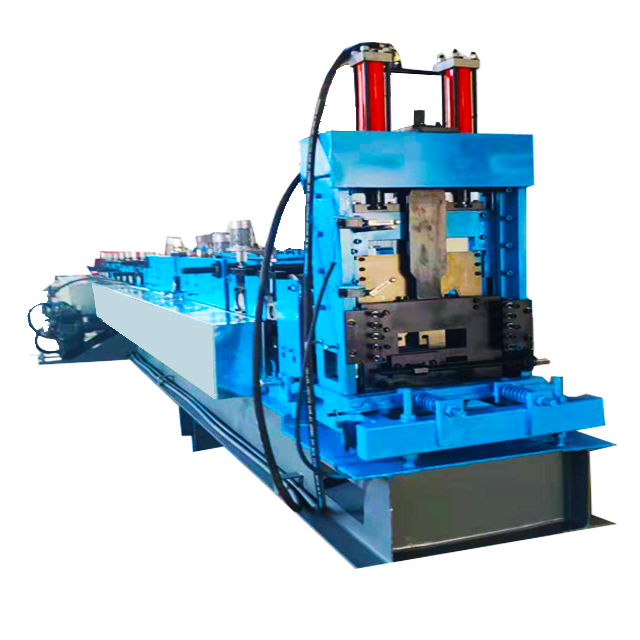

High-quality Horizontal Panel Roll Forming Machine: A Cost-effective Solution for Sheet Metal Fabrication

By:Admin

The metal sheet production industry has witnessed a major breakthrough with the introduction of the Horizontal Panel Roll Forming Machine by a leading manufacturing company. This innovative machine is set to revolutionize the way metal sheets are formed, offering increased efficiency, precision, and flexibility in production processes.

The Horizontal Panel Roll Forming Machine is designed to create flat, uniform panels from metal sheets, with a horizontal orientation that allows for continuous production. This eliminates the need for manual manipulation of the metal sheets, reducing production time and ensuring consistent quality throughout the process. With its advanced technology and precision engineering, this machine is poised to become an essential tool for metal sheet manufacturers around the world.

The company behind this groundbreaking machine, {}, is a renowned leader in the design and manufacture of roll forming equipment. With over 20 years of experience in the industry, they have earned a reputation for delivering high-quality, reliable machines that meet the diverse needs of their customers. From automotive to construction, their roll forming machines have been integral in the production of a wide range of products.

Notably, the Horizontal Panel Roll Forming Machine offers a range of benefits that set it apart from traditional roll forming equipment. Its horizontal orientation allows for seamless integration into existing production lines, making it an ideal solution for manufacturers looking to upgrade their processes without significant disruptions. Additionally, its high-speed operation and robotic control system ensure consistent and precise panel formation, reducing material waste and enhancing overall productivity.

One of the key features of this machine is its versatility in forming different types of metal sheets. Whether it's aluminum, steel, or other metals, the Horizontal Panel Roll Forming Machine can accommodate a variety of materials, making it suitable for a wide range of applications. This flexibility opens up new possibilities for manufacturers, allowing them to adapt to changing market demands and explore new opportunities for their products.

Furthermore, the machine's user-friendly interface and automation capabilities make it easy to operate and maintain, reducing the need for specialized training and technical expertise. This ensures that manufacturers can quickly integrate the machine into their production processes and start reaping the benefits of enhanced efficiency and output.

The company's commitment to innovation and customer satisfaction is reflected in the development of the Horizontal Panel Roll Forming Machine. By leveraging cutting-edge technology and industry expertise, they have created a machine that addresses the evolving needs of the metal sheet production industry, empowering manufacturers to stay ahead of the competition and deliver high-quality products to their customers.

In conclusion, the introduction of the Horizontal Panel Roll Forming Machine marks a significant milestone in the metal sheet production industry. With its advanced features, versatility, and user-friendly design, it is set to redefine the way metal sheets are formed, offering manufacturers a competitive edge in an increasingly demanding market. As {} continues to lead the way in roll forming innovation, the future looks bright for manufacturers seeking to elevate their production capabilities and achieve greater success in the industry.

Company News & Blog

Promotional Corrugated Pipe Machine for PC Solid and Transparent Sheet Manufacturing Line

Title: Enhancing Productivity with Advanced Corrugated Sheet Manufacturing MachineIntroduction:In this era of rapid industrialization and infrastructure development, the demand for high-quality and efficient manufacturing machines is skyrocketing. One such revolutionary machine gaining popularity is the Corrugated Sheet Manufacturing Machine. Let's delve into the technical specifications and product features that make this machine a game-changer.Technical Specifications:The Corrugated Sheet Manufacturing Machine offered by JEEBO Machinery is a state-of-the-art unit designed to produce various types of corrugated sheets. With a width capacity of up to 30000mm and a thickness range of 0.8-15mm, this machine ensures unparalleled flexibility in meeting diverse industry requirements.Product Features and Applications:1. PC.PMMA.PS Optical Transparent Plate:The first impressive feature of this machine is its ability to manufacture optical transparent plates made from PC (Polycarbonate), PMMA (Polymethyl Methacrylate), and PS (Polystyrene). These durable and visually appealing plates find applications in screens, advertising materials, and article lenses. By offering a wide range of options in terms of width and thickness, this machine caters to the specific needs of various industries.2. PC Everlasting Plate PMMA PS Color and Carved:Another remarkable aspect is the machine's capability to produce everlasting plates using PC, PMMA, and PS materials. These plates are known for their long-lasting and robust qualities, making them suitable for applications in advertising materials, architectural elements, and many more. Moreover, the machine can create color and carved plates, adding a decorative aspect to the finished products.3. Enhanced Productivity:The Corrugated Sheet Manufacturing Machine by JEEBO Machinery not only delivers superior quality but also ensures high productivity. Equipped with cutting-edge technology, this machine streamlines the manufacturing process, enabling faster production cycles. The efficiency provided by this machine helps meet demanding deadlines and enhances overall productivity.4. Easy Operation and Maintenance:JEEBO Machinery understands the importance of user-friendliness. Hence, the Corrugated Sheet Manufacturing Machine is designed for easy operation and maintenance. The machine's intuitive control panel allows operators to adjust settings and parameters effortlessly. Additionally, routine maintenance tasks are simplified, ensuring smooth and uninterrupted production operations.Conclusion:In today's competitive market, having the right manufacturing equipment is vital for business success. The Corrugated Sheet Manufacturing Machine from JEEBO Machinery has emerged as a reliable and efficient solution in the industry. With its impressive technical specifications and versatile applications, this machine enables manufacturers to meet diverse demands while enhancing productivity. Investing in this cutting-edge machine will undoubtedly boost manufacturing capabilities and position businesses for long-term growth.Keywords: Corrugated Sheet Manufacturing Machine, PC Transparent Plate, PMMA Plate, PS Plate, everlasting plate, color plate, carved plate, productivity, manufacturing equipment, JEEBO Machinery.

Advanced Length Cutting Machine for Precision Cuts

Automatic Length Cutting Machine Revolutionizes Manufacturing Process for [Company Name][City, State] - [Company Name], a leading manufacturing company in the [industry] sector, has recently introduced a state-of-the-art Automatic Length Cutting Machine to their production line. This cutting-edge technology has revolutionized the manufacturing process, allowing for more efficient and precise cutting of materials, ultimately enhancing the overall product quality and production output.The Automatic Length Cutting Machine, which is designed and developed in-house by [Company Name] engineers, utilizes the latest automation and software technology to accurately measure, cut, and process various materials such as steel, aluminum, and other metals. The machine is equipped with advanced sensors and controls that ensure precise cutting according to the required specifications, reducing material waste and minimizing human error."We are thrilled to introduce this cutting-edge Automatic Length Cutting Machine to our production line," said [Name], CEO of [Company Name]. "This technology represents a significant advancement in our manufacturing capabilities, allowing us to achieve higher levels of precision and efficiency in our production processes. It also reflects our commitment to innovation and delivering high-quality products to our customers."The implementation of the Automatic Length Cutting Machine has had a profound impact on [Company Name]'s manufacturing operations. With its ability to accurately cut materials to the required length and specifications, the company has experienced a significant reduction in production time and costs. Additionally, the machine's automation capabilities have freed up labor resources, allowing employees to focus on more intricate and value-added tasks within the production process.Furthermore, the precise cutting enabled by the Automatic Length Cutting Machine has resulted in a higher quality end product. This has been well-received by [Company Name]'s customers, who have noted the improvement in the consistency and accuracy of the materials used in their projects.In addition to the technical capabilities of the Automatic Length Cutting Machine, [Company Name] has also focused on the machine's user-friendly interface and easy integration with their existing production systems. This has allowed for a seamless transition and adoption of the new technology within their manufacturing facility."We have been thoroughly impressed with the performance and reliability of the Automatic Length Cutting Machine," said [Name], a production manager at [Company Name]. "The machine's intuitive interface and seamless integration with our existing systems have made the transition smooth, and we have seen tangible improvements in our production efficiency and product quality."Looking ahead, [Company Name] is committed to further enhancing the capabilities of the Automatic Length Cutting Machine, with plans to integrate more advanced features and functionalities in future iterations. The company also aims to explore opportunities to customize the technology to meet the specific needs of different industries and applications, expanding its market reach and potential impact.The introduction of the Automatic Length Cutting Machine has firmly positioned [Company Name] as a pioneer in the industry, setting new standards for manufacturing efficiency and quality. With its focus on innovation and commitment to delivering exceptional products, [Company Name] continues to lead the way in transforming the manufacturing landscape.As [Company Name] looks to the future, the Automatic Length Cutting Machine will undoubtedly play a pivotal role in driving the company's growth and cementing its reputation as a trusted partner for high-quality, precision-engineered products in the [industry] sector.For more information about [Company Name] and its range of products and services, please visit [company website].Contact:[Name][Title][Company Name][Phone Number][Email Address]

Guide to Choosing a Metal Roof Forming Machine

Metal Roof Forming Machine Innovates the Roofing IndustryAs the roofing industry continues to evolve, the demand for high-quality, durable, and efficient metal roofing materials has seen a significant rise in recent years. With this increasing demand, companies like [Company Name] have stepped up to the plate to provide cutting-edge solutions to meet the industry's needs. [Company Name] has recently unveiled their latest innovation – the Metal Roof Forming Machine, a technology that is set to revolutionize the way metal roofing materials are manufactured.The Metal Roof Forming Machine is a state-of-the-art piece of equipment that is designed to streamline the process of forming metal roofing materials. This machine boasts a number of advanced features that set it apart from traditional metal forming equipment, making it an indispensable tool for roofing manufacturers looking to improve their production processes.One of the standout features of the Metal Roof Forming Machine is its high level of automation. This machine is equipped with advanced computerized controls that allow for precise and efficient metal forming, reducing the margin of error and ensuring consistently high-quality finished products. This level of automation also means that the machine requires minimal human intervention, resulting in lower labor costs and a more efficient production line overall.In addition to its automation capabilities, the Metal Roof Forming Machine also offers a high level of flexibility. This machine is capable of producing a wide range of metal roofing materials, including panels of different sizes, shapes, and profiles. This versatility allows manufacturers to meet the diverse needs of their customers without having to invest in multiple pieces of equipment, making it a cost-effective solution for businesses of all sizes.Furthermore, the Metal Roof Forming Machine is designed with the end user in mind. Its user-friendly interface and intuitive controls make it easy for operators to set up and oversee the metal forming process, reducing the need for extensive training or specialized expertise. This accessibility ensures that manufacturers can quickly integrate the machine into their existing production line, minimizing downtime and maximizing productivity.With the introduction of the Metal Roof Forming Machine, [Company Name] has solidified its position as a leader in the roofing industry. This innovative technology is a testament to the company's commitment to pushing the boundaries of what is possible in the manufacturing of roofing materials, and represents a significant step forward for the industry as a whole.In addition to its cutting-edge technology, [Company Name] also prides itself on its commitment to sustainability and environmental responsibility. The Metal Roof Forming Machine is designed to minimize material waste and energy consumption, making it a greener alternative to traditional metal forming methods. By reducing the environmental impact of the manufacturing process, [Company Name] is demonstrating its dedication to developing solutions that are not only efficient and cost-effective but also environmentally friendly.The Metal Roof Forming Machine is already making waves in the roofing industry and has garnered significant interest from manufacturers looking to improve their production processes. With its advanced features, flexibility, and commitment to sustainability, this technology is set to redefine the way metal roofing materials are manufactured, setting a new standard for the industry as a whole.In conclusion, the Metal Roof Forming Machine from [Company Name] represents a significant leap forward for the roofing industry. With its advanced technology, efficiency, and sustainability, this innovation is set to revolutionize the way metal roofing materials are manufactured, providing manufacturers with a cost-effective, user-friendly, and environmentally responsible solution. As the demand for metal roofing continues to grow, the Metal Roof Forming Machine is poised to play a pivotal role in shaping the future of the industry.

9ct Rose Gold Cubic Zirconia Full Eternity Stacker Ring with Round Brilliant Cut Channel Set

Title: The Allure of the Stacker for the CZ Purline Machine: Enhancing Your Jewelry CollectionIntroduction: Welcome to our blog on the fascinating world of high-quality jewelry. Today, we will be exploring the captivating style and craftsmanship of the Stacker for the CZ Purline Machine. Specifically, we will delve into the stunning 9ct Rose Gold Cubic Zirconia Round Brilliant Cut Channel Set Full Eternity Stacker Ring and its timeless appeal that resonates with jewelry enthusiasts around the world. Let's dive into this exceptional piece and discover how it can enhance your personal collection.1. Embracing the Stackable Trend:Stackable rings are a growing phenomenon in the world of fashion jewelry. The versatility of these pieces allows wearers to mix and match, creating unique and personalized combinations. The CZ Purline Machine's Stacker Ring is no exception. Its minimalist design flawlessly harmonizes with other rings, making it an ideal choice for those looking to make a statement.2. The Allure of Rose Gold:Rose gold has experienced a significant resurgence in popularity in recent years, captivating the hearts of fashion-forward individuals everywhere. The warm, rosy hue complements a variety of skin tones, adding a touch of elegance and sophistication to any outfit. With its 9ct composition, the Stacker Ring possesses a delicate balance of durability and subtlety.3. The Timeless Brilliance of Cubic Zirconia:Cubic Zirconia (CZ) is renowned for its remarkable similarity to diamonds, boasting an exceptional brilliance and clarity that make it an affordable alternative. The round brilliant-cut CZ stones in the Stacker Ring are meticulously set using the channel setting technique, ensuring maximum light reflection and an intense sparkle that catches the eye.4. Unmatched Elegance of the Full Eternity Design:The full eternity design of the Stacker Ring is nothing short of breathtaking. The channel-set CZ stones encircle the entirety of the band, symbolizing an everlasting bond and adding a touch of luxury. This timeless design is not only visually stunning but also holds significant sentimental value, making it an excellent choice for special occasions, anniversaries, or as a heartfelt gift.5. Crafting Excellence with CZ Purline Machine:The CZ Purline Machine revolutionizes the world of cubic zirconia jewelry, ensuring precise stone placement and meticulous craftsmanship. By utilizing advanced technology, the Stacker Ring is a testament to the manufacturer's dedication to excellence, resulting in a flawlessly executed piece that is sure to turn heads.Conclusion:In conclusion, the 9ct Rose Gold Cubic Zirconia Round Brilliant Cut Channel Set Full Eternity Stacker Ring is an exceptional addition to any jewelry collection. Its stackable nature allows for endless customization and versatility, while the rose gold and sparkling CZ stones offer timeless appeal. The craftsmanship and attention to detail, facilitated by the CZ Purline Machine, make this ring a true masterpiece. Elevate your style and leave a lasting impression with this stunning piece of jewelry.

Top Quality Roofing Making Machine for Sale - Ultimate Guide

Roofing Making Machine: A Game-Changer in the IndustryInnovation and advancement in technology are revolutionizing the way we do business and transforming various industries around the world. The roofing industry, in particular, has seen remarkable progress with the introduction of advanced machinery and equipment. One such groundbreaking development is the Roofing Making Machine produced by a leading company in the field of manufacturing and construction.The Roofing Making Machine is a state-of-the-art piece of equipment that has been designed and developed to streamline the process of manufacturing roofing materials. This machine is capable of producing high-quality roofing sheets with precision and efficiency, making it an essential asset for companies involved in the roofing industry.The company behind the development of this cutting-edge equipment is a renowned name in the manufacturing and construction sector. With a rich history of innovation and a commitment to excellence, the company has established itself as a global leader in providing advanced solutions for the production of building materials. Their expertise in engineering and manufacturing has enabled them to create a Roofing Making Machine that sets new standards in the industry.The Roofing Making Machine is equipped with advanced technology that allows for seamless and rapid production of roofing materials. It is capable of producing a wide range of roofing sheets, including corrugated, trapezoidal, and other custom designs, meeting the diverse needs of the market. The machine’s precise control and automated operation ensure consistent quality and uniformity in the manufactured roofing sheets, resulting in a superior end product.The efficiency and productivity of the Roofing Making Machine have been lauded by industry experts and customers alike. Its high-speed production capabilities and low maintenance requirements make it a cost-effective solution for companies looking to enhance their manufacturing processes. By significantly reducing the time and labor required for producing roofing materials, the machine enables businesses to increase their output and meet the growing demand in the market.Furthermore, the Roofing Making Machine incorporates features that prioritize safety and environmental sustainability. With comprehensive safety mechanisms and energy-efficient operations, the machine upholds the company’s commitment to responsible manufacturing practices. This aligns with the global movement towards environmentally friendly production methods, positioning the company as a responsible and conscientious industry leader.The company’s dedication to customer satisfaction is evident in its commitment to providing comprehensive support and training for clients who invest in the Roofing Making Machine. From installation and set-up to ongoing maintenance and technical assistance, the company ensures that its customers can maximize the benefits of their investment and optimize the performance of the equipment.The introduction of the Roofing Making Machine has created a significant impact on the roofing industry, empowering companies to elevate their manufacturing capabilities and deliver superior products to their customers. The machine’s advanced technology and efficiency have set a new benchmark for the industry, driving competitiveness and innovation in the market. Moreover, its adherence to safety and sustainability standards reflects the company’s vision for a progressive and responsible approach to business.In conclusion, the Roofing Making Machine produced by the pioneering company has emerged as a game-changer in the roofing industry. Its cutting-edge technology, robust performance, and commitment to excellence have redefined the manufacturing process for roofing materials, paving the way for enhanced productivity and quality. As the industry continues to evolve, the Roofing Making Machine stands as a testament to the power of innovation and engineering in creating transformative solutions for businesses. With its proven track record and customer-centric approach, the company and its revolutionary machine are poised to shape the future of the roofing industry.

Innovative Guardrail Forming Machine Revolutionizes Construction Methods

Title: Advanced Guardrail Forming Machine Introduces Innovation and Efficiency to Construction IndustryIntroduction:In recent years, the construction industry has witnessed significant advancements in technology and machinery. One such innovative solution is the advanced Guardrail Forming Machine, developed by a reputable industry leader. This revolutionary machine has been designed to streamline and enhance the process of manufacturing guardrails, promising improved productivity, durability, and safety measures. With its cutting-edge features and unparalleled capabilities, the Guardrail Forming Machine is set to revolutionize the construction industry and support infrastructure development projects worldwide.Streamlining Manufacturing Processes:Traditionally, the manufacturing of guardrails had been a labor-intensive and time-consuming process. However, the introduction of the Guardrail Forming Machine has revolutionized the production methods. This state-of-the-art machine automates several manual tasks, drastically reducing production time and effort. By eliminating the need for manual bending, cutting, and welding, the Guardrail Forming Machine ensures consistent precision and accuracy in every guardrail produced.Enhanced Efficiency and Productivity:The Guardrail Forming Machine incorporates advanced technology to deliver unmatched efficiency and productivity. Equipped with cutting-edge sensors and computerized controls, the machine ensures precise measurements and optimal material usage, significantly reducing wastage. With its high-speed production capabilities, the machine enables manufacturers to meet strict project deadlines while delivering superior quality guardrails consistently.Improved Safety Measures:Safety remains a paramount concern in the construction industry. The Guardrail Forming Machine addresses this aspect comprehensively, introducing numerous safety features to protect operators and workers. The machine includes automated mechanisms for material feeding, shaping, and cutting, reducing the risk of accidents caused by manual handling. Furthermore, it incorporates advanced safety sensors and emergency stop features, ensuring immediate response in case of any potential hazards.Durability and Longevity:Guardrails play a vital role in ensuring road safety, and their longevity is of utmost importance. The Guardrail Forming Machine operates with sturdy construction materials and meticulous engineering, ensuring the production of durable and long-lasting guardrails. By employing the precise shaping and welding processes, the machine creates homogeneous and seamless guardrail sections that are highly resistant to wear and tear, adverse weather conditions, and impact damage.Environmentally-Friendly Manufacturing:In addition to its numerous excellent features, the Guardrail Forming Machine also prioritizes sustainability and environmental consciousness. The machine incorporates energy-efficient mechanisms that minimize power consumption during the manufacturing process. Furthermore, the reduction in material wastage, as a result of precise measurements, contributes to a more sustainable manufacturing process in comparison to traditional methods. Manufacturers can rely on this advanced machine to align their production processes with modern environmental preservation standards.Global Impact on Infrastructure Development:With the ever-increasing demands of infrastructure development projects globally, the introduction of the Guardrail Forming Machine serves as a boon for construction companies. Its ability to produce a large volume of guardrails with unparalleled precision and efficiency creates a positive impact on project timelines and budgets. Additionally, the durability and safety aspects of these guardrails ensure the longevity and effectiveness of road safety measures, enhancing the overall quality of infrastructure projects worldwide.Conclusion:The revolutionary Guardrail Forming Machine has redefined the manufacturing process of guardrails in the construction industry. By incorporating advanced technology, it streamlines production, enhances efficiency, and improves safety measures. Furthermore, its environmental-friendly features contribute to sustainable manufacturing practices. As a result, the machine is set to play a pivotal role in infrastructure development projects globally, ensuring the production of high-quality guardrails that guarantee long-term road safety. Construction companies worldwide can now rely on this advanced machinery to meet strict project requirements and take a significant step towards a more productive and sustainable future.

Lightweight Zinc-coated Steel Purlins for Efficient Roofing and Cladding Support in Metal Buildings

article about the benefits of using C & Z section purlins for roofing and cladding support in framed structures.Purlins may be one of the less glamorous components of a building, but they play a critical role in supporting the roof and walls. As static elements, they help distribute the weight of the roof and the wind loads to the main frame of the building. Traditionally, purlins were made of wood, but with the development of new materials and manufacturing techniques, steel purlins have become the preferred choice for modern constructions.Among steel purlins, C & Z section purlins are the most commonly used types for roofing and cladding support in framed structures. C section purlins have a C-shaped cross-section, while Z section purlins have a Z-shaped cross-section. Both types are made of high-strength zinc-coated steel, which provides corrosion resistance and durability.Arkhon, a leading manufacturer of roll-forming machines and steel components for the construction industry, offers a range of C & Z section purlins that are accurately roll-formed for optimal performance. The company's purlins are lightweight, economical, and easy to install, making them an excellent choice for a wide range of applications, from agricultural buildings to industrial warehouses.One of the key benefits of using Arkhon C & Z section purlins is their efficiency. By using high-strength steel, the purlins can support a considerable amount of weight while remaining lightweight. This means that less steel is needed, which reduces the overall cost of the building. Moreover, the purlins' design allows for better load distribution, which minimizes the risk of roof sagging or collapse.Another advantage of Arkhon's C & Z section purlins is their versatility. The purlins come in different sizes and thicknesses, allowing builders to choose the best option for their specific project. Additionally, the purlins can be easily cut to length on-site, which simplifies the installation process and minimizes waste.Arkhon's C & Z section purlins are also highly durable and require minimal maintenance. The zinc-coated steel provides excellent corrosion resistance, which extends the lifespan of the purlins. Furthermore, the purlins' design allows for good drainage and ventilation, reducing the risk of moisture buildup and mold growth.Finally, Arkhon's C & Z section purlins are environmentally friendly. Steel is a highly recyclable material, which means that the purlins can be repurposed at the end of their lifespan. Additionally, the purlins' efficient design and reduced steel usage contribute to a more sustainable construction process.In conclusion, Arkhon's C & Z section purlins are an excellent choice for roofing and cladding support in framed structures. Their efficiency, versatility, durability, and eco-friendliness make them a reliable and cost-effective solution for a wide range of applications. With Arkhon's precision manufacturing and high-quality materials, builders can rest assured that their purlins will provide optimal support for their building.

High-Quality Metal Slitting Line for Sale – Different Gauges Available at SteelSlitter.com

RISHBIN Emerges as a Leading Slitting Line Machine Manufacturer Offering High-Quality Metal Slitting Line for SaleIn the dynamic world of manufacturing, industries are constantly seeking efficient and reliable solutions to meet their production needs. RISHBIN, a prominent player in the market, has emerged as one of the best slitting line machine manufacturers, offering high-quality metal slitting lines for sale. With a wide range of machines catering to different gauge requirements, RISHBIN continues to revolutionize the industry with its cutting-edge technology and exceptional product offerings.Slitting lines are a vital component of the metal processing industry, enabling precise cutting and resizing of coils into narrower widths. When it comes to manufacturing slitting line machines, RISHBIN stands out for its commitment to delivering superior quality and innovative features. With an experienced team of engineers and technicians, the company is at the forefront of technological advancements, ensuring that their machines meet the highest industry standards.RISHBIN's metal slitting lines are designed to handle various gauge requirements, ensuring flexibility and versatility for a wide range of applications. The availability of machines suitable for light, medium, and heavy gauge materials makes RISHBIN the go-to manufacturer for businesses operating in diverse sectors. Whether it's the automotive, construction, or packaging industry, RISHBIN's slitting lines provide optimal performance and accuracy.What sets RISHBIN apart from its competitors is its continuous focus on research and development. The company invests heavily in innovation, constantly enhancing its product offerings to meet evolving industry demands. By staying up-to-date with the latest technological advancements, RISHBIN ensures that its slitting line machines provide the most efficient and reliable solutions for its customers.In addition to its dedication to quality and innovation, RISHBIN is also renowned for its exceptional customer service. The company believes in establishing long-term relationships with its clients, prioritizing their needs and exceeding their expectations. RISHBIN's team of experts assists customers throughout the entire purchasing process, offering valuable guidance and support to help them make informed decisions.RISHBIN's commitment to quality and customer satisfaction is further reflected in its post-sales services. The company offers comprehensive maintenance and technical support to ensure that its machines continue to perform optimally throughout their lifespan. By providing timely servicing and spare parts availability, RISHBIN helps its customers maximize their productivity and minimize downtime.With its robust manufacturing capabilities, RISHBIN ensures that each slitting line machine is crafted to perfection. The company utilizes high-quality materials and rigorous quality control processes to guarantee the durability and efficiency of its products. RISHBIN's metal slitting lines are built to withstand heavy usage and deliver consistent performance, making them a reliable investment for businesses looking to enhance their manufacturing processes.As a socially responsible organization, RISHBIN is committed to sustainability and environmentally friendly practices. The company implements energy-efficient measures throughout its manufacturing processes, reducing its carbon footprint and promoting a greener future. By choosing RISHBIN's slitting line machines, customers not only benefit from high performance but also contribute to global sustainability efforts.In conclusion, RISHBIN has established itself as a leading slitting line machine manufacturer by delivering high-quality solutions tailored to different gauge requirements. With its focus on innovation, customer service, and sustainability, RISHBIN continues to drive the industry forward. As businesses strive for excellence in their manufacturing processes, RISHBIN's metal slitting lines emerge as the ideal choice, ensuring efficiency, accuracy, and long-term reliability.

Discover the Latest Advancements in Roofing Metal Forming Machines

Roofing Metal Forming Machine Offers an Efficient Solution for Manufacturing Metal Roofing SheetsRoofing Metal Forming Machine (need remove brand name), a leading manufacturer and supplier of metal forming machines, offers an efficient solution for producing metal roofing sheets. The machine is designed to provide a cost-effective and reliable method for manufacturing roofing sheets while meeting the required specifications.The company has gained a reputation as a trusted supplier of metal forming machines due to its focus on quality, reliability, and innovation. By combining advanced technology with skilled engineering, the company has created a range of metal forming machines that offer superior performance, efficiency, and durability.The Roofing Metal Forming Machine (need remove brand name) is an excellent example of the company's commitment to innovation and quality. The machine is designed to produce high-quality roofing sheets with consistent thickness, length, and width. It is capable of processing different types of metal, including steel, aluminum, and copper, with varying thicknesses and widths.One of the main advantages of the Roofing Metal Forming Machine (need remove brand name) is its versatility. The machine can be customized to produce roofing sheets of different profiles, including corrugated, trapezoidal, and standing seam profiles. This flexibility enables manufacturers to cater to different market requirements and produce roofing sheets that meet the specific needs of their customers.The machine is also easy to operate, thanks to its user-friendly interface and automated features. The operator can easily program the machine to produce roofing sheets with the desired length and width, and the machine will automatically adjust its settings to ensure consistent quality and accuracy.The Roofing Metal Forming Machine (need remove brand name) is also designed to reduce material waste, which is a major concern for manufacturers in the metal forming industry. The machine is equipped with a precision cutting system that minimizes material waste and ensures optimal usage of raw materials.In addition to its outstanding performance and efficiency, the Roofing Metal Forming Machine (need remove brand name) is also known for its durability and low maintenance requirements. The machine is built to withstand heavy-duty usage and can operate continuously for extended periods with minimal downtime.The company offers comprehensive support services to ensure that its customers get the most out of their investment in the Roofing Metal Forming Machine (need remove brand name). The services include installation, training, and ongoing technical support, which enable customers to operate the machine efficiently and maximize their production output.Overall, the Roofing Metal Forming Machine (need remove brand name) is a reliable and cost-effective solution for manufacturing high-quality metal roofing sheets. Its advanced features, versatility, and user-friendly interface make it an excellent choice for manufacturers looking to optimize their production processes and increase their competitiveness in the market.About the CompanyRoofing Metal Forming Machine (need remove brand name) is a leading manufacturer and supplier of metal forming machines. The company specializes in designing and producing machines for the metal roofing and cladding industry, including roll forming machines, slitting machines, and cut-to-length machines.The company has been in business for over 20 years and has gained a reputation for its commitment to quality, reliability, and innovation. Its machines are used by manufacturers in various industries across the world, including Europe, North America, South America, Africa, and Asia.Roofing Metal Forming Machine (need remove brand name) has a team of skilled engineers and technicians who use advanced technology and materials to create machines that meet the highest standards. The company also offers comprehensive support services, including installation, training, and technical support, to ensure that its customers get the most out of their investment.

Roll Forming Machine, Cold Roll Forming Machine, Sandwich Panel Machine, Roof Tile Roll Forming Machine, Wall Panel Roll Forming Machine, Steel Roll Forming Machine, Glazed Tile Roll Forming Machine, Ridge Cap Roll Forming Machine, IBR Roll Forming Machine, Corrugated Roll Forming Machine, Floor Deck Roll Forming Machine, Highway Guardrail Roll Forming Machine, Stud and Track Roll Forming Machine, Furring Channel Roll Forming Machine, Downpipe Roll Forming Machine, Gutter Machine, Roller Shutter Door Forming Machine, K Span Roll Forming Machine, Door Frame Roll Forming Machine, Standing Seam Roof Panel Roll Forming Machine, Bemo Panel Roll Forming Machine, Shelf Roll Forming Machine, Cable Tray Roll Forming Machine, Slitting & Cutting Machine, Roof Curving Machine, Embossing Machine

Title: Innovations in Roll Forming Machines - Revolutionizing Construction IndustryIntroduction:In the rapidly evolving construction industry, the use of advanced machinery and equipment has become crucial to enhance productivity and efficiency. Among the various technological innovations in this field, roll forming machines have emerged as indispensable tools. These machines play a pivotal role in the production of metal sheets and panels used in roofing, wall cladding, and other construction applications.Roll Forming Machine: Transforming Metal Sheets with PrecisionRoll forming machines, also known as roll formers, are highly versatile manufacturing machines used to transform flat metal sheets into complex and customized profiles used in construction. They utilize a continuous bending operation by passing the sheet metal through a series of rolling dies. The process involves shaping the metal into a desired cross-section profile while maintaining uniform thickness throughout the length.Cold Roll Forming Machine: Enhancing Precision and DurabilityCold roll forming machines have gained immense popularity due to their ability to work with a wide range of materials, including steel, aluminum, copper, and more. This type of roll forming machine operates at room temperature, minimizing the risk of thermal damage to the metal. Cold roll forming ensures higher uniformity in the end products, offering superior dimensional accuracy, strength, and durability.Sandwich Panel Machine: Efficient Insulation SolutionsThe use of sandwich panels in construction has gained significant traction, primarily due to their excellent thermal and sound insulation properties. Sandwich panel machines are specifically designed to produce panels with an insulating core material, such as EPS (Expanded Polystyrene), rock wool, or mineral wool, sandwiched between two outer sheets. These panels find applications in roofing, wall cladding, and other structural elements, offering energy efficiency and environmental benefits.Revolutionizing the Manufacturing Process:- EPS/Rock wool/Mineral wool sandwich panel machine: This advanced technology enables the efficient production of insulated panels, offering enhanced temperature regulation and noise reduction in buildings.- Glazed Tile Roll Forming Machine: Utilizing high-quality materials, this machine produces aesthetically appealing glazed tiles for roofing applications. The precise roll forming process ensures dimensional accuracy and long-lasting performance.- Standing Seam Roof Panel Roll Forming Machine: This machine revolutionizes the production of standing seam roof panels, which are popular for their exceptional weather resistance and stylish appearance.- Double Layer Roll Forming Machine: Ideal for large-scale projects, this machine efficiently produces two different profiles simultaneously, reducing production time and costs.- Highway Guardrail Roll Forming Machine: As road safety remains a paramount concern, this machine manufactures sturdy guardrails, protecting motorists and minimizing accidents.Expanding Possibilities with Advanced Features:Modern roll forming machines come equipped with advanced features such as computer numerical control (CNC) systems, automated feeders, and precision cutting mechanisms, ensuring high productivity, reliability, and time efficiency. These features allow for customization and adaptation to different profile designs.Conclusion:The roll forming machine industry has witnessed substantial advancements in recent years, fueling innovative manufacturing processes in the construction sector. The introduction of cold roll forming machines, sandwich panel machines, and other specialized equipment has enabled the production of high-quality, customized metal profiles and panels. As technology continues to evolve, these machines will play a vital role in shaping the infrastructure of our future.For further information or inquiries, interested parties are encouraged to contact Ms. Monica Lee, who will provide detailed information and the best prices for the required profile drawings or specifications.Contact Person: Ms. Monica LeeWebsite: (brand name removed)Disclaimer: This news content is for information purposes only and does not serve as an endorsement for any specific brand or company.