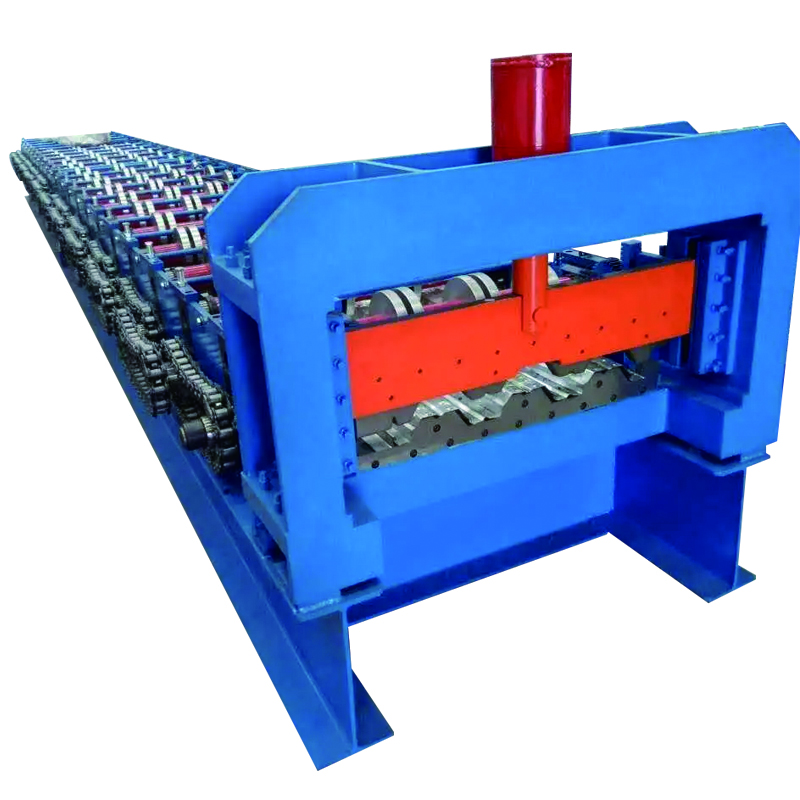

High-quality Metal Roof Panel Making Machine for Efficient Roofing Production

By:Admin

In a world where efficiency and productivity are key factors in maintaining a competitive edge, the construction industry is constantly seeking innovative solutions to streamline operations. One such groundbreaking solution is the Metal Roof Panel Making Machine, which has been developed by a leading industry player, known for its expertise in manufacturing high-quality machinery for the construction sector.

The Metal Roof Panel Making Machine is designed to revolutionize the process of manufacturing metal roof panels, which are an essential component in modern building construction. These panels are not only durable and low-maintenance but also provide a sleek and contemporary appearance, making them a popular choice for commercial and residential buildings alike.

This state-of-the-art machine is equipped with advanced technology and automation, allowing for the seamless production of metal roof panels with precision and speed. It is capable of handling various types of metal materials, including steel, aluminum, and copper, and can produce panels of different shapes, sizes, and designs to cater to diverse project requirements.

One of the key features that set this Metal Roof Panel Making Machine apart from traditional manufacturing methods is its ability to significantly reduce production time and labor costs. The machine's automated processes minimize the need for manual intervention, thereby optimizing efficiency and maximizing output. This not only benefits manufacturers by improving their bottom line but also translates to faster turnaround times for construction projects, ultimately benefiting the end-users.

Furthermore, the Metal Roof Panel Making Machine boasts a user-friendly interface and intuitive controls, making it accessible to operators with varying levels of expertise. Its robust construction and reliable performance ensure consistent quality and durability of the produced panels, meeting the stringent standards of the construction industry.

The company behind this groundbreaking innovation has a long-standing reputation for excellence in the field of construction machinery. With a focus on research and development, they have continuously strived to introduce cutting-edge solutions that address the evolving needs of the industry. Their commitment to quality, coupled with a customer-centric approach, has made them a trusted partner for construction companies worldwide.

In addition to producing the Metal Roof Panel Making Machine, the company offers comprehensive support services, including installation, training, maintenance, and technical assistance. This full-service approach ensures that customers can harness the full potential of the machine, maximizing its performance and longevity.

As the demand for metal roof panels continues to rise in the construction sector, the Metal Roof Panel Making Machine is poised to play a pivotal role in meeting this demand and setting new benchmarks for efficiency and excellence. Its impact is not limited to large-scale manufacturers but extends to contractors, builders, and developers who rely on high-quality metal roof panels to deliver exceptional results in their projects.

In conclusion, the Metal Roof Panel Making Machine represents a game-changing innovation that is reshaping the landscape of the construction industry. With its advanced technology, automation, and superior performance, it is poised to elevate production standards and set a new paradigm for metal roof panel manufacturing. As the industry embraces this revolutionary solution, it is evident that the future of construction is being shaped by forward-thinking companies and their commitment to driving progress through innovation.

Company News & Blog

High Quality Roof Tin Making Machine for Sale - Find Out More Here!

Roof Tin Making Machine Revolutionizes the Manufacturing IndustryRoofing has long been an essential component of construction, and the demand for high-quality roofing materials continues to grow. In response to this increasing demand, (Company Name) unveils its latest innovation - a state-of-the-art Roof Tin Making Machine.With over 20 years of experience in the manufacturing industry, (Company Name) has established itself as a leading provider of machinery and equipment for the construction and building materials sector. The company's commitment to innovation and quality has made it a trusted partner for businesses around the world.The Roof Tin Making Machine is the latest addition to (Company Name)'s impressive portfolio of products. This cutting-edge machine is designed to streamline the production process for roofing materials, significantly increasing efficiency and reducing labor costs. By investing in this advanced technology, businesses can expect to see a significant improvement in their bottom line.The Roof Tin Making Machine is equipped with the latest features and functionalities to ensure precision and consistency in the production of roof tins. Its automated operation minimizes the risk of human error, resulting in high-quality end products that meet industry standards. Additionally, the machine is built to be durable and long-lasting, making it a valuable asset for any manufacturing facility.One of the most notable features of the Roof Tin Making Machine is its versatility. It is capable of producing a wide range of roof tin profiles, allowing businesses to cater to diverse customer needs without the need for multiple machines. This flexibility not only saves space but also reduces the initial investment required for setting up a production line.Furthermore, the Roof Tin Making Machine is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels. This ensures that businesses can maximize the potential of the machine without the need for extensive training or specialized expertise.In addition to its impressive technical capabilities, (Company Name) understands the importance of providing exceptional customer support. The company's team of experienced professionals is dedicated to assisting clients every step of the way, from the initial inquiry to after-sales service. This commitment to customer satisfaction sets (Company Name) apart from its competitors and has earned it a reputation for reliability and trustworthiness.The introduction of the Roof Tin Making Machine marks a significant milestone for (Company Name) and the manufacturing industry as a whole. As the demand for roofing materials continues to grow, businesses are constantly seeking ways to improve their production processes and stay ahead of the competition. The Roof Tin Making Machine offers a solution that not only meets but exceeds these expectations, setting a new standard for efficiency and quality in roof tin manufacturing.Looking ahead, (Company Name) remains dedicated to pushing the boundaries of innovation and delivering cutting-edge solutions to its clients. With its unwavering commitment to excellence, the company is poised to continue making a positive impact on the manufacturing industry and beyond.In conclusion, the Roof Tin Making Machine represents a game-changing innovation for the manufacturing industry. Its advanced capabilities, combined with (Company Name)'s commitment to customer satisfaction, make it a valuable asset for businesses looking to elevate their production processes. As the demand for high-quality roofing materials continues to increase, the Roof Tin Making Machine is poised to revolutionize the way roof tins are manufactured, setting new standards for efficiency, quality, and reliability.

High-Quality Portable Roll Forming Machine for Sale

Portable Roll Forming Machine Provides Efficient Solution for On-site Metal Fabrication[Company Name], a leading provider of innovative metal forming solutions, has introduced a state-of-the-art portable roll forming machine that is designed to revolutionize on-site metal fabrication processes. This cutting-edge machine offers unparalleled flexibility and efficiency, allowing contractors and builders to streamline their operations and achieve superior results in metal roofing, siding, and other construction applications.The portable roll forming machine is the latest addition to [Company Name]'s comprehensive lineup of metal forming equipment, and it is set to redefine the way metal products are fabricated in the field. With its advanced technology and user-friendly design, this machine enables operators to produce custom metal profiles directly at the job site, eliminating the need for transportation and reducing material waste. This not only saves time and money, but also minimizes the environmental impact of metal fabrication processes.One of the key advantages of the portable roll forming machine is its ability to handle a wide variety of metal materials, including steel, aluminum, and copper. This versatility allows contractors to take on a diverse range of projects without the need for multiple machines, making it an invaluable asset for construction firms of all sizes. In addition, the machine's compact size and lightweight construction make it easy to transport and set up, further enhancing its appeal for on-site fabrication applications.In terms of performance, the portable roll forming machine is engineered to deliver exceptional accuracy and consistency in metal profiling. Its precision roller system and automated controls ensure that each profile meets the exact specifications, resulting in high-quality finished products that meet or exceed industry standards. Furthermore, the machine's adjustable speed and feed settings enable operators to optimize production efficiency and adapt to different material thicknesses with ease.To support users in maximizing the capabilities of the portable roll forming machine, [Company Name] provides comprehensive training and technical support services. Their team of experienced metal forming specialists is on hand to offer guidance on machine setup, operation, and maintenance, ensuring that customers can make the most of their investment and achieve superior results in their metal fabrication projects. This commitment to customer satisfaction is a cornerstone of [Company Name]'s business philosophy, and it has helped them build a reputation as a trusted partner in the metal forming industry."We are thrilled to introduce our portable roll forming machine to the market, as we believe it represents a major breakthrough in on-site metal fabrication technology," said [Spokesperson Name], the CEO of [Company Name]. "This machine is the result of years of research and development, and we are confident that it will empower our customers to take their metal forming capabilities to the next level. From its portable design to its advanced performance features, every aspect of this machine has been engineered with the needs of on-site fabricators in mind."With the introduction of the portable roll forming machine, [Company Name] is poised to set a new standard for on-site metal fabrication efficiency and quality. As construction and renovation projects continue to demand faster turnaround times and superior craftsmanship, this innovative machine is expected to become an indispensable tool for contractors, builders, and metal fabricators seeking to stay ahead of the curve in the industry. [Company Name] remains committed to driving the advancement of metal forming technology, and their portable roll forming machine is a testament to their dedication to innovation and excellence.

High-quality Metal Roof Tile Making Machine for Sale - Find Out More!

[Company Introduction]Based in [Location], [Company Name] is a leading manufacturer and supplier of high-quality metal roof tile making machines. With years of experience in the industry, the company has established a strong reputation for delivering innovative and reliable equipment to its customers around the world. The company prides itself on its commitment to providing cutting-edge technology and exceptional customer service, making it a trusted partner for businesses in the roofing industry.[News Content]Metal Roof Tile Making Machine Revolutionizes Roofing IndustryIn the fast-paced world of construction and building materials, innovation is key to staying competitive. With the demand for durable, eco-friendly, and aesthetically pleasing roofing solutions on the rise, companies are constantly seeking advanced technologies to meet these requirements. One company that has been at the forefront of this innovation is [Company Name], which has recently introduced its latest metal roof tile making machine, revolutionizing the roofing industry.The new metal roof tile making machine from [Company Name] boasts an impressive set of features that sets it apart from traditional machines. The advanced technology and precision engineering behind the machine ensure that it can produce high-quality metal roof tiles with unparalleled efficiency and accuracy. This level of performance not only meets the needs of modern roofing projects but also exceeds industry standards, making it a game-changer for businesses in the roofing sector.One of the key highlights of the machine is its versatility. It is capable of producing a wide range of metal roof tile profiles, allowing for customization and flexibility to meet the specific requirements of different roofing projects. This flexibility is a significant advantage for roofing contractors, as it enables them to cater to diverse customer demands without the need for multiple machines or extensive retooling.Furthermore, the machine is designed for ease of use and maintenance, making it an ideal solution for businesses of all sizes. With user-friendly controls and a robust construction, operators can expect efficient production processes and minimal downtime, ultimately leading to increased productivity and profitability.The introduction of this cutting-edge metal roof tile making machine is a testament to [Company Name]'s commitment to innovation and customer satisfaction. By continuously investing in research and development, the company has been able to deliver advanced solutions that address the evolving needs of the roofing industry. This dedication to excellence has earned [Company Name] a reputation as a trusted partner for businesses looking to elevate their roofing capabilities.In addition to the machine's technical prowess, [Company Name] has also ensured that it aligns with environmentally friendly practices. The machine has been designed to minimize waste and energy consumption, contributing to sustainable manufacturing processes. As sustainability becomes an increasingly important consideration for businesses and consumers alike, this feature further enhances the appeal of the metal roof tile making machine.With the unveiling of this state-of-the-art metal roof tile making machine, [Company Name] has set a new standard for the roofing industry. Its technological advancements, versatility, and sustainability features position it as a game-changing solution for businesses looking to stay ahead in a competitive market.As the demand for high-quality metal roof tiles continues to grow, [Company Name] remains committed to supporting its customers with innovative equipment that not only meets but exceeds their expectations. The new metal roof tile making machine is a reflection of this dedication, and it is poised to make a significant impact on the roofing industry, driving efficiency, quality, and sustainability for years to come.

High-Speed Corrugated Roll Forming Machine with Hydraulic Cutting - Ideal for 914mm and 1220mm Coil Width

Corrugated Sheet Forming Machine: A Revolutionary Solution for Modern BuildingBuilding construction is a vital industry that contributes significantly to the economy. Architects, builders, and property owners strive to create structures that are resilient and aesthetically appealing. However, the process requires heavy investment, and it's vital to use the best materials and tools. One crucial material is the corrugated sheet, which has become popular due to its durability, cost-effectiveness, and versatility. This is where the Corrugated Sheet Forming Machine comes in.The Corrugated Sheet Forming Machine is an innovative solution that has revolutionized the modern building industry. It is a machine designed to transform flat metal sheets into corrugated sheets, which are widely used for roofing, siding, and cladding applications. The machine uses a series of roller dies to create the corrugated profile, which can be customized to different shapes and sizes. It is a fast, efficient, and highly accurate way to produce high-quality corrugated sheets.One of the most important features of the Corrugated Sheet Forming Machine is its motorized cutting and fast drive system. This system allows for quick and easy processing of metal sheets, reducing the time and effort required to create corrugated sheets. Additionally, the hydraulic cutting system ensures precise cutting and minimal waste, further enhancing the machine's efficiency. The machine's 836 type, lengthened design, and 1220 mm coil width make it suitable for producing large volumes of sheets, making it ideal for commercial applications.The Corrugated Sheet Forming Machine is also highly customizable, allowing operators to create different corrugated profiles. This flexibility allows architects and builders to create unique designs that match their clients' preferences. The machine's versatility is further improved by its ability to process different metals, including galvanized steel, aluminum, and copper. This means that users can choose the material that best fits their project requirements, depending on factors such as durability, cost, and aesthetics.In conclusion, the Corrugated Sheet Forming Machine is an essential tool for the modern building industry. Its speed, accuracy, and versatility make it ideal for producing high-quality corrugated sheets for various applications. Whether you are constructing a commercial building, a residential house, or a metal structure, this machine can help you achieve your goals. If you are looking for a reliable and cost-effective way to produce corrugated sheets, the Corrugated Sheet Forming Machine is the perfect solution.

Metal Deck Forming Machine for Floor Construction

We are pleased to announce that {} has recently launched a new Floor Metal Deck Forming Machine that is set to revolutionize the construction industry. This innovative machine is designed to significantly increase the efficiency and quality of floor metal deck forming, making it an essential tool for construction companies and contractors.The Floor Metal Deck Forming Machine is equipped with advanced technology and features that allow for precise and quick metal deck forming. It is capable of handling various types of metal materials, including steel and aluminum, and can produce different profiles and sizes to meet the specific needs of each project. This versatility makes it a valuable asset for construction companies working on a wide range of projects.One of the key highlights of this machine is its ability to automate the metal deck forming process, minimizing the need for manual labor and reducing the risk of errors. This not only saves time and labor costs but also ensures consistent and high-quality results. With the Floor Metal Deck Forming Machine, construction companies can expect to complete their projects more efficiently and with superior structural integrity.In addition to its cutting-edge technology, the Floor Metal Deck Forming Machine is also designed with user-friendliness in mind. Its intuitive interface and controls make it easy for operators to set up and operate the machine, allowing for seamless integration into existing workflows. This ensures that construction companies can quickly adapt to using the machine without significant downtime or disruption.We spoke with the spokesperson for {} to learn more about their vision for the Floor Metal Deck Forming Machine and how it aligns with their commitment to driving innovation in the construction industry. They shared, "At {}, we are constantly striving to develop solutions that address the evolving needs of the construction sector. The Floor Metal Deck Forming Machine is a testament to our dedication to providing cutting-edge equipment that enhances productivity and quality in construction projects."They added, "We understand the challenges that construction companies face when it comes to floor metal deck forming, and we believe that our machine will be a game-changer in addressing these challenges. By streamlining the forming process and delivering consistent, high-quality results, we aim to empower construction companies to take on more complex projects with confidence."The launch of the Floor Metal Deck Forming Machine comes at a time when the construction industry is experiencing a growing demand for efficient and reliable equipment. As construction projects become more complex and timelines more stringent, there is a greater need for innovative tools that can optimize processes and deliver superior outcomes. The Floor Metal Deck Forming Machine is poised to meet these needs and set a new standard for floor metal deck forming in the industry.With its exceptional capabilities and user-friendly design, the Floor Metal Deck Forming Machine is set to become an indispensable asset for construction companies looking to stay ahead of the curve. Its potential to streamline operations, improve efficiency, and elevate the quality of construction projects makes it a must-have for any company looking to take their floor metal deck forming to the next level.In conclusion, the launch of the Floor Metal Deck Forming Machine signifies a significant advancement in the construction industry, thanks to the innovative approach and commitment to excellence that {} brings to the table. As construction companies prepare for the next era of building projects, this machine promises to be a cornerstone in their pursuit of greater efficiency, productivity, and quality.

High-Quality Horizontal Profiled Panel Roll Forming Equipment for Efficient Production

In recent years, the construction industry has seen significant advancements in technology and machinery, leading to more efficient and cost-effective methods of production. One such advancement is the development of Horizontal Profiled Panel Roll Forming Equipment, which has revolutionized the way in which metal panels are manufactured for use in various construction projects. One of the leading companies at the forefront of this innovation is [Company Name]. With a strong focus on research and development, [Company Name] has been able to create state-of-the-art roll forming equipment that has significantly improved the production process for horizontal profiled panels.The Horizontal Profiled Panel Roll Forming Equipment developed by [Company Name] is designed to efficiently produce consistent and high-quality metal panels with minimal manual labor. This has not only increased the speed of production but has also resulted in cost savings for companies utilizing this technology. In addition, the equipment's ability to accurately form complex profiles has opened up new possibilities for architects and designers, allowing for the creation of unique and visually striking building designs. This has sparked a new wave of creativity in the construction industry, as builders and architects are now able to explore more elaborate and intricate designs without being limited by the constraints of traditional manufacturing methods.Furthermore, [Company Name] has ensured that their roll forming equipment is user-friendly and easy to operate, providing comprehensive training and support to their clients. This has allowed construction companies of all sizes to benefit from this advanced technology, further expanding its impact on the industry as a whole.With a commitment to sustainability, [Company Name] has also developed their roll forming equipment with energy efficiency in mind, reducing waste and environmental impact. This aligns with the growing trend of sustainable construction practices and has positioned [Company Name] as a leader in promoting eco-friendly solutions within the industry.As a result of these advancements, [Company Name] has solidified itself as a trusted provider of Horizontal Profiled Panel Roll Forming Equipment, gaining recognition for its reliability, efficiency, and high-quality output. The company's dedication to continuous improvement and innovation has set a new standard for the industry and has inspired others to follow suit.Looking ahead, [Company Name] is committed to further advancing its roll forming technology, with a focus on enhancing automation, expanding production capabilities, and exploring new materials. By staying at the forefront of these developments, [Company Name] is poised to continue driving progress and innovation within the construction industry.In conclusion, Horizontal Profiled Panel Roll Forming Equipment has undoubtedly had a profound impact on the construction industry, offering a more efficient, cost-effective, and sustainable solution for producing metal panels. With [Company Name] leading the way in this field, the future looks bright for the continued advancement of roll forming technology and its contribution to the evolution of modern construction practices.

High-Quality Sheet Making Machine for Ibr Sheets: A Complete Guide

Ibr Sheet Making Machine Company Introduces Latest Innovation in Sheet ManufacturingThe sheet metal industry has seen significant advancements in recent years, with the introduction of new and innovative technologies that have revolutionized the way sheets are manufactured. One company at the forefront of this revolution is ***, a leading manufacturer of sheet making machines. The company has recently introduced its latest innovation in the form of the Ibr Sheet Making Machine, which promises to improve the efficiency and quality of sheet production.The Ibr Sheet Making Machine is designed to cater to the growing demand for high-quality, durable sheets that are used in a wide range of applications, including roofing, construction, and industrial manufacturing. The machine is capable of producing sheets with a range of thicknesses and profiles, allowing for greater flexibility in meeting the specific needs of customers. With its advanced technology and precision engineering, the machine is able to produce sheets that are not only of superior quality but also highly resistant to corrosion and wear.In addition to its cutting-edge technology, the Ibr Sheet Making Machine also offers a number of features aimed at improving efficiency and reducing waste. The machine is equipped with automated controls and sensors that monitor the production process in real-time, making adjustments to ensure consistent quality and minimizing material wastage. This level of automation not only improves the overall efficiency of the production process but also reduces the need for human intervention, thereby reducing the risk of errors and improving workplace safety.Furthermore, ***, the company behind the Ibr Sheet Making Machine, has a long-standing reputation for delivering high-quality, reliable machines to its customers. With a strong focus on research and development, the company has continued to push the boundaries of what is possible in sheet manufacturing, resulting in a range of products that are highly sought after in the industry. The introduction of the Ibr Sheet Making Machine is just the latest example of the company's commitment to innovation and excellence."We are proud to introduce our latest innovation in sheet manufacturing with the launch of the Ibr Sheet Making Machine," said a spokesperson for ***. "This machine represents the culmination of years of research and development, and we believe it will significantly raise the bar for sheet production in the industry. With its advanced technology and efficiency, we are confident that the machine will deliver exceptional results for our customers."The introduction of the Ibr Sheet Making Machine comes at a time when the demand for high-quality sheets is on the rise, driven by the growth of industries such as construction, infrastructure development, and manufacturing. With its ability to produce superior quality sheets in a highly efficient manner, the machine is poised to make a significant impact in the market, providing customers with a reliable and cost-effective solution for their sheet manufacturing needs.As the sheet metal industry continues to evolve, companies like *** are playing a crucial role in driving innovation and pushing the boundaries of what is possible in sheet manufacturing. With the introduction of the Ibr Sheet Making Machine, *** has once again demonstrated its commitment to delivering cutting-edge solutions that meet the needs of the industry and its customers. As the machine begins to make its mark in the market, it is expected to set a new standard for sheet manufacturing, further solidifying ***'s position as a leader in the industry.

How to Choose a Reliable Glazed Tile Corrugation Machine for Color Steel Roofing Projects

Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes the Roofing Industry[date][City], [State] - [Company Name], a leading provider of advanced manufacturing solutions, has introduced a groundbreaking Color Steel Glazed Tile Corrugation Machine that is set to revolutionize the roofing industry. This cutting-edge technology is poised to transform the way roofing materials are produced, offering numerous benefits in terms of efficiency, durability, and aesthetics.The Color Steel Glazed Tile Corrugation Machine, designed and developed by [Company Name], incorporates state-of-the-art features that not only enhance productivity but also improve the overall quality of glazed tile roof panels. The machine is capable of producing perfectly corrugated tiles with a smooth surface finish, offering unmatched visual appeal and longevity to any building structure.One of the key advantages of the Color Steel Glazed Tile Corrugation Machine is its high efficiency. With advanced automation and precision engineering, this machine drastically reduces the time and effort required for tile production. This translates into higher output levels for manufacturers, enabling them to fulfill the growing demands of the market in a shorter span of time.Furthermore, the machine's ability to produce uniform and precise corrugated tiles ensures consistent quality throughout the manufacturing process. This consistency contributes to the overall durability of the finished roofing material, making it highly resistant to wear and tear, extreme weather conditions, and other external factors. The Color Steel Glazed Tile Corrugation Machine is built to last, providing long-lasting protection and aesthetic appeal to buildings.In addition to improving efficiency and durability, this innovative machine also offers enhanced aesthetic options. With a wide range of customizable features, manufacturers can now produce glazed tile roofs in various colors, patterns, and designs. This flexibility caters to diverse architectural needs and allows builders to create visually striking structures.The Color Steel Glazed Tile Corrugation Machine is equipped with advanced technology that facilitates quick and easy set-up, operation, and maintenance. Its user-friendly interface and intuitive controls ensure seamless integration into existing manufacturing processes and minimize downtime. This feature proves invaluable to manufacturers, who can now achieve optimal production levels without investing substantial time and resources into training employees.Moreover, [Company Name] stands out as an industry leader due to its commitment to sustainability. The Color Steel Glazed Tile Corrugation Machine is designed with eco-friendly measures, reducing waste generation, and optimizing energy efficiency. By adopting this machine, manufacturers can contribute to a greener future, aligning their operations with the global sustainability agenda.The introduction of the Color Steel Glazed Tile Corrugation Machine by [Company Name] marks a significant milestone in the roofing industry. Its cutting-edge features, including increased efficiency, enhanced durability, and improved aesthetics, provide manufacturers with a competitive edge. This machine is slated to reshape the roofing materials market and redefine industry standards.With its commitment to innovation, quality, and sustainability, [Company Name] continues to lead the way in the manufacturing sector. The Color Steel Glazed Tile Corrugation Machine is a testament to their dedication to developing advanced solutions that improve efficiency, durability, and aesthetics in roofing production.As the roofing industry embraces this revolutionary technology, buildings worldwide are set to benefit from the exceptional performance and appeal of glazed tile roofs. With the Color Steel Glazed Tile Corrugation Machine, [Company Name] has paved the way for a new era of excellence in the roofing industry.

V-slot Extrusion Aluminum Router/Spindle Mount for CNC Milling Machine Tool Parts M75455850120 [M75455850120] - Affordable and Versatile

Title: Enhance Your CNC Milling Experience with V-Slot Extrusion Aluminum Router/Spindle MountIntroduction:When it comes to CNC milling machines, having the right tool parts and accessories is crucial for maximizing efficiency and precision. One such essential component is the V-Slot Extrusion aluminum router/spindle mount, designed specifically for Makita/Dewalt 611/DW660/Colt OX CNC milling machines. This versatile mount offers incredible stability and durability for milling aluminum extrusions. In this blog, we will explore the benefits of this tool part and how it can revolutionize your CNC machining process.1. Superior Stability and Rigidity:The V-Slot Extrusion aluminum router/spindle mount excels in providing exceptional stability and rigidity during milling operations. Precision engineered with premium quality aluminum, this mount offers robust support to your router or spindle, reducing vibrations and ensuring accurate cuts. The V-slot design further enhances stability by securely anchoring the mount to the machine frame, minimizing unwanted movement during the milling process.2. Compatibility with Popular CNC Milling Machines:Designed with versatility in mind, this mount is compatible with major CNC milling machines such as Makita, Dewalt, DW660, and Colt OX. This widens the scope of applications, allowing users to choose their preferred milling machine without compromising on performance. Whether you are a professional or a DIY enthusiast, having a mount that fits your chosen milling machine is crucial for achieving the desired results.3. Optimal Heat Dissipation:The V-Slot Extrusion mount incorporates advanced heat dissipation features, ensuring efficient cooling during prolonged milling operations. Milling aluminum extrusions can generate significant heat, which may affect the performance and lifespan of the router or spindle. With its innovative design and aluminum construction, this mount effectively dissipates heat, promoting longevity for your machine and maintaining consistent milling accuracy.4. Easy Installation and Adjustment:Installing and adjusting the V-Slot Extrusion mount is a hassle-free process. Thanks to its intuitive design, attaching it to your CNC milling machine requires minimal effort. The mount's versatility allows for quick and precise adjustments, ensuring optimal alignment of the router or spindle. This user-friendly feature is particularly beneficial for users who frequently change router bits or require precise depth adjustments during milling operations.5. Longevity and Durability:The V-Slot Extrusion aluminum router/spindle mount is engineered to withstand the demands of CNC milling operations. Crafted from high-quality aluminum, it offers exceptional durability, withstanding the rigors of daily use in both professional and personal CNC machining settings. Its longevity ensures that you can rely on this tool part for years to come, providing you with consistent performance and precision.Conclusion:Investing in a high-quality V-Slot Extrusion aluminum router/spindle mount for your CNC milling machine is a game-changer that can transform your aluminum extrusion milling experience. The stability, compatibility, heat dissipation, easy installation, and durability offered by this mount make it an excellent addition to any CNC machining setup.So, if you are looking to optimize your CNC machining capabilities, consider upgrading to the V-Slot Extrusion aluminum router/spindle mount. Experience the enhanced stability, precision, and longevity it offers, enabling you to achieve remarkable results in your CNC milling endeavors.Keywords: CNC machine, aluminum extrusions, V-Slot Extrusion mount, router/spindle mount, Makita, Dewalt, DW660, Colt OX, stability, heat dissipation, durability, CNC milling operations.

Get a Comprehensive Roll Forming Solution for Diverse Applications in China

Roll forming machines are extensively used across different industries, and their applications can range from simple tasks to complex product specifications. With the demand for high-quality products and efficient production processes, roll forming machine manufacturers are constantly innovating and designing advanced equipment that can meet the needs of various industries. In China, MTC is a leading roll forming machine manufacturer, providing a one-stop solution from consultation to final training for many different applications where a roll forming machine can do its best.One of the applications where roll forming machines are in high demand is the light steel forming industry. Light steel forming machines are specialized equipment that is designed to form and shape light gauge steel profiles. These machines can handle materials with thicknesses ranging from 0.3mm to 2mm, making them ideal for creating lightweight and strong steel structures. The versatility of light steel forming machines has made them an attractive choice for various industries such as construction, automotive, and furniture.As a prominent roll forming machine manufacturer in China, MTC offers a wide range of light steel forming machines that feature advanced technology and precision engineering. Their equipment is designed to meet the highest quality and safety standards, making them a reliable and long-term investment for businesses.Some of the notable features of MTC’s light steel forming machines include:1. High-precision Roll-forming Process - MTC uses advanced technology and precision engineering to ensure that their light steel forming machines produce high-quality products with tight tolerances. This helps to reduce wastage and improve the efficiency of the production process.2. Modular Design - MTC’s light steel forming machines feature a modular design, which allows for easy customization and integration with existing production equipment. This makes it easier for businesses to adapt to changing market demands and product specifications.3. Flexible Material Support - MTC’s light steel forming machines are designed to work with a wide range of materials, including galvanized steel, stainless steel, aluminum, and other alloys. This versatility helps businesses to cater to a wide range of customer requirements.4. Easy-to-Use Control System - MTC’s light steel forming machines come equipped with an easy-to-use control system that enables operators to adjust and monitor parameters such as speed, size, and thickness. This helps to streamline the production process and reduces the likelihood of errors.In addition to the above features, MTC also provides comprehensive consultation services and training to clients. This ensures that their clients can make informed decisions regarding the choice of equipment and utilize the machines to their full potential. MTC’s after-sales support is also noteworthy, with a dedicated customer support team available to assist businesses with any issues that may arise.In conclusion, MTC is a reliable and experienced roll forming machine manufacturer in China, providing a one-stop solution for businesses looking to invest in light steel forming machines. With their advanced technology and precision engineering, MTC’s light steel forming machines are among the best in the market, offering businesses improved efficiency, better quality control, and enhanced flexibility. If you are in the market for a light steel forming machine, choose MTC for quality and value.