The Process of Slitting Line: A Complete Guide

By:Admin

Industry Leader in Slitting Line Process

With a commitment to innovation and excellence, {Company Name} is leading the way in the slitting line process industry. The company has a proven track record of providing high-quality slitting line solutions to a wide range of industries, including automotive, construction, and appliance manufacturing. With state-of-the-art technology and a team of experienced professionals, {Company Name} is dedicated to meeting the unique needs of each customer with precision and efficiency.

The slitting line process is a critical step in the manufacturing of various metal products. It involves cutting large coils of metal into narrower coils of the desired width, ensuring uniformity and accuracy in the final product. This process requires advanced machinery and expertise to achieve optimal results, and that's where {Company Name} excels.

{Company Name} offers a comprehensive range of slitting line solutions, including but not limited to decoiling, slitting, and recoiling. Their advanced slitting line machinery is designed to handle a variety of materials, such as stainless steel, aluminum, and galvanized steel, with precision and speed. Whether it's for high-volume production or custom requirements, {Company Name} provides tailored solutions to meet the specific needs of their customers.

In addition to their cutting-edge machinery, {Company Name} places a strong emphasis on customer satisfaction. Their team of professionals works closely with clients to understand their unique requirements and provide customized solutions that ensure the highest quality end product. With a focus on efficiency and productivity, {Company Name} helps their customers optimize their operations and achieve a competitive edge in the market.

The company's commitment to excellence is reflected in their continuous investment in research and development. {Company Name} is dedicated to staying at the forefront of technological advancements in the slitting line process, ensuring that their customers have access to the most advanced solutions available. By leveraging the latest innovations, {Company Name} is able to provide reliable, cost-effective, and sustainable slitting line solutions that meet the evolving needs of the industry.

With a global footprint, {Company Name} serves customers around the world, delivering high-quality slitting line solutions that adhere to the highest standards of quality and performance. Whether it's for large-scale industrial operations or smaller-scale businesses, {Company Name} is committed to being a trusted partner that delivers exceptional value to their clients.

In summary, {Company Name} is a leading provider of slitting line solutions, offering cutting-edge technology, personalized service, and a commitment to excellence. With a focus on innovation and customer satisfaction, {Company Name} continues to set the benchmark for the slitting line process industry, helping their clients achieve success in their respective markets.

For more information on {Company Name} and their slitting line solutions, please visit their website at www.companyname.com.

Company News & Blog

China's Leading Manufacturer Offers Comprehensive Roll Forming Solutions for Various Applications

Roofing Sheet Forming Machine: The Ultimate Solution for Precise and Efficient RoofingWhen it comes to roofing materials, choosing the right one is crucial to ensure the durability and aesthetics of a building. Among the various options available, roofing sheets have become increasingly popular due to their versatility and cost-effectiveness. However, to efficiently produce roofing sheets that meet specific requirements, a reliable and precise manufacturing process is essential. That's where a Roofing Sheet Forming Machine comes into play.A roofing sheet forming machine is an advanced piece of equipment designed specifically for the production of roofing sheets. It is widely used across various industries, including construction, architecture, and manufacturing. The machine utilizes the process of roll forming, which is known for its accuracy and efficiency in creating uniform and high-quality products.The roll forming process involves passing a sheet of metal through a series of rollers, gradually shaping it into the desired profile. With the use of custom-made molds, the machine can produce different types of roofing sheets, such as corrugated, trapezoidal, and standing seam profiles. This flexibility allows manufacturers to cater to a wide range of customer demands and project specifications.One of the significant advantages of using a Roofing Sheet Forming Machine is its ability to ensure precision and consistency throughout the production process. Each roller in the machine is uniquely designed to shape the metal sheet with precise measurements and dimensions. This results in roofing sheets that fit perfectly and are aesthetically pleasing.Additionally, the machine's high-speed operation enables manufacturers to produce a large volume of roofing sheets quickly. This not only saves time but also enhances productivity, making it an ideal choice for mass production. Furthermore, the machine's automated control system eliminates the need for manual labor, reducing the chances of errors and ensuring a safer working environment.Quality is of utmost importance when it comes to roofing materials, and a Roofing Sheet Forming Machine excels in delivering consistent and durable products. By using high-quality materials and advanced manufacturing techniques, these machines guarantee the production of roofing sheets that are resistant to corrosion, weathering, and wear. This durability ensures that the roofs constructed using these sheets can withstand harsh environmental conditions and provide long-lasting protection.In addition to its primary function of manufacturing roofing sheets, a Roofing Sheet Forming Machine offers several other benefits. It provides versatility by offering customizability options, allowing manufacturers to produce roofing profiles of different lengths, widths, and thicknesses. This ensures that they can cater to diverse customer requirements and project specifications.Moreover, the machine's operation is accompanied by minimal noise and vibration, thanks to its advanced engineering and quality construction. This reduces disturbances in the workplace and contributes to a peaceful working environment for employees. Additionally, the machine requires minimal maintenance, leading to lower operational costs and improved overall efficiency.As the demand for roofing sheets continues to rise, it is essential to choose a reliable and experienced manufacturer when investing in a Roofing Sheet Forming Machine. A reputable manufacturer will not only provide top-quality machines but also offer comprehensive support and service throughout the purchase process. They will assist in the selection of the right machine, provide installation and training, and offer after-sales support to ensure smooth and efficient operations.In conclusion, a Roofing Sheet Forming Machine is the ultimate solution for producing precise, durable, and cost-effective roofing sheets. Its ability to deliver consistent quality, high-speed production, and customizability makes it an indispensable piece of equipment in the roofing industry. So, whether you are a contractor, builder, or manufacturer, investing in a Roofing Sheet Forming Machine is a wise choice to elevate your roofing business to new heights.

High-Quality Storage Rack Roll Forming Machine for Efficient Warehouse Organization

Storage Rack Roll Forming Machine Revolutionizes Storage SolutionsIn today's fast-paced world, the demand for efficient and cost-effective storage solutions is higher than ever. The industrial sector, in particular, is constantly seeking innovative technologies to optimize their storage processes. This is where the innovative Storage Rack Roll Forming Machine, from {}, comes into play. This revolutionary machine has the potential to transform the way storage racks are fabricated, providing a quicker, more efficient, and more cost-effective solution for businesses around the world.{}, the company behind this cutting-edge technology, is a leading manufacturer of roll forming machines. With over 20 years of experience in the industry, they have consistently delivered high-quality, reliable, and efficient roll forming solutions to their global clientele. Their commitment to innovation, product quality, and customer satisfaction has positioned them as a trusted and respected name in the roll forming machinery industry.The Storage Rack Roll Forming Machine, developed by {}, is a state-of-the-art piece of equipment designed to fabricate storage racks with unparalleled precision and efficiency. This machine is capable of producing storage racks of various sizes and configurations, catering to the diverse needs of industries such as logistics, warehousing, manufacturing, and retail.One of the key features of the Storage Rack Roll Forming Machine is its flexibility. The machine can be easily adjusted to accommodate different types of materials, including steel, aluminum, and other alloys. This flexibility allows businesses to customize their storage racks according to their specific requirements, without the need for additional machinery or extensive retooling.Furthermore, the Storage Rack Roll Forming Machine is equipped with advanced automation and control systems, enabling seamless operation and minimizing the risk of errors or defects in the final product. This not only improves the overall production efficiency but also ensures the consistency and quality of the storage racks being manufactured.In addition to its technical capabilities, the Storage Rack Roll Forming Machine is also designed with the operator in mind. The user-friendly interface and intuitive controls make it easy for operators to set up, operate, and maintain the machine, reducing the need for extensive training and minimizing the risk of human error.By implementing the Storage Rack Roll Forming Machine into their production processes, businesses can expect to see a significant increase in productivity and cost savings. The machine's high-speed operation and efficient material utilization translate to shorter lead times and reduced production costs, ultimately leading to improved profitability for the end-user.In a highly competitive market, where efficiency and cost-effectiveness are crucial factors for success, the Storage Rack Roll Forming Machine from {} offers a competitive edge to businesses seeking to streamline their storage rack manufacturing processes. Its ability to deliver consistent, high-quality results in a fast and efficient manner positions it as a game-changer in the industry.With a strong track record of delivering innovative and reliable roll forming solutions, {} is well-equipped to meet the growing demand for the Storage Rack Roll Forming Machine. Their dedication to customer satisfaction and their commitment to excellence make them a trusted partner for businesses looking to enhance their storage solutions.In conclusion, the Storage Rack Roll Forming Machine from {} represents a significant advancement in the field of storage rack manufacturing. Its innovative technology, coupled with {}'s expertise and reputation for excellence, makes it a compelling choice for businesses seeking to optimize their production processes and stay ahead of the competition. As the demand for efficient and cost-effective storage solutions continues to grow, the Storage Rack Roll Forming Machine is poised to make a lasting impact on the industry.

High-Quality Color Steel Roll Forming Machine for GP GI Materials

{Company Name} is a leading manufacturer of roll forming machines, specializing in the production of high-quality and efficient machines to meet the needs of various industries. With a strong focus on innovation and technology, the company has consistently delivered state-of-the-art roll forming machines that have set industry standards.The latest addition to {Company Name}’s impressive lineup of roll forming machines is the GP GI Color Steel Roll Forming Machine. This machine is designed to meet the growing demand for high-quality and durable steel roll forming solutions. With its advanced features and precise engineering, the GP GI Color Steel Roll Forming Machine is set to revolutionize the steel forming industry.One of the key features of the GP GI Color Steel Roll Forming Machine is its ability to produce a wide range of steel profiles with precision and speed. The machine is equipped with advanced roll forming technology that allows for the quick and efficient production of high-quality steel products. This versatility makes the GP GI Color Steel Roll Forming Machine an ideal choice for companies looking to expand their product offerings and meet the diverse needs of their customers.In addition to its impressive production capabilities, the GP GI Color Steel Roll Forming Machine is also designed with user-friendly features that make operation and maintenance simple and efficient. This includes a user-friendly interface, easy-to-access components, and a durable construction that ensures longevity and reliability. With these features, operators can maximize productivity and minimize downtime, leading to greater profitability and customer satisfaction.Another standout feature of the GP GI Color Steel Roll Forming Machine is its ability to produce steel products with superior surface quality and color consistency. This is achieved through the machine's advanced color coating technology, which ensures that the final products have a consistent and vibrant color finish. This is a crucial advantage for companies that require high-quality steel products with a premium aesthetic appeal.Furthermore, the GP GI Color Steel Roll Forming Machine is designed with efficiency and sustainability in mind. The machine is equipped with energy-saving features and operates with minimal waste, making it an environmentally friendly choice for companies looking to reduce their carbon footprint and operating costs.As a trusted leader in the roll forming industry, {Company Name} is committed to providing comprehensive support and service for the GP GI Color Steel Roll Forming Machine. The company offers on-site installation, training, and ongoing technical assistance to ensure that customers can maximize the potential of their investment. This dedication to customer satisfaction and support further solidifies {Company Name}’s reputation as a reliable and value-driven partner in the industry.With the introduction of the GP GI Color Steel Roll Forming Machine, {Company Name} continues to uphold its reputation as a forward-thinking innovator in the roll forming industry. The machine's advanced features, precision engineering, and user-friendly design make it a standout choice for companies looking to elevate their steel forming capabilities and stay ahead of the competition.In conclusion, the GP GI Color Steel Roll Forming Machine from {Company Name} represents a significant advancement in the roll forming industry. With its advanced technology, versatility, and user-friendly design, this machine is set to redefine the standards for steel roll forming, providing companies with a reliable and efficient solution for their production needs. As {Company Name} continues to push the boundaries of innovation, the GP GI Color Steel Roll Forming Machine stands as a testament to the company's commitment to excellence and customer satisfaction.

Ultimate Guide to Horizontal Barrel Vault Panel Bending Machines

The leading manufacturer of sheet metal processing equipment, has recently launched its latest innovation, the Horizontal Barrel Vault Panel Bending Machine. This state-of-the-art machine is designed to meet the growing demand for efficient and precise panel bending in the construction and manufacturing industries.The Horizontal Barrel Vault Panel Bending Machine is a versatile and powerful tool that can handle a wide range of panel bending operations. It is equipped with advanced technology and features that enable it to bend large panels with extreme precision and accuracy. This machine is an ideal choice for fabricating curved panels that are used in various architectural and construction applications.One of the key features of the Horizontal Barrel Vault Panel Bending Machine is its horizontal design, which allows for easy loading and unloading of panels. This design also enables the machine to bend panels in a more efficient and consistent manner, resulting in higher productivity and lower production costs. Additionally, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain.The company has a rich history of providing innovative and reliable sheet metal processing equipment to its customers. With over [number] years of experience in the industry, the company has built a strong reputation for delivering high-quality products and exceptional customer service. The launch of the Horizontal Barrel Vault Panel Bending Machine further demonstrates the company's commitment to meeting the evolving needs of its customers and the industry.In addition to its technical capabilities, the company is also known for its dedication to sustainability and environmental stewardship. The Horizontal Barrel Vault Panel Bending Machine is designed with energy-efficient features that help reduce power consumption and minimize its environmental impact. This commitment to sustainability aligns with the company's larger mission to develop innovative solutions that support a more sustainable and responsible manufacturing industry.The launch of the Horizontal Barrel Vault Panel Bending Machine has already generated significant interest and excitement within the industry. Many leading construction and manufacturing companies have expressed their eagerness to explore the capabilities of this new machine and incorporate it into their operations. The company is confident that the machine will make a positive impact on the industry and help its customers achieve new levels of productivity and efficiency.As the demand for curved panels continues to grow in the construction and architecture sectors, the Horizontal Barrel Vault Panel Bending Machine is expected to play a pivotal role in meeting this demand. Its advanced technology, user-friendly design, and commitment to sustainability make it a standout choice for companies looking to enhance their panel bending capabilities.The company is poised to continue its legacy of innovation and excellence with the launch of the Horizontal Barrel Vault Panel Bending Machine. With its industry-leading expertise and dedication to customer satisfaction, the company is well-positioned to shape the future of sheet metal processing and support the evolving needs of the construction and manufacturing industries.

High-quality Cold Roller Former for Efficient Metal Processing

Cold Roller Former, a cutting-edge technology developed by a leading manufacturing company, is making waves in the industry with its innovative and efficient cold rolling process. This revolutionary machine is designed to shape metallic materials into various components, providing a cost-effective and high-quality solution for a wide range of applications.The cold rolling process is a critical step in metal forming, as it helps to improve the surface finish and mechanical properties of the material. Unlike traditional hot rolling, cold rolling occurs at room temperature, which results in a smoother and more precise finish. This method is particularly important for industries such as automotive, aerospace, and construction, where the quality and integrity of the metal components are paramount.With the introduction of Cold Roller Former, manufacturers can now benefit from a streamlined and advanced cold rolling process. This machine is equipped with state-of-the-art technology, including precision control systems and high-speed capabilities, allowing for the efficient production of complex and high-quality components. Additionally, its modular design and customizable features make it adaptable to various production needs, providing flexibility and versatility to manufacturers.One of the key advantages of Cold Roller Former is its ability to produce parts with tighter tolerances and improved surface finish, resulting in higher precision and quality. This is particularly beneficial for industries that require components with intricate geometries and superior mechanical properties. With Cold Roller Former, manufacturers can achieve a level of consistency and accuracy that is not possible with traditional cold rolling methods, leading to enhanced product performance and reliability.Furthermore, Cold Roller Former is designed with efficiency in mind, offering a significant increase in productivity and cost savings for manufacturers. Its high-speed capabilities and advanced control systems enable faster production cycles and reduced material waste, resulting in a more streamlined and economical manufacturing process. This not only helps to improve the overall competitiveness of manufacturers but also contributes to a more sustainable and environmentally friendly production environment.In addition to its technological advancements, Cold Roller Former is backed by a dedicated team of experts who provide comprehensive support and expertise to ensure the successful implementation and operation of the machine. From initial consultation to ongoing maintenance and training, the company's commitment to customer satisfaction and knowledge sharing sets a new standard for excellence in the industry.As a testament to its success, Cold Roller Former has already made significant strides in the market, garnering attention and accolades from industry experts and customers alike. Its proven track record of delivering superior performance, cost-effectiveness, and reliability has positioned it as the go-to solution for manufacturers seeking to elevate their cold rolling capabilities.Looking ahead, the company is committed to further advancing and enhancing Cold Roller Former to meet the evolving needs of the industry. With ongoing research and development efforts, the company is dedicated to pushing the boundaries of cold rolling technology, ultimately redefining the standards of excellence and innovation in metal forming.In conclusion, Cold Roller Former represents a significant breakthrough in cold rolling technology, offering a game-changing solution for the manufacturing industry. With its advanced capabilities, efficiency, and reliability, this revolutionary machine is poised to shape the future of cold rolling and set a new benchmark for excellence in metal forming.

High-quality Steel Profile Manufacturing Machine for Your Business Needs

Color Steel Profile Manufacturing Machine, a leading manufacturer of steel profile manufacturing machinery, has announced the launch of a new series of cutting-edge machines that are set to revolutionize the industry.With over 20 years of experience in the industry, Color Steel Profile Manufacturing Machine has built a solid reputation for delivering high-quality, innovative solutions to meet the evolving needs of the steel profile manufacturing sector. The company prides itself on its commitment to excellence, attention to detail, and dedication to customer satisfaction.The new series of machines leverages the latest advancements in technology to offer state-of-the-art features and capabilities. From precision engineering to seamless integration with existing manufacturing processes, these machines are designed to optimize productivity, improve efficiency, and reduce manufacturing costs.One of the key highlights of the new series is its enhanced automation capabilities. These machines are equipped with advanced automation systems that enable seamless operation, minimal human intervention, and improved safety. This not only streamlines the manufacturing process but also reduces the risk of errors and enhances overall product quality.In addition to automation, the new series also boasts advanced control systems that provide real-time monitoring and adjustment of key parameters. This enables operators to fine-tune the machines for optimal performance, resulting in higher yields and better quality products.Furthermore, the new series is engineered for versatility, with the ability to produce a wide range of steel profiles with varying specifications, dimensions, and finishes. This flexibility allows manufacturers to cater to a diverse array of customer requirements and market demands, without the need for multiple machines or extensive retooling.Another notable feature of the new series is its energy-efficient design. With a focus on sustainability and cost-effectiveness, the machines are engineered to minimize energy consumption without compromising performance. This not only benefits the environment but also offers significant cost savings for manufacturers in the long run.Color Steel Profile Manufacturing Machine understands the importance of ongoing support and service, which is why the new series comes with comprehensive training, technical support, and aftersales services. This ensures that customers can maximize the value of their investment and operate the machines with confidence and peace of mind.As the steel profile manufacturing industry continues to evolve and grow, the launch of the new series from Color Steel Profile Manufacturing Machine represents a significant milestone. The company remains committed to pushing the boundaries of innovation and delivering solutions that empower manufacturers to thrive in a competitive market."We are excited to introduce our latest series of steel profile manufacturing machines," said a spokesperson for Color Steel Profile Manufacturing Machine. "With their advanced features and capabilities, we believe these machines will set new standards for performance, efficiency, and reliability. We are confident that they will be a game-changer for manufacturers looking to stay ahead in the industry."The new series of machines from Color Steel Profile Manufacturing Machine is now available for order, with customization options to suit specific requirements. With its track record of excellence and a forward-looking approach to innovation, the company is poised to continue leading the way in the steel profile manufacturing sector.

Advanced Length Cutting Machine for Precision Cuts

Automatic Length Cutting Machine Revolutionizes Manufacturing Process for [Company Name][City, State] - [Company Name], a leading manufacturing company in the [industry] sector, has recently introduced a state-of-the-art Automatic Length Cutting Machine to their production line. This cutting-edge technology has revolutionized the manufacturing process, allowing for more efficient and precise cutting of materials, ultimately enhancing the overall product quality and production output.The Automatic Length Cutting Machine, which is designed and developed in-house by [Company Name] engineers, utilizes the latest automation and software technology to accurately measure, cut, and process various materials such as steel, aluminum, and other metals. The machine is equipped with advanced sensors and controls that ensure precise cutting according to the required specifications, reducing material waste and minimizing human error."We are thrilled to introduce this cutting-edge Automatic Length Cutting Machine to our production line," said [Name], CEO of [Company Name]. "This technology represents a significant advancement in our manufacturing capabilities, allowing us to achieve higher levels of precision and efficiency in our production processes. It also reflects our commitment to innovation and delivering high-quality products to our customers."The implementation of the Automatic Length Cutting Machine has had a profound impact on [Company Name]'s manufacturing operations. With its ability to accurately cut materials to the required length and specifications, the company has experienced a significant reduction in production time and costs. Additionally, the machine's automation capabilities have freed up labor resources, allowing employees to focus on more intricate and value-added tasks within the production process.Furthermore, the precise cutting enabled by the Automatic Length Cutting Machine has resulted in a higher quality end product. This has been well-received by [Company Name]'s customers, who have noted the improvement in the consistency and accuracy of the materials used in their projects.In addition to the technical capabilities of the Automatic Length Cutting Machine, [Company Name] has also focused on the machine's user-friendly interface and easy integration with their existing production systems. This has allowed for a seamless transition and adoption of the new technology within their manufacturing facility."We have been thoroughly impressed with the performance and reliability of the Automatic Length Cutting Machine," said [Name], a production manager at [Company Name]. "The machine's intuitive interface and seamless integration with our existing systems have made the transition smooth, and we have seen tangible improvements in our production efficiency and product quality."Looking ahead, [Company Name] is committed to further enhancing the capabilities of the Automatic Length Cutting Machine, with plans to integrate more advanced features and functionalities in future iterations. The company also aims to explore opportunities to customize the technology to meet the specific needs of different industries and applications, expanding its market reach and potential impact.The introduction of the Automatic Length Cutting Machine has firmly positioned [Company Name] as a pioneer in the industry, setting new standards for manufacturing efficiency and quality. With its focus on innovation and commitment to delivering exceptional products, [Company Name] continues to lead the way in transforming the manufacturing landscape.As [Company Name] looks to the future, the Automatic Length Cutting Machine will undoubtedly play a pivotal role in driving the company's growth and cementing its reputation as a trusted partner for high-quality, precision-engineered products in the [industry] sector.For more information about [Company Name] and its range of products and services, please visit [company website].Contact:[Name][Title][Company Name][Phone Number][Email Address]

How to choose the best smartphone for your needs

[Company Name] Launches New Technology to Revolutionize Data Analysis[City, Date] - [Company Name] has recently announced the launch of their groundbreaking [product name], promising to revolutionize the way data is analyzed and processed. This new technology is set to disrupt the current market, providing faster and more accurate results for businesses and organizations around the world.The [product name] is a sophisticated data analysis tool that utilizes advanced algorithms and machine learning techniques to process and interpret large volumes of data. It is designed to offer businesses a comprehensive and user-friendly platform for all their data analysis needs.[Company Name] is a global leader in innovative technology solutions, specializing in data analytics, artificial intelligence, and machine learning. Their team of experts has been working tirelessly to develop the [product name], which has the potential to transform the way businesses harness and utilize their data.The [product name] is equipped with a range of powerful features, including predictive analytics, data visualization, and real-time monitoring. This allows businesses to gain deeper insights into their data, enabling them to make better informed decisions and drive business growth."We are excited to introduce the [product name] to the market," said [Company Name]'s CEO. "This new technology represents a significant milestone in the field of data analysis, and we believe it has the potential to empower businesses with a deeper understanding of their data."The [product name] also offers seamless integration with existing data management systems, allowing businesses to streamline their data analysis processes and eliminate the need for multiple tools. This will not only save time and resources, but also improve the overall efficiency of data analysis within organizations.In addition to its advanced features, the [product name] is also designed to be user-friendly, with an intuitive interface that enables users to easily navigate and utilize its capabilities. This makes it accessible to a wide range of businesses, regardless of their size or industry.With the launch of the [product name], [Company Name] aims to empower businesses with the tools they need to extract valuable insights from their data, driving innovation and growth. The company is confident that the [product name] will set new industry standards and lead the way in data analysis technology."We believe that the [product name] has the potential to transform the way businesses approach data analysis," added the CEO of [Company Name]. "We are committed to empowering organizations with the insights they need to thrive in today's data-driven world."The [product name] is now available for businesses worldwide, and [Company Name] is offering a range of flexible pricing options to suit the needs of different organizations. Businesses can now experience the power of the [product name] and take their data analysis capabilities to the next level.For more information about the [product name] and [Company Name]'s other innovative solutions, visit their website at [company website]. With their dedication to pushing the boundaries of technology, [Company Name] continues to be at the forefront of innovation in the data analysis industry.

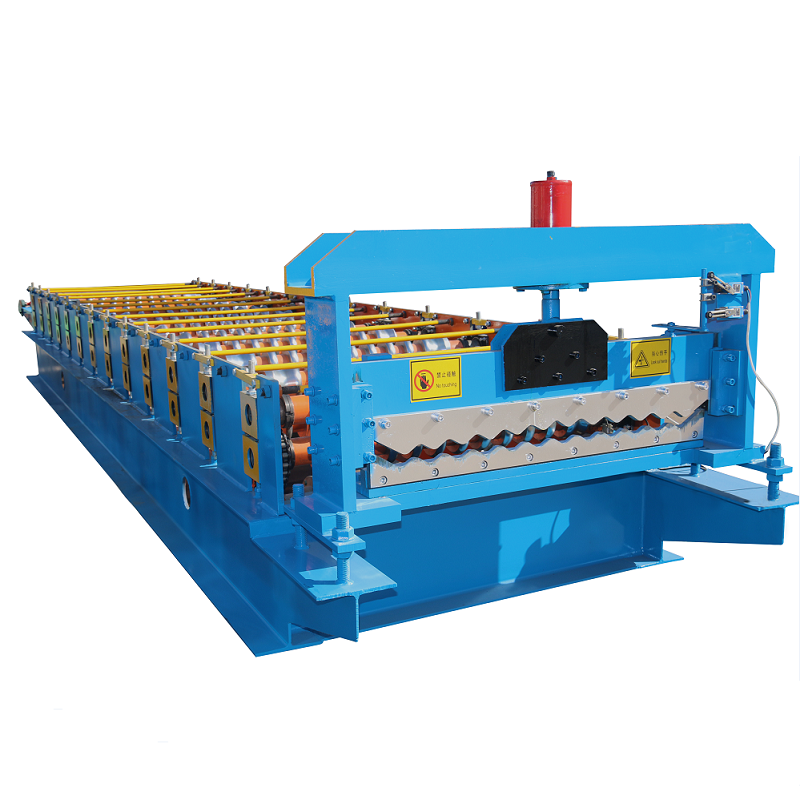

High-Quality Color Steel Sheeting Roofing Panel Cold Roll Forming Machine - Efficient and Easy to Operate This hand-operated rolling machine is an affordable and reliable solution for producing high-quality color steel sheeting roofing panels. It boasts low energy consumption and a yield strength of 32MPa, making it ideal for small-scale production. The equipment includes a roll forming system, hydraulic cutter, hydraulic station, electric control system, counter, and product supporter. With a processing speed of 8m/min and thickness range of 0.3-1mm, this machine is efficient and easy to operate.

, Sheet Hand Operated Rolling Machine, Cold Roll Forming Machine, Roofing Panel Roll Forming Machine, Mechanical Kingdom.Sheet Hand Operated Rolling Machine - A Reliable and Low-Cost Solution for Color Steel Sheeting Roofing Panel ManufacturingThe sheet hand operated rolling machine is a cost-effective and efficient solution for manufacturing color steel sheeting roofing panels. With its reliable working mechanism, easy operation, and low energy consumption, the machine is an excellent choice for small to medium-scale manufacturing units.Certificate and SpecificationsThe sheet hand operated rolling machine adheres to the CE certification and comes with a 7.5 KW main motor power and 4 KW hydraulic station power. The machine's sprocket is P-25.4, with 20 roller station capacity, which can produce a yield strength of up to 32MPa. The diameter of the principal axis is 70mm, and the roller material is made of 45# steel hard chrome plating. The machine can process sheets with a thickness of 0.3-1mm and has an installation dimension of about (L*W*H) 10*1.5*0.8M.Functional Features and AdvantagesThe sheet hand operated rolling machine is designed with several functional features that make it a robust and reliable option for color steel sheeting roofing panel manufacturing. Some notable features include:Low-Cost and High Efficiency: The machine is a low-cost and high-efficiency solution that can complete the manufacturing process quickly and efficiently.Reliable Working Mechanism: The machine's working mechanism is reliable, ensuring that the quality of the products is consistent.Easy Operation: The machine is easy to operate, even for those with no prior experience in the field.Low Energy Consumption: The machine consumes minimal energy, making it an eco-friendly option that reduces the energy bills.Equipment PartsThe machine includes several equipment parts, including roll forming, hydraulic cutter, hydraulic station, electric controlling system, counter, and product supporter. These parts work together to ensure that the machine can produce high-quality color steel sheeting roofing panels.Manufacturers of Roll Forming MachinesMechanical Kingdom is a renowned manufacturer of roll forming machines, operating in this field for the past 12 years. They offer a wide range of products, including tile-crushing computer control systems, ancient glazed tile copy machines, Laura machines, beam-free arch making machines, great-span, and beam-free structure equipment, as well as motor car plate making machines.ConclusionIn conclusion, the sheet hand operated rolling machine is a reliable, low-cost, and efficient solution for color steel sheeting roofing panel manufacturing. With its easy operation, low energy consumption, and robust working mechanism, it is an excellent choice for small to medium-scale manufacturing units. Mechanical Kingdom is a reputable manufacturer of roll forming machines, offering a range of products that cater to various requirements.

How Drip Edge Roll Forming Machines are Advancing Construction Technology

Drip Edge Roll Forming Machine: Innovating the Construction IndustryThe construction industry has seen a significant transformation over the years, and the introduction of advanced machinery has revolutionized the way buildings are constructed. One such innovative piece of equipment is the Drip Edge Roll Forming Machine, which has been making waves in the construction sector. This state-of-the-art machinery is designed to streamline the process of manufacturing drip edge profiles, offering a range of benefits including efficiency, precision, and cost-effectiveness.The Drip Edge Roll Forming Machine is the brainchild of a leading manufacturing company that specializes in producing a wide range of roll forming machinery for various industries. With years of expertise and a strong focus on research and development, the company has established itself as a pioneer in the field of roll forming technology. Their commitment to delivering high-quality, innovative solutions has earned them a stellar reputation among their clients and peers.The Drip Edge Roll Forming Machine is a testament to the company's dedication to continuous improvement and innovation. It is designed to meet the growing demand for high-quality drip edge profiles in the construction industry. The machine features a cutting-edge design that allows for the efficient and precise forming of drip edge profiles, ensuring consistent quality and seamless integration into building structures.One of the key highlights of the Drip Edge Roll Forming Machine is its advanced automation capabilities. The machine is equipped with a user-friendly interface and programmable controls, allowing for easy operation and customization of drip edge profiles. This level of automation not only enhances operational efficiency but also minimizes the risk of errors, resulting in higher productivity and cost savings for construction companies.In addition to its automation features, the Drip Edge Roll Forming Machine is also known for its versatility. It is capable of producing a wide range of drip edge profiles, accommodating various design requirements and specifications. This flexibility makes it an ideal solution for construction projects of all scales, from residential buildings to commercial complexes.Furthermore, the Drip Edge Roll Forming Machine is designed with durability and longevity in mind. It is built using high-quality materials and components, ensuring robustness and reliability even under heavy usage. This durability, combined with the company's excellent after-sales support, provides clients with peace of mind and a solid return on investment.The introduction of the Drip Edge Roll Forming Machine has had a significant impact on the construction industry. It has empowered construction companies to elevate the quality of their buildings while reducing production costs and lead times. By integrating this advanced machinery into their operations, construction firms can stay ahead of the competition and meet the evolving demands of the market.In conclusion, the Drip Edge Roll Forming Machine represents a significant advancement in the construction industry. Its innovative design, advanced automation capabilities, versatility, and durability have set a new standard for manufacturing drip edge profiles. With a strong focus on delivering value and excellence, the company behind this remarkable machinery continues to drive progress in the field of roll forming technology. As the construction sector continues to evolve, the Drip Edge Roll Forming Machine stands as a beacon of innovation, propelling the industry towards a more efficient and sustainable future.