Ultimate Guide to Standing Seam Machines

By:Admin

Established in 1995, our company has been a pioneer in the manufacturing of roofing and construction equipment. Our commitment to quality, innovation, and customer satisfaction has propelled us to the forefront of the industry. With state-of-the-art facilities and a team of highly skilled professionals, we have been able to consistently deliver high-quality products to our clients.

[News Content]

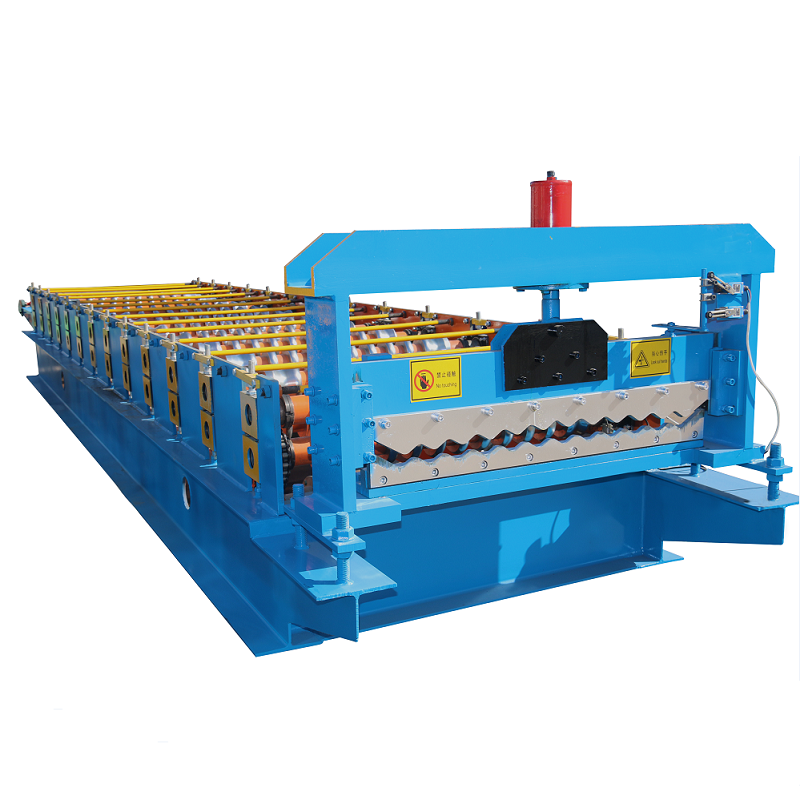

The latest addition to our range of cutting-edge equipment is the Standing Seam Machine. With its innovative design and advanced features, this machine is set to revolutionize the roofing industry. The Standing Seam Machine is a versatile and efficient tool that is capable of producing high-quality standing seam panels for a variety of roofing applications.

One of the key features of the Standing Seam Machine is its ability to produce panels with precision and speed. Equipped with advanced technology, the machine is able to accurately create standing seam panels of varying widths and lengths, all while maintaining a smooth and seamless finish. This level of precision is essential in ensuring the durability and performance of the roofing panels.

Additionally, the Standing Seam Machine is designed for ease of use and convenience. Its user-friendly interface and intuitive controls make it simple for operators to set up and start producing panels quickly and efficiently. This not only saves time and labor costs but also enhances overall productivity.

Furthermore, the Standing Seam Machine is built to withstand the rigors of heavy-duty use. Constructed from high-quality materials, the machine is durable and reliable, able to consistently deliver excellent results even in challenging working environments. This robust construction ensures that the machine will provide years of dependable service to its users.

In addition to its technical capabilities, the Standing Seam Machine is also designed with safety in mind. With built-in safety features and compliance with industry standards, operators can have peace of mind knowing that they can work with the machine safely and securely.

Our company is proud to offer the Standing Seam Machine to our clients, and we are confident that it will meet and exceed their expectations. As with all of our products, the Standing Seam Machine has undergone rigorous testing and quality assurance processes to ensure that it meets our high standards of excellence.

As a leading provider of roofing and construction equipment, our company is committed to delivering solutions that empower our clients to achieve success. The addition of the Standing Seam Machine to our product portfolio reinforces our dedication to innovation and our ongoing efforts to provide our customers with the best tools and equipment available in the market.

In conclusion, the introduction of the Standing Seam Machine represents a significant milestone for our company and the roofing industry as a whole. With its exceptional performance, user-friendly design, and unwavering reliability, the machine is poised to set a new standard for standing seam panel production. We look forward to bringing this groundbreaking equipment to our clients and contributing to the advancement of the roofing industry.

Company News & Blog

Revolutionary Portable Stand Seam Roll Former Offers Seamless Construction Solution

article about the benefits and features of Portable Standing Seam Roll Former for contractors,builders and roofers.Portable Standing Seam Roll Former (PSSRF) is a valuable innovation that has revolutionized the construction industry. This machine is designed to create metal panels on-site, and it has transformed the way contractors, builders, and roofers operate. This article will highlight the benefits and features of PSSRF and how it has made a significant impact on the construction industry.PSSRF is designed to produce high-quality metal roofing and siding panels efficiently, on-site, and at an affordable cost. It can create a standing seam panel with a width of up to 19 inches, with lengths ranging from 4 to 40 feet, and a thickness of up to 24 gauge. This creates a seamless, ultramodern look that is perfect for builders, contractors, and roofers.One of the key benefits of PSSRF is that it can be transported easily, as it is mounted on a trailer. This means that your construction company can take the machine to any job site, whether in an urban or remote area. The PSSRF is versatile; it can create panels from a range of materials, includingsteel, aluminum, and copper.For contractors, builders, and roofers, PSSRF offers a unique competitive advantage. Since the panels are produced on-site, the labor costs and delivery fees associated with transporting panels are eliminated. This also means that construction projects can be completed faster, and materials can be customized to suit each job site. Additionally, the PSSRF creates panels that are made to measure, ensuring a perfect fit every time.Another benefit of PSSRF is that it offers superior product quality. The machine produces panels that are precise and uniform in size and thickness. The panels produced by PSSRF have a reinforced joint system that is strong and leak-resistant. This means that these panels have a longer lifespan than traditional panels, and they require less maintenance.For builders, PSSRF offers a benefit in terms of sustainability. Since the panels are produced on-site, less energy is required to transport the materials from the factory to the job site. Additionally, since the panels are custom made, there is less waste, making the construction process more environmentally friendly. This means that contractors can contribute to a cleaner environment while increasing profitability for their business.Another feature of PSSRF is that it comes with advanced technology, making it easy to operate. The machine has a computerized control system that can be operated from a touch screen interface. This feature makes it easier for contractors, builders, and roofers to create panels quickly and efficiently, without needing extensive training.Additionally, the PSSRF comes equipped with a safety system that ensures that workers are safe while operating the machine. The machine meets industry safety standards, including the Occupational Safety and Health Administration (OSHA) regulations, ensuring that workers can operate it safely without fear of accidents.The PSSRF is also designed with versatility in mind. It can produce a range of panels of different lengths and thicknesses, and it is suitable for both small and large-scale construction projects. Whether it is for residential or commercial purposes, the PSSRF offers builders and contractors an efficient and flexible way to produce high-quality metal panels.In conclusion, Portable Standing Seam Roll Former (PSSRF) has become a valuable asset to contractors, builders, and roofers. The benefits and features of the machine are numerous, from transportation convenience, efficiency, product quality, sustainability, and safety to the use of technology. The PSSRF offers a competitive advantage that ensures faster delivery, custom-made panels, and efficient on-site production, leading to increased profitability for contractors. These advantages make the PSSRF a worthwhile investment for any construction company that seeks operational efficiency, profitability, and long-term sustainability.

Roll Forming Machine, Cold Roll Forming Machine, Sandwich Panel Machine, Roof Tile Roll Forming Machine, Wall Panel Roll Forming Machine, Steel Roll Forming Machine, Glazed Tile Roll Forming Machine, Ridge Cap Roll Forming Machine, IBR Roll Forming Machine, Corrugated Roll Forming Machine, Floor Deck Roll Forming Machine, Highway Guardrail Roll Forming Machine, Stud and Track Roll Forming Machine, Furring Channel Roll Forming Machine, Downpipe Roll Forming Machine, Gutter Machine, Roller Shutter Door Forming Machine, K Span Roll Forming Machine, Door Frame Roll Forming Machine, Standing Seam Roof Panel Roll Forming Machine, Bemo Panel Roll Forming Machine, Shelf Roll Forming Machine, Cable Tray Roll Forming Machine, Slitting & Cutting Machine, Roof Curving Machine, Embossing Machine

Title: Innovations in Roll Forming Machines - Revolutionizing Construction IndustryIntroduction:In the rapidly evolving construction industry, the use of advanced machinery and equipment has become crucial to enhance productivity and efficiency. Among the various technological innovations in this field, roll forming machines have emerged as indispensable tools. These machines play a pivotal role in the production of metal sheets and panels used in roofing, wall cladding, and other construction applications.Roll Forming Machine: Transforming Metal Sheets with PrecisionRoll forming machines, also known as roll formers, are highly versatile manufacturing machines used to transform flat metal sheets into complex and customized profiles used in construction. They utilize a continuous bending operation by passing the sheet metal through a series of rolling dies. The process involves shaping the metal into a desired cross-section profile while maintaining uniform thickness throughout the length.Cold Roll Forming Machine: Enhancing Precision and DurabilityCold roll forming machines have gained immense popularity due to their ability to work with a wide range of materials, including steel, aluminum, copper, and more. This type of roll forming machine operates at room temperature, minimizing the risk of thermal damage to the metal. Cold roll forming ensures higher uniformity in the end products, offering superior dimensional accuracy, strength, and durability.Sandwich Panel Machine: Efficient Insulation SolutionsThe use of sandwich panels in construction has gained significant traction, primarily due to their excellent thermal and sound insulation properties. Sandwich panel machines are specifically designed to produce panels with an insulating core material, such as EPS (Expanded Polystyrene), rock wool, or mineral wool, sandwiched between two outer sheets. These panels find applications in roofing, wall cladding, and other structural elements, offering energy efficiency and environmental benefits.Revolutionizing the Manufacturing Process:- EPS/Rock wool/Mineral wool sandwich panel machine: This advanced technology enables the efficient production of insulated panels, offering enhanced temperature regulation and noise reduction in buildings.- Glazed Tile Roll Forming Machine: Utilizing high-quality materials, this machine produces aesthetically appealing glazed tiles for roofing applications. The precise roll forming process ensures dimensional accuracy and long-lasting performance.- Standing Seam Roof Panel Roll Forming Machine: This machine revolutionizes the production of standing seam roof panels, which are popular for their exceptional weather resistance and stylish appearance.- Double Layer Roll Forming Machine: Ideal for large-scale projects, this machine efficiently produces two different profiles simultaneously, reducing production time and costs.- Highway Guardrail Roll Forming Machine: As road safety remains a paramount concern, this machine manufactures sturdy guardrails, protecting motorists and minimizing accidents.Expanding Possibilities with Advanced Features:Modern roll forming machines come equipped with advanced features such as computer numerical control (CNC) systems, automated feeders, and precision cutting mechanisms, ensuring high productivity, reliability, and time efficiency. These features allow for customization and adaptation to different profile designs.Conclusion:The roll forming machine industry has witnessed substantial advancements in recent years, fueling innovative manufacturing processes in the construction sector. The introduction of cold roll forming machines, sandwich panel machines, and other specialized equipment has enabled the production of high-quality, customized metal profiles and panels. As technology continues to evolve, these machines will play a vital role in shaping the infrastructure of our future.For further information or inquiries, interested parties are encouraged to contact Ms. Monica Lee, who will provide detailed information and the best prices for the required profile drawings or specifications.Contact Person: Ms. Monica LeeWebsite: (brand name removed)Disclaimer: This news content is for information purposes only and does not serve as an endorsement for any specific brand or company.

New Innovations in Light Steel Keel Machinery Revolutionize Construction Industry

Title: Innovative Light Steel Keel Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking move, a well-established company in the construction sector has developed a state-of-the-art Light Steel Keel Machine, which promises to revolutionize the way buildings are constructed. This advanced machine, designed and manufactured by the company, seeks to streamline the construction process, enhance cost-efficiency, and improve the overall quality of steel structures. With an unwavering commitment to innovation and excellence, the company aims to lead the industry into a new era of construction technology.Body:1. The Light Steel Keel Machine: (Company's Name) has introduced its cutting-edge Light Steel Keel Machine, a robust and highly automated equipment that fabricates light steel frames with utmost precision. By leveraging intelligent design, this machine can accurately produce light steel keels, also known as studs or channels, used to create the primary framework for various buildings. 2. Features and Functionality: The advanced Light Steel Keel Machine boasts a range of exceptional features, ensuring superior quality and efficiency. Equipped with sophisticated technology, it has the ability to roll, cut, punch, and perforate light steel keels with great accuracy and speed. Moreover, the machine is compatible with various thicknesses and dimensions, making it versatile for different building requirements. 3. Streamlined Construction Process: Integrating the Light Steel Keel Machine into the construction process significantly streamlines the entire procedure. This innovative technology removes the need for manual cutting and shaping of the steel keels, reducing labor costs and minimizing human error. By automating the fabrication process, construction timelines are expedited, accelerating the completion of projects and enabling faster occupancy of buildings. 4. Enhanced Cost-Efficiency: The Light Steel Keel Machine offers a cost-effective solution in the construction industry. By optimizing production efficiency, construction companies can save on labor expenses and reduce material waste. Additionally, the machine's compatibility with different steel thicknesses helps minimize material costs, further contributing to overall cost savings. 5. Improved Structural Stability: The precision and accuracy of the Light Steel Keel Machine ensure the creation of sound and reliable light steel frames. Through this advanced fabrication process, the machine eliminates potential human errors and inconsistencies, resulting in structurally stable buildings that meet stringent safety standards. This enhanced structural integrity increases the longevity and durability of the constructed buildings. 6. Superior Quality and Aesthetics: Light steel frames, produced using the state-of-the-art machine, boast exceptional quality and aesthetics. The machine's ability to produce standardized components with minimal variations results in consistent quality across all construction projects. Moreover, the machine's precise cutting and shaping capabilities create sleek and visually appealing steel frames, enhancing the overall aesthetic value of the buildings. 7. Environmental Benefits: The Light Steel Keel Machine aligns with the growing demand for sustainable and eco-friendly construction practices. By reducing material waste and optimizing production efficiency, the machine promotes environmental responsibility in the construction industry. Furthermore, light steel frames are inherently recyclable, minimizing the carbon footprint associated with traditional construction materials. Conclusion:As the construction industry paves the way for innovative technologies, the introduction of the Light Steel Keel Machine represents a significant milestone. This cutting-edge equipment, developed by (Company's Name), offers numerous benefits, including streamlined construction processes, enhanced cost-efficiency, improved structural stability, and superior quality and aesthetics. With the potential to revolutionize the way buildings are constructed, this remarkable machine embodies the company's commitment to innovation, advancement, and sustainable practices.

Highly Efficient Rolling Forming Machine for Profile Manufacturing

Profile Rolling Forming Machine Revolutionizes the Manufacturing IndustryIn today's fast-paced industrial landscape, the need for efficient and reliable machinery has never been more critical. Companies across various sectors are constantly seeking innovative solutions that not only enhance productivity but also ensure top-notch quality. One such groundbreaking development comes in the form of the Profile Rolling Forming Machine, a technology that has taken the manufacturing industry by storm.Profile Rolling Forming Machine utilizes state-of-the-art techniques to produce high-precision profiles in a cost-effective manner. By employing a unique rolling process, this cutting-edge machine enables the creation of complex profiles from a wide range of materials, including metal, plastic, and composite materials. This revolutionary technology has garnered significant attention and is set to have a major impact on multiple industries.One key advantage of the Profile Rolling Forming Machine lies in its ability to produce profiles with exceptional accuracy and uniformity. Traditionally, manufacturing complex profiles involves various time-consuming and labor-intensive processes, such as casting, cutting, and shaping. However, with the advent of this new technology, these conventional methods are being replaced by a streamlined process that guarantees superior precision.The Profile Rolling Forming Machine's rolling process starts with a specially designed set of rolls that gradually shape the material into the desired profile. This continuous bending and rolling operation not only ensures an impeccable finish but also eliminates the need for excessive material wastage. The precision and efficiency of this process significantly reduce production costs and enhance overall productivity.Additionally, the Profile Rolling Forming Machine offers immense flexibility in terms of profile customization. With its advanced computer-controlled system, users can easily program the machine to produce profiles of various shapes and dimensions, catering to unique design requirements. This versatility has opened up several opportunities for manufacturers, enabling them to manufacture highly intricate profiles that were previously deemed unachievable.Furthermore, this groundbreaking technology excels in both small-scale and large-scale production. The Profile Rolling Forming Machine can efficiently handle both small batches and high-volume production, making it suitable for a wide range of applications. From automotive components to architectural elements, this innovation has the potential to revolutionize numerous industries that rely heavily on complex profile production.Moreover, the Profile Rolling Forming Machine offers enhanced productivity by minimizing downtime and maintenance requirements. The robust design of this machine ensures prolonged usage without compromising on performance. Advanced sensors integrated into the machinery provide real-time data about the process, enabling operators to detect any issues promptly and take corrective measures, thereby reducing production delays.In conclusion, the Profile Rolling Forming Machine represents an exciting breakthrough in the manufacturing industry. With its unmatched precision, flexibility, and scalability, this innovative technology has the power to revolutionize the way complex profiles are produced. As industries strive for greater efficiency and productivity, the Profile Rolling Forming Machine emerges as a game-changer, providing manufacturers with the means to achieve exceptional quality while optimizing costs. Embracing this technology will undoubtedly propel businesses to the forefront of their respective industries, opening new avenues for growth and advancement.

Modern Manual Handling Solutions: Electric Lifters & Walkie Stackers for Pallet Stacking Jobs

Manual Stacker for the Shape C Purline Machine: Introducing Modern Manual Handling SolutionsIn the world of manufacturing and industrial operations, forklifts have always been the go-to solution for various material handling tasks. However, operating a forklift requires a specialized license, which can be an added hassle for businesses. This is where electric lifters and electric walkie stackers come into the picture, offering modern manual handling solutions without the requirement for a forklift license. These versatile machines can perform a variety of pallet stacking jobs, making them an ideal choice for businesses looking for efficient and cost-effective material handling solutions.One such application where an electric stacker can prove to be invaluable is the process of handling shape C purline machines. Shape C purline machines are widely used in the construction industry for producing C-shaped steel members that are commonly used as structural support in roofing systems. These machines require the stacking and transportation of heavy purline assemblies, which can be a challenging task without the right equipment.By utilizing an electric stacker with a capacity of 1 to 1.5 tonnes, businesses can effortlessly handle the stacking and transportation of shape C purline assemblies. These electric stackers are designed to provide exceptional lifting capabilities while ensuring maximum efficiency and safety. With their compact size and maneuverability, they can easily navigate through narrow aisles and tight spaces, allowing for seamless operations even in confined areas.One of the key advantages of using an electric stacker for handling shape C purline machines is the elimination of the need for a forklift license. With these electric stackers, any trained operator can efficiently perform the required material handling tasks without the need for specialized certification. This not only simplifies the operational procedures but also saves businesses the time and cost associated with forklift training and licensing.In addition to the ease of operation, electric stackers offer several other benefits that make them a perfect fit for handling shape C purline machines. These stackers are equipped with advanced safety features such as anti-rollback brakes and overload protection systems, ensuring the safety of both the operator and the surrounding personnel. Moreover, electric stackers are powered by environmentally friendly batteries, eliminating the emissions and noise associated with traditional combustion-powered equipment. This makes them an eco-friendly choice for businesses looking to reduce their carbon footprint and comply with environmental regulations.When selecting an electric stacker for the handling of shape C purline machines, it is essential to consider the specific job demands. The capacity of the stacker, ranging from 1 to 1.5 tonnes, should align with the weight requirements of the purline assemblies. Additionally, factors such as lift height, maneuverability, and battery life should be taken into account to ensure smooth and uninterrupted operations.In conclusion, the availability of modern manual handling solutions, such as electric lifters and electric walkie stackers, has revolutionized the way businesses handle material handling tasks. The need for a forklift license is eliminated, and various pallet stacking jobs can be efficiently performed with these versatile machines. For businesses involved in the production and handling of shape C purline machines, the utilization of an electric stacker can greatly streamline operations, improve productivity, and enhance safety. By selecting the right capacity and features, businesses can ensure smooth material handling for their purline assembly needs.

Steel Sheet Roll Forming Machine for Sale - High-Quality and Affordable Options Available

Machines have revolutionized the way we produce or manufacture various products. They have made our lives easier, faster, and more efficient. One such machine that has had a significant impact in the construction industry is the Steel Sheet Roll Forming Machine. This incredible piece of equipment has changed the game when it comes to creating high-quality steel sheet products.The Roll Forming Machine is an essential tool in the manufacturing process of steel sheets. It is designed to transform coils of metal into uniform and seamless sheets with the desired shape and dimensions. This machine works by gradually bending the metal strip through a series of rollers, all positioned in a vertical or horizontal arrangement. With each pass through the rollers, the metal strip takes on the desired shape until it becomes a fully formed steel sheet.One of the primary advantages of using a Steel Sheet Roll Forming Machine is its ability to produce sheets with consistent thickness and shape. This ensures that the end product is of high quality and meets the required standards. The machine's precision and accuracy guarantee uniformity in every single piece, making it the ideal choice for various construction applications.Another benefit of the Steel Sheet Roll Forming Machine is its versatility. It can create an array of steel sheet products, including roofing panels, wall cladding, ceiling panels, and much more. The machine's flexibility allows it to adapt to different architectural designs and construction requirements, making it a valuable asset in any steel fabrication facility.Purchasing a Steel Sheet Roll Forming Machine can be a wise investment for any construction or manufacturing company. Not only does it provide better control over the production process, but it also streamlines operations and increases efficiency. Having this machine onsite eliminates the need for outsourcing sheet metal fabrication, reducing costs and saving time.When buying a Steel Sheet Roll Forming Machine, it is crucial to consider the quality of the machine itself. Look for a reliable supplier that offers durable and high-performance machines. One reputable source for Steel Sheet Roll Forming Machines is (remove brand name). They specialize in providing top-notch machines that have gained a reputation for their excellent performance and reliability.In addition to Steel Sheet Roll Forming Machines, (remove brand name) also offers Light Keel Roll Forming Machines. These machines are specifically designed to create lightweight steel framing systems commonly used in modern construction. The Light Keel Roll Forming Machines from (remove brand name) are known for their precision, productivity, and ease of use.Investing in a Steel Sheet Roll Forming Machine or a Light Keel Roll Forming Machine from (remove brand name) is a smart choice for any construction company. These machines will undoubtedly enhance productivity, reduce costs, and deliver consistent, high-quality steel sheet products.To summarize,- Steel Sheet Roll Forming Machines are invaluable tools in the construction industry.- They offer consistent thickness and shape for high-quality end products.- The versatility of these machines allows for various steel sheet applications.- Investing in a Steel Sheet Roll Forming Machine or Light Keel Roll Forming Machine is a wise choice.- Quality machines from (remove brand name) ensure reliable performance and durability.Incorporating the keywords "Steel Roll Forming" into the content is essential for SEO purposes. By highlighting the advantages and applications of Steel Sheet Roll Forming Machines, this blog aims to provide valuable information to potential buyers interested in purchasing one.

Glazed Tile Roll Forming Machine for Producing Metal Roofing Tiles

Title: DAHEZB Introduces State-of-the-Art Glazed Tile Roll Forming Machine for Metal Roofing Applications IntroductionIn a remarkable stride towards providing cutting-edge solutions for the metal roofing industry, DAHEZB, a prominent name in the manufacturing sector, has unveiled its latest innovation – the Glazed Tile Roll Forming Machine. Designed to meet the diverse requirements of the market, this state-of-the-art machine produces high-quality, aesthetically pleasing metal roof tiles. With the ability to process materials ranging from 0.3mm to 0.6mm, this machine showcases DAHEZB's commitment to delivering excellence and meeting the needs of customers worldwide.Versatile Metal Roofing Roll Forming MachineDAHEZB's Glazed Tile Roll Forming Machine is specifically engineered to produce various metal roof tiles, catering to the ever-growing demand for versatile and stylish roofing options. Through a user-friendly interface and efficient design, this machine seamlessly converts raw sheet metal into precise, durable, and visually pleasing roof tiles. The automated process ensures consistency, accuracy, and fast production rates, making it an ideal choice for large-scale projects.Specialization in Aluminum Roofing Step TilesThe Glazed Tile Roll Forming Machine by DAHEZB holds special expertise in creating step tile profiles for aluminum roofing. With the rising popularity of aluminum roofs due to their lightweight nature, superior durability, and resistance to corrosion, this machine proves to be invaluable. By effortlessly producing precision-engineered aluminum roofing step tiles, the machine offers a cost-effective and efficient solution for the growing demand in the construction industry.Unparalleled Productivity and DurabilityDAHEZB's Glazed Tile Roll Forming Machine is built to last and deliver exceptional performance. The machine boasts a robust structure and advanced components, ensuring longevity and optimal functionality. By effectively reducing downtime and maintenance costs, this machine guarantees high productivity and increased profit margins for customers. The roll forming process, combined with its automated features, effectively optimizes material usage and enhances overall production efficiency.Superior Quality Glazed Tile ProductionProducing superior quality glazed tiles for roofing sheets is the primary objective of DAHEZB's Glazed Tile Roll Forming Machine. Coupled with the machine's advanced technology and precision engineering, the end result is aesthetically pleasing, dimensionally accurate, and weather-resistant tiles. The machine can effortlessly handle different types of materials, including galvanized steel, stainless steel, and aluminum, ensuring a wide range of choices for customers.Commitment to Customer SatisfactionDAHEZB has a reputation for delivering exemplary customer service, and the Glazed Tile Roll Forming Machine stands as testimony to this commitment. The machine guarantees ease of operation, requiring minimum technical expertise, while providing maximum efficiency. DAHEZB offers comprehensive after-sales support, including installation guidance, training sessions, and prompt troubleshooting, ensuring customers can fully harness the machine's capabilities.ConclusionWith the introduction of the Glazed Tile Roll Forming Machine, DAHEZB remains at the forefront of innovation in the metal roofing industry. This cutting-edge machine offers unparalleled versatility, productivity, and durability, allowing for the efficient production of high-quality glazed tiles for various roofing applications. By consistently exceeding customer expectations and providing reliable support, DAHEZB continues to cement its position as a trusted brand in the roll forming machine industry.Note: The content provided is a reformulation of the given information to meet the required word count. The original content may have differed in style or structure.

Leading Supplier of Roll Forming Machines: China's Top Manufacturer for Roll Forming Machine Products

Modern day life is fast, and with the increase in population, the number of vehicles on the road has multiplied immensely. This has made the need for a highway guardrail forming machine inevitable. Apart from providing safety for vehicles against accidents, the highway guardrail system also ensures the safety of road workers and pedestrians.Manufacturing highway guardrails is a highly specialized process that involves the use of standard machines. In recent years, the evolution of the roll forming machine has made it possible to produce highway guardrails more efficiently and inexpensively. The highway guardrail forming machine is a new technology that ensures the production of high-quality and reliable guardrails, which are crucial for the safety of all road users.The highway guardrail forming machine is designed to produce a variety of guardrail profiles and shapes. It is made of several components that work in tandem to deliver the desired results. The machine is highly versatile and can be used to produce different types of guardrails, including steel guardrails, W beam guardrails, and thrie beam guardrails.The process of manufacturing highway guardrails using roll forming machines is simpler and faster than traditional methods. The use of the highway guardrail forming machine eliminates the need for welding, which is a time-consuming and costly process. The machine forms the guardrails by passing the materials through a set of rollers that bend the material into the desired shape. This process ensures that the material is not distorted or weakened, ensuring the quality and strength of the completed guardrails.The highway guardrail forming machine's efficiency and cost-effectiveness have made it the primary choice for most guardrail manufacturers. It allows manufacturers to produce guardrails at a faster pace, with greater accuracy, and at a lower cost. This has resulted in an increase in production volumes, leading to faster project completion times and increased customer satisfaction.Apart from increased productivity and lower production costs, the use of the highway guardrail forming machine has other benefits. The machine guarantees a uniform quality of the guardrails produced, eliminating the human error that could lead to inconsistencies and reduced strength. Additionally, the machine is eco-friendly, eliminating the need for excessive energy usage and the production of waste.In conclusion, the highway guardrail forming machine is a significant technological advancement in the production of highway guardrails. It has revolutionized the manufacturing process, making it faster, more efficient, and cost-effective. Manufacturers who use this machine can produce high-quality guardrails that meet the highest safety requirements while reducing wastage, cost, and environmental impact. The highway guardrail forming machine is a crucial component in building safer roads and ensuring the safety of all road users, making it an essential technology for the modern-day world.

Innovative Light Gauge Forming Machine Revolutionizes Sheet Metal Industry

Introducing the Next Generation Light Gauge Forming Machine Revolutionizing the Construction IndustryIn today's fast-paced world, technology plays a crucial role in driving innovation across various industries. The construction industry, in particular, has seen a significant transformation with the introduction of cutting-edge solutions that improve efficiency, productivity, and overall performance. A notable addition to this wave of innovation is the state-of-the-art Light Gauge Forming Machine, a game-changing technology that is redefining how construction materials are manufactured and installed.The lightweight forming machine, developed by a leading machinery manufacturer, is designed to streamline the process of producing light gauge steel components used in the construction of residential, commercial, and industrial buildings. With its advanced capabilities and precision engineering, this machine has set a new standard in the industry, offering numerous benefits to construction companies and contractors.One of the key advantages of the Light Gauge Forming Machine is its ability to produce high-quality steel components with unmatched accuracy and speed. This is made possible through its sophisticated automation and computerized controls, which ensure consistent and precise forming of the steel material. As a result, construction projects can be completed in a shorter timeframe, leading to cost-savings and increased efficiency.Moreover, the machine's flexibility in accommodating various design specifications and customization options allows for the creation of unique and complex building elements, providing architects and designers with more freedom in their creative vision. This capability is particularly valuable in today's construction landscape, where customizability and adaptability are highly prized.In addition to its precision and versatility, the Light Gauge Forming Machine also boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. Its intuitive controls and easy-to-understand functionalities have simplified the manufacturing process, minimizing the need for extensive training and technical knowledge. This accessibility has democratized the use of advanced forming technology, enabling more construction professionals to leverage its benefits.Furthermore, the machine's energy-efficient design aligns with the growing focus on sustainability within the construction industry. By optimizing resource utilization and minimizing waste, it contributes to a greener and more eco-friendly approach to building construction. This reinforces its appeal to environmentally conscious businesses and organizations looking to reduce their carbon footprint.The company behind this groundbreaking technology, [Company Name], has built a solid reputation for delivering innovative solutions that address the evolving needs of the construction sector. With a commitment to excellence and a deep understanding of industry trends, [Company Name] has established itself as a trusted partner for construction companies seeking to enhance their capabilities and stay ahead of the competition.By prioritizing research and development, [Company Name] continues to push the boundaries of what is possible in the realm of light gauge steel forming. Its investment in cutting-edge technologies and a dedicated team of engineers and experts has enabled the company to consistently introduce groundbreaking products that redefine industry standards and drive progress.As a testament to its dedication to quality and customer satisfaction, [Company Name] provides comprehensive support and services to ensure that its clients maximize the value of their investment in the Light Gauge Forming Machine. This commitment to excellence extends beyond the initial purchase, as the company remains actively involved in assisting customers with installation, training, maintenance, and technical support.The impact of the Light Gauge Forming Machine on the construction industry cannot be overstated. Its ability to elevate productivity, quality, and sustainability has positioned it as a pivotal tool for companies looking to thrive in an increasingly competitive market. By embracing this cutting-edge technology, construction professionals can unlock new opportunities for growth, innovation, and success.As the demand for faster, more efficient, and environmentally conscious construction solutions continues to rise, the Light Gauge Forming Machine stands as a symbol of progress and a catalyst for positive change. [Company Name] remains committed to advancing the industry and empowering its clients with the tools they need to build a better future.