Ultimate Guide to Wall Panel Roll Forming Machine: Everything You Need to Know

By:Admin

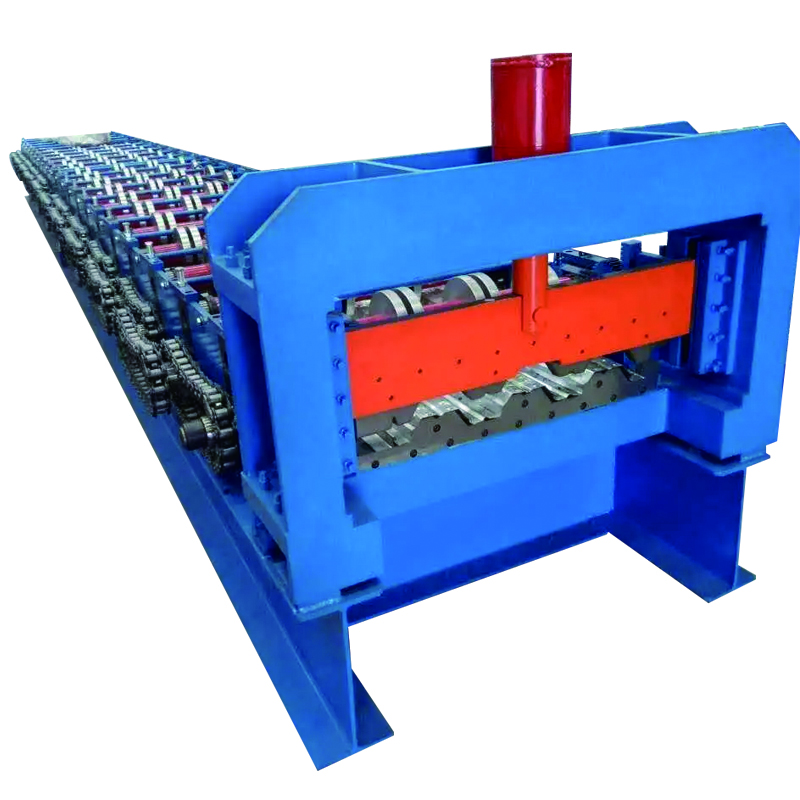

The wall panel roll forming machine offered by (remove brand name) is designed to meet the specific requirements of modern construction projects. It is equipped with the latest technology and precision engineering, allowing for the seamless production of high-quality wall panels with various profiles, dimensions, and materials. The machine's advanced control system ensures accurate and consistent panel production, while its robust construction and high-speed operation contribute to increased productivity and efficiency.

One of the key advantages of (remove brand name)’s wall panel roll forming machine is its versatility. It is capable of producing a wide range of wall panel profiles, including but not limited to corrugated, trapezoidal, and standing seam panels. This flexibility makes it an ideal choice for construction companies and manufacturers seeking to diversify their product offerings and meet the evolving needs of the market.

In addition to its advanced technology and versatile capabilities, (remove brand name)’s wall panel roll forming machine is also known for its user-friendly design and ease of operation. The machine is equipped with intuitive controls and interfaces, making it accessible to operators of varying skill levels. Furthermore, it is built for durability and low maintenance, ensuring a reliable and cost-effective solution for long-term panel production.

Behind the success of (remove brand name)’s wall panel roll forming machine is its parent company, {}, a leading manufacturer of roll forming machines and other industrial equipment. With a strong focus on innovation and customer satisfaction, {} has established itself as a trusted provider of high-quality production solutions for the construction and manufacturing sectors. Its commitment to research and development, as well as its attention to industry trends and customer feedback, has enabled the company to continuously improve and expand its product range.

The introduction of the wall panel roll forming machine is a testament to {}'s dedication to meeting the evolving needs of its customers and the market. By leveraging its expertise in roll forming technology and its understanding of the construction industry, the company has developed a solution that addresses the demand for efficient, versatile, and reliable panel production. Moreover, its commitment to customer support and after-sales service ensures that clients can fully maximize the potential of the machine and achieve their production goals.

As the construction industry continues to embrace innovation and automation, the demand for advanced production solutions like (remove brand name)’s wall panel roll forming machine is expected to grow. With its track record of quality and performance, backed by the reputation and expertise of {}, this machine is poised to make a significant impact on the market and contribute to the advancement of modern construction practices.

In conclusion, the introduction of (remove brand name)’s wall panel roll forming machine marks a significant milestone for the company and the construction industry. With its advanced technology, versatility, and user-friendly design, this machine offers a compelling solution for companies seeking to enhance their panel production capabilities. As part of {}, a trusted leader in roll forming technology, this machine embodies the company's commitment to innovation, quality, and customer satisfaction. It is poised to make a lasting impact on the market and contribute to the evolution of modern construction practices.

Company News & Blog

High-Quality Steel Sheet Roll Forming Machine for Decking Projects

Introducing the Latest Innovation in Steel Sheet Roll Forming: The Decking Steel Sheet Roll Forming MachineThe steel industry has always been a crucial part of the infrastructure and construction sector, providing the necessary materials for building strong and durable structures. In line with this, the introduction of the latest innovation in steel sheet roll forming, the Decking Steel Sheet Roll Forming Machine, has been welcomed with enthusiasm and anticipation. Developed by a leading company in the field of manufacturing and engineering {}, this new machine is set to revolutionize the way steel decking sheets are produced.The Decking Steel Sheet Roll Forming Machine is designed to cater to the growing demand for high-quality and precise steel decking sheets, which are widely used in the construction of commercial and industrial buildings. With its advanced technology and efficient production capabilities, this machine is expected to deliver superior performance and reliability, while also streamlining the manufacturing process for companies in the steel industry.The key features of the Decking Steel Sheet Roll Forming Machine include a robust and durable frame, precision-engineered rollers, and a user-friendly control system. These components work together to ensure consistent and accurate forming of steel sheets, resulting in products that meet the highest standards of quality and performance. Additionally, the machine is equipped with safety features and automated functions, making it easy to operate and maintain, while also minimizing the risk of errors and accidents in the production process.In addition to its technical capabilities, the Decking Steel Sheet Roll Forming Machine is also designed with versatility and flexibility in mind. It can accommodate a wide range of steel sheet sizes and thicknesses, allowing manufacturers to produce a variety of decking sheets according to their specific requirements. This adaptability makes the machine a valuable asset for companies that need to cater to diverse customer demands and industry standards.The company {} has a strong reputation for delivering cutting-edge solutions in the field of roll forming and metal fabrication. With a team of experienced engineers and technicians, the company is committed to providing innovative and reliable equipment that meets the evolving needs of the industry. The introduction of the Decking Steel Sheet Roll Forming Machine is a testament to this dedication, as it represents a significant advancement in the company's product portfolio and an important contribution to the steel manufacturing sector.The company's commitment to quality and excellence is reflected in its state-of-the-art manufacturing facilities and stringent quality control measures. Every machine undergoes thorough testing and inspection to ensure that it meets the highest standards of performance and durability. Customers can have confidence in the reliability and longevity of the Decking Steel Sheet Roll Forming Machine, knowing that it has been built and tested to deliver superior results in real-world production environments.Furthermore, the company {} is known for its comprehensive customer support and after-sales service. From installation and training to maintenance and technical assistance, the company provides end-to-end support to its customers, ensuring that they get the most out of their investment in the Decking Steel Sheet Roll Forming Machine. This commitment to customer satisfaction and success sets the company apart as a trusted partner for businesses seeking to enhance their steel manufacturing capabilities.In conclusion, the introduction of the Decking Steel Sheet Roll Forming Machine by {} marks a significant advancement in the field of steel sheet roll forming. With its cutting-edge technology, versatile capabilities, and unwavering commitment to quality, this machine is set to raise the bar for the production of steel decking sheets. As the industry continues to evolve and demand for high-performance steel products grows, the Decking Steel Sheet Roll Forming Machine stands ready to meet the challenges and opportunities of the future.

High-Quality Glazed Tile Panel Roll Forming and Corrugation Machine for Sale

Glazed Tile Panel Roll Forming And Corrugation Machine (Name Removed) has become a popular choice among construction professionals for its ability to efficiently produce high-quality glazed tile panels and corrugated metal sheets. The machine is designed to meet the growing demand for durable and aesthetically pleasing roofing and cladding materials, particularly in the residential and commercial sectors.The roll forming and corrugation machine from (Name Removed) is known for its precision and reliability, making it an essential tool for manufacturers and contractors looking to meet tight production deadlines without compromising on quality. With its advanced technology and user-friendly interface, the machine has quickly become the go-to solution for businesses looking to streamline their production processes and maximize their output.One of the key features of the (Name Removed) roll forming and corrugation machine is its versatility. It is capable of producing a wide range of glazed tile panels and corrugated metal sheets, allowing businesses to cater to diverse customer requirements. Whether it's a traditional or modern design, the machine can effortlessly produce panels and sheets that meet industry standards and exceed customer expectations.In addition to its flexibility, the (Name Removed) roll forming and corrugation machine is also praised for its efficiency. The machine is designed to minimize material waste and maximize production yield, helping businesses optimize their resources and reduce production costs. This not only benefits the bottom line but also contributes to sustainability efforts by reducing the environmental impact of manufacturing processes.Moreover, the roll forming and corrugation machine is equipped with state-of-the-art safety features to ensure a secure working environment for operators. This includes built-in safeguards and emergency stop mechanisms that prioritize the well-being of workers and prevent accidents from occurring during operation.The (Name Removed) roll forming and corrugation machine is the result of years of research and development by a company that is dedicated to delivering innovative solutions for the construction industry. With a strong commitment to quality and performance, the company has established itself as a leader in the manufacturing of roll forming and corrugation machinery, earning the trust and loyalty of customers worldwide.Founded (Year Established), (Company Name) has continually invested in cutting-edge technology and engineering expertise to develop a wide range of industrial machinery. The company's dedication to research and development has led to the creation of innovative solutions that have redefined industry standards and empowered businesses to achieve new levels of success.In addition to its commitment to product excellence, (Company Name) is also known for its customer-centric approach. The company takes pride in providing exceptional service and support to its customers, offering comprehensive training programs and technical assistance to ensure that businesses can fully leverage the capabilities of their machinery.Furthermore, (Company Name) operates with a strong focus on sustainability and corporate social responsibility. The company adheres to rigorous environmental standards and implements eco-friendly practices in its manufacturing processes, demonstrating its dedication to minimizing its carbon footprint and contributing to a greener future.As the construction industry continues to evolve, the demand for high-performance roll forming and corrugation machinery is expected to grow. With its superior capabilities and unwavering commitment to customer satisfaction and sustainability, (Name Removed) and (Company Name) are well-positioned to meet the needs of businesses operating in this dynamic sector.In conclusion, the glazed tile panel roll forming and corrugation machine from (Name Removed) is revolutionizing the production of roofing and cladding materials, offering businesses the tools they need to thrive in a competitive market. With its advanced technology, versatility, efficiency, and commitment to excellence, the machine is set to play a pivotal role in shaping the future of the construction industry.

Revolutionary Cold Formed Steel Machine Disrupts Construction Industry

Cold Formed Steel Machine: Paving the Way to Innovative Steel ConstructionInvented over a century ago, cold forming is a manufacturing process that has evolved to revolutionize the steel construction industry. Cold formed steel (CFS) offers significant advantages over wood and traditional hot-rolled steel, including durability, sustainability, and adaptability. It's also more cost-effective and easier to install, making it an ideal choice for framing, roofing, and wall panels in commercial and residential buildings.Today, the trend towards offsite construction and modular building is driving the demand for high-quality, precision cold formed steel machines that can deliver the desired outputs in a timely and cost-effective manner. One company that has stepped up to the challenge is [Brand name], a leading supplier of cold formed steel machines and roll forming systems worldwide.With over 20 years' experience in the industry, [Brand name] has gained a reputation for excellence through its innovative and reliable solutions for the production of CFS sections. From stud and track roll forming machines to roof panel and purlin roll forming machines, [Brand name]'s offerings provide the flexibility, accuracy, and speed required to meet various customers' needs.One of [Brand name]'s most popular machines is its patented roll forming system for cold-formed steel frames. This innovative system uses patented software and advanced technologies to produce customized CFS studs, tracks, and joists with precision and efficiency. Unlike traditional roll forming machines, which may require significant setup time and adjustments, [Brand name]'s system can be programmed to produce various sizes and shapes of CFS sections, making it ideal for low-volume, high-mix production runs.Moreover, [Brand name]'s cold formed steel machines are designed with the operator's safety and ease of use in mind. The company's engineers have developed advanced control systems that allow operators to have real-time remote access to the machine's status and performance, minimizing downtime and enhancing productivity. In addition, the machines are equipped with easy-to-use touchscreen interfaces that simplify the setup and configuration process.But what sets [Brand name]'s cold formed steel machines apart from the competition is the company's customer-centric approach that emphasizes collaboration, reliability, and flexibility. When customers choose [Brand name], they don't just get a machine — they get a team of highly qualified engineers and technicians who work closely with them to identify their needs, provide tailored solutions, and ensure the machines meet or exceed their expectations.At [Brand name], customer satisfaction is paramount. That's why the company provides excellent technical support via on-site training, remote assistance, and maintenance services to help customers get the most out of their investment. [Brand name]'s team of experts is also available to provide expert advice on the design, installation, and operation of the machines, as well as the most appropriate materials and accessories to use.As a testament to its commitment to quality and innovation, [Brand name] has received numerous accolades and recognitions over the years. For instance, the company was awarded the prestigious "National Key High-Tech Enterprise" and "Innovative Enterprise" titles by the Chinese government in 2020. These awards recognize [Brand name]'s contributions to the development of the cold formed steel industry and its commitment to advancing the latest technologies and techniques.In summary, the cold formed steel industry is poised for significant growth in the coming years, driven by the need for fast, efficient, and sustainable construction solutions. With its cutting-edge cold formed steel machines and its unwavering dedication to customer service, [Brand name] is well-positioned to help customers unlock the full potential of cold formed steel and to lead the industry forward.

High-quality Floor Production Roll Forming Machine for Efficient Manufacture

Floor Production Roll Forming Machine revolutionizes the industry with its advanced technology and innovative features. This cutting-edge machine is set to redefine the way floor production is done, offering a range of benefits and advantages that are unmatched in the market.Designed and developed by the industry-leading team at {}, this new Floor Production Roll Forming Machine is equipped with state-of-the-art technology and precision engineering. The machine is capable of producing high-quality floor panels with unparalleled accuracy and efficiency, making it a game-changer for the industry.One of the key features of the Floor Production Roll Forming Machine is its ability to handle a wide variety of materials, including steel, aluminum, and other metals. This versatility allows manufacturers to produce a diverse range of floor panels to meet the specific requirements of different projects. Furthermore, the machine is designed to be easy to operate and maintain, minimizing downtime and maximizing productivity.The Floor Production Roll Forming Machine also boasts a high level of customization, allowing manufacturers to tailor the machine to their specific needs. Its modular design and flexible configuration options make it adaptable to different production processes, making it a versatile and cost-effective solution for floor panel manufacturing.In addition to its advanced technology, the Floor Production Roll Forming Machine is also designed with a focus on energy efficiency and sustainability. The machine is equipped with cutting-edge energy-saving features that help reduce power consumption and minimize environmental impact, making it an eco-friendly choice for manufacturers.With its combination of advanced technology, versatility, and sustainability, the Floor Production Roll Forming Machine is set to make a significant impact on the industry. It offers manufacturers a competitive edge by enabling them to produce high-quality floor panels with greater efficiency and cost-effectiveness, ultimately boosting their bottom line.The team at {} is proud to introduce this groundbreaking Floor Production Roll Forming Machine to the market. With their decades of experience and expertise in roll forming technology, they have once again raised the bar for innovation and excellence in the industry.As a leading manufacturer of roll forming machines, {} has a strong track record of delivering top-quality solutions to the market. Their commitment to innovation and customer satisfaction has solidified their reputation as a trusted partner for manufacturers seeking cutting-edge roll forming technology.The launch of the Floor Production Roll Forming Machine marks a significant milestone for the company, as they continue to push the boundaries of what is possible in the industry. By leveraging their expertise and insights, they have developed a machine that is set to redefine the standards for floor panel production.With its exceptional capabilities and unmatched performance, the Floor Production Roll Forming Machine from {} is poised to become an indispensable tool for manufacturers looking to stay ahead in a competitive market. It represents a new era of efficiency, precision, and sustainability in floor panel production, setting a new benchmark for the industry.In conclusion, the Floor Production Roll Forming Machine from {} is a groundbreaking innovation that is set to transform the way floor panels are produced. With its advanced technology, versatility, and sustainability, it offers manufacturers a powerful tool to enhance their capabilities and drive success in the market. As {} continues to lead the way in roll forming technology, the industry can look forward to more game-changing solutions that raise the bar for excellence.

High-Quality Single Layer Color Steel Roll Forming Machine at Competitive Prices

Introducing a New and Advanced Single Layer Color Steel Roll Forming MachineAs technology continues to advance, the roll forming industry is also experiencing significant transformation. In line with this, the renowned company {}, a leading manufacturer of roll forming machines, is pleased to announce the launch of their latest innovation - the Single Layer Color Steel Roll Forming Machine. This advanced machine is set to revolutionize the manufacturing process for color steel products, offering enhanced efficiency and superior quality.The Single Layer Color Steel Roll Forming Machine is designed to meet the growing demand for color steel products in various industries such as construction, automotive, and household appliances. With its advanced features and innovative technology, this machine sets a new standard for roll forming equipment.One of the key features of this machine is its ability to produce single layer color steel products with exceptional precision and consistency. This is made possible through the use of high-quality materials and advanced manufacturing techniques, ensuring that the end products meet the highest standards of quality and durability.In addition, the Single Layer Color Steel Roll Forming Machine is designed for versatility, allowing for the production of a wide range of color steel products such as roofing panels, wall cladding, and decking sheets. This flexibility makes it an ideal solution for manufacturers looking to expand their product offerings and meet the diverse needs of their customers.Furthermore, this machine is equipped with advanced control systems and automation technology, enabling seamless operation and minimizing the need for manual intervention. This not only increases productivity but also ensures consistent product quality, reducing the risk of errors and defects.The company {} has a long-standing reputation for delivering high-quality roll forming machines, backed by their commitment to innovation and customer satisfaction. With the introduction of the Single Layer Color Steel Roll Forming Machine, they continue to uphold this tradition by providing manufacturers with a cutting-edge solution that will help them stay ahead in a competitive market.In addition to its innovative products, {} offers comprehensive technical support and maintenance services to ensure that their customers can maximize the performance and lifespan of their machines. This commitment to customer service sets them apart as a trusted partner for manufacturers in the roll forming industry.As a company with a global presence, {} is dedicated to meeting the needs of their diverse customer base, providing tailored solutions to address unique manufacturing challenges. With the launch of the Single Layer Color Steel Roll Forming Machine, they are poised to further strengthen their position as a leading provider of roll forming equipment worldwide.In conclusion, the Single Layer Color Steel Roll Forming Machine from {} represents a significant advancement in roll forming technology, offering unparalleled precision, efficiency, and versatility. With its cutting-edge features and industry-leading performance, this machine is set to make a lasting impact on the manufacturing of color steel products. As the roll forming industry continues to evolve, {} remains at the forefront, driving innovation and delivering solutions that empower manufacturers to thrive in a dynamic market.

Cut to Length Machine: A Complete Guide for Steel Cutting Operations

Steel Cut To Length Machine revolutionizing the metalworking industryIn the world of metalworking, precision and efficiency are key components of success. The Steel Cut To Length Machine, produced by a leading manufacturer in the industry, is revolutionizing the way steel is processed and cut. This state-of-the-art machine combines cutting-edge technology with the company's expertise and dedication to excellence, making it a game-changer for businesses in the metalworking sector.With a strong commitment to innovation and quality, {company name} has established itself as a leader in the manufacturing of metalworking machinery. The Steel Cut To Length Machine is a testament to the company's dedication to providing cutting-edge solutions to its customers. With a focus on precision and efficiency, this machine is designed to streamline the process of cutting steel, providing businesses with a cost-effective and reliable solution for their metalworking needs.One of the key features of the Steel Cut To Length Machine is its advanced cutting technology. Equipped with high-precision blades and state-of-the-art automation, this machine is capable of cutting steel with unparalleled accuracy and speed. This precision cutting technology ensures that businesses can produce high-quality steel products with minimal waste, saving both time and money in the production process.Another notable feature of the Steel Cut To Length Machine is its versatility. This machine is designed to handle a wide range of steel thicknesses and widths, making it suitable for a variety of metalworking applications. Whether businesses are working with thin-gauge steel or heavy-duty materials, this machine is capable of delivering consistent and precise cuts, ensuring that the finished products meet the highest standards of quality.In addition to its cutting-edge technology and versatility, the Steel Cut To Length Machine is also designed with user-friendliness in mind. The machine's intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, streamlining the production process and minimizing the potential for errors. This user-friendly design is a testament to {company name}'s commitment to providing its customers with practical and efficient solutions for their metalworking needs.For businesses in the metalworking industry, investing in the Steel Cut To Length Machine represents a step forward in achieving greater productivity and efficiency. By incorporating this cutting-edge machine into their operations, businesses can optimize their production processes, reduce waste, and ultimately improve their bottom line. With the support of {company name}'s expertise and commitment to excellence, the Steel Cut To Length Machine is helping businesses in the metalworking sector stay ahead of the competition.In conclusion, the Steel Cut To Length Machine, produced by {company name}, is transforming the metalworking industry with its cutting-edge technology, versatility, and user-friendly design. With a focus on precision and efficiency, this machine is empowering businesses to achieve greater productivity and cost-effectiveness in their operations. As the demand for high-quality steel products continues to grow, the Steel Cut To Length Machine is positioning businesses in the metalworking sector for success, driving innovation and progress in an ever-evolving industry.

Flat Roof Rubber Sheet: Unparalleled Corrugated Metal Roof for Pergolas Unmatched Corrugated Metal Roofing Sheets in Scotland Tile Effect Metal Roofing Sheets, Radiant Barrier Material, Galvanized Steel Sheet Metal, Wood Support Brackets, Eagle Carports, Target Stand, Colored Metal Panels, Mono Pitch Roof Calculator, Tom Roof, Charcoal Roof Tiles, Corrugated Colorbond Sheets: The Ultimate Solution Premium Quality Flat Roof Rubber Sheet for Your Roofing Needs

Title: A New Approach to Roofing Solutions: Horizontal Corrugated Roof PanelIntroduction:In a world where sustainability and durability are becoming paramount, the roofing industry has witnessed tremendous advancements. This article focuses on an innovative product, the Horizontal Corrugated Roof Panel, offered by (need to remove brand name), which aims to revolutionize traditional roofing solutions. With its exceptional features and benefits, this unique product has garnered significant attention in the market.A Versatile Solution for All: The Horizontal Corrugated Roof Panel offers versatility in terms of its applications. The product is designed to cater to various roofing needs, including pergolas, carports, and commercial and residential buildings. Whether it's a traditional or contemporary architectural design, this panel effortlessly complements any structure, showcasing its adaptability.Unmatched Durability and Longevity:One significant advantage of the Horizontal Corrugated Roof Panel is its exceptional durability. Made of high-quality galvanized steel sheet metal, this product offers unparalleled strength and resistance against harsh weather conditions, including heavy rains, intense UV exposure, and strong winds. Additionally, the panel's unique design ensures its longevity, offering a sustainable roofing solution that requires minimal maintenance.Enhancing Energy Efficiency:The Horizontal Corrugated Roof Panel is a high-performance roofing material that integrates a radiant barrier material within its structure. This innovative feature reflects heat away from the structure, reducing the amount of heat transferred inside. As a result, buildings experience improved energy efficiency, reducing the reliance on HVAC systems and resulting in substantial energy cost savings.Aesthetically Pleasing and Customizable:Gone are the days when roofing sheets were merely utilitarian. The Horizontal Corrugated Roof Panel embraces contemporary design trends, presenting itself as a visually appealing option. With its tile effect metal roofing sheets, buildings can achieve a desirable aesthetic appeal that replicates the beauty of traditional tile roofs. Additionally, the product comes in a variety of colors, allowing for customization and personalization to suit individual preferences.Easy Installation and Cost-Effective Solution:Not only does the Horizontal Corrugated Roof Panel offer exceptional durability and aesthetics, but it also provides an easy and hassle-free installation process. With its wood support brackets, the panels can be quickly assembled, reducing labor costs and project timelines. This efficiency makes it an ideal option for both small-scale residential projects and large-scale commercial installations.Environmental Sustainability:In a time when sustainability is of paramount importance, the Horizontal Corrugated Roof Panel stands out for its environmentally conscious approach. Made with recyclable materials such as galvanized steel, this product is an eco-friendly alternative to traditional roofing options. Additionally, its ability to enhance energy efficiency contributes to reducing carbon emissions and overall environmental impact.Conclusion:The Horizontal Corrugated Roof Panel offered by (need to remove brand name) is revolutionizing roofing solutions with its durability, energy efficiency, aesthetic appeal, and sustainability. As the need for reliable and cost-effective roofing materials grows, this innovative product emerges as a game-changer in the industry. Whether for residential or commercial applications, this versatile and long-lasting roofing solution provides a viable alternative for those seeking excellence in both functionality and design.

High-Quality Steel Rollforming Machines for Sale: Find the Best Deals Now

Steel rollforming machines are revolutionizing the construction industry with their ability to efficiently produce high-quality metal profiles for various applications. The advancements in technology have made it possible to manufacture these machines with precision and reliability, leading to increased productivity and cost savings for companies around the world. One company that has been at the forefront of this innovation is [Company Name], a leading manufacturer of steel rollforming machines.[Company Name] has been in the business of designing and manufacturing rollforming machines for over 20 years. Their commitment to excellence and continuous improvement has made them a trusted partner for companies in the construction industry. With a team of experienced engineers and technicians, [Company Name] has been able to develop advanced rollforming machines that meet the specific needs of their customers.The company's rollforming machines are designed to produce a wide range of metal profiles, including roof panels, wall cladding, and custom profiles. These machines are equipped with state-of-the-art technology that allows for precise forming of metal sheets, resulting in accurate and consistent profiles. The use of advanced control systems ensures that the machines operate with high efficiency and minimal material waste, leading to cost savings for the customers.One of the key features of [Company Name]'s rollforming machines is their flexibility and versatility. The machines can be customized to meet the unique requirements of different projects, allowing for the production of a wide variety of metal profiles. This flexibility is essential for companies that need to adapt to changing market demands and offer a diverse range of products to their customers.In addition to their technical capabilities, [Company Name] prides itself on providing excellent customer service and support. The company works closely with its customers to understand their specific needs and provide tailored solutions that meet their requirements. From the initial consultation to the installation and commissioning of the machines, [Company Name] ensures that its customers receive the support they need to maximize the performance of the rollforming machines.The rollforming machines manufactured by [Company Name] are also known for their durability and reliability. The use of high-quality materials and components, along with rigorous quality control processes, ensures that the machines are built to last. This reliability is essential for companies that rely on the continuous operation of their rollforming machines to meet their production targets.As the construction industry continues to evolve, the demand for efficient and reliable rollforming machines will only grow. Companies that invest in advanced rollforming technology will be well-positioned to capitalize on the opportunities in the market and stay ahead of the competition. With its commitment to innovation and customer satisfaction, [Company Name] is poised to remain a leader in the industry and continue to provide cutting-edge solutions for its customers.In conclusion, steel rollforming machines have become an essential tool for companies in the construction industry, and [Company Name] has established itself as a leading manufacturer of these machines. With a focus on innovation, quality, and customer satisfaction, the company has been able to deliver advanced rollforming solutions that meet the specific needs of its customers. As the industry continues to evolve, [Company Name] is well-positioned to continue its success and be a trusted partner for companies looking to enhance their production capabilities.

High-Quality Street Light Pole Making Machine: A Complete Guide

Alberta, Canada - Street lighting plays a crucial role in urban and suburban areas, providing safety and visibility for pedestrians and motorists during the night. The manufacturing of street light poles requires precision, efficiency, and reliability to meet the growing demands for urban development. In response to this need, a leading manufacturing company has introduced a state-of-the-art street light pole making machine, which is set to revolutionize the production process.The new street light pole making machine, developed by [Company Name], is a significant advancement in the field of street lighting infrastructure. The machine is designed to streamline the manufacturing process, allowing for the efficient production of high-quality street light poles. With its advanced technology and innovative features, this machine has the potential to significantly impact the industry and contribute to the enhancement of urban infrastructure.[Company Name] is a renowned manufacturer of machinery and equipment for various industries, with a proven track record of providing cutting-edge solutions to meet the evolving needs of the market. The introduction of the street light pole making machine is a testament to the company's commitment to innovation and continuous improvement. By leveraging its expertise in engineering and manufacturing, [Company Name] aims to set a new standard in the production of street light poles and contribute to the development of sustainable and reliable urban infrastructure.The street light pole making machine is equipped with advanced technology and features that set it apart from conventional manufacturing equipment. It is designed to optimize the production process, from material handling and processing to finishing and quality control. The machine's high efficiency and precision enable the production of street light poles that meet the highest standards of quality and durability, ensuring their longevity and reliability in urban environments.One of the key highlights of the street light pole making machine is its versatility and customizability. It is capable of producing a wide range of street light pole designs and specifications, allowing for flexibility in meeting various project requirements. Whether it is for urban streets, highways, parks, or industrial areas, the machine can accommodate different configurations and sizes to suit the specific needs of urban planners and developers.Moreover, the street light pole making machine is designed with sustainability in mind. It incorporates energy-efficient processes and materials, reducing waste and environmental impact. As cities and communities continue to prioritize sustainability and energy conservation, the introduction of this machine aligns with the global movement towards more sustainable urban development.In addition to its technical capabilities, the street light pole making machine is supported by [Company Name]'s comprehensive customer service and technical support. The company's team of experts provides training, installation, and ongoing maintenance services to ensure the seamless integration and operation of the machine. This commitment to customer satisfaction and support further strengthens the value proposition of the machine for manufacturers and urban development stakeholders.The introduction of the street light pole making machine marks a significant milestone in the advancement of urban infrastructure manufacturing. With its cutting-edge technology, efficiency, and sustainability, the machine is poised to set new benchmarks for the production of street light poles. As [Company Name] continues to lead the way in innovation and engineering, the machine is expected to play a pivotal role in shaping the future of urban lighting and infrastructure worldwide.

High-Quality CZ Purlin Roll Forming Machine: Made in China

Are you in the construction industry and looking for a reliable and efficient way to manufacture CZ Purlins? Look no further, as HangZhou Roll Forming Machinery Co.,Ltd has the perfect solution for you - their advanced CZ Purlin Roll Forming Machine, which is making waves in the market. In this blog post, we will dive into the details of this remarkable product, exploring its features, benefits, and why it is a game-changer in the steel manufacturing industry.What is a CZ Purlin, you may ask? Well, it is a structural member found in roof trusses and walls to provide support and stability to a building. CZ Purlins are widely used in industrial and commercial construction due to their versatility and strength. With the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd, producing these components becomes a breeze.Now, let's take a closer look at this exceptional machine. Equipped with cutting-edge technology, the CZ Purlin Roll Forming Machine is designed to optimize efficiency and productivity. Its high-speed production capability can churn out CZ Purlins with incredible precision and accuracy, meeting the strictest industry standards. With this machine, you can say goodbye to manual labor-intensive processes and hello to automated precision manufacturing.One of the notable features of the CZ Purlin Roll Forming Machine is its versatility. It can handle various sizes and thicknesses of CZ Purlins, allowing you to cater to different construction needs. This flexibility is a huge advantage, as it eliminates the need to invest in multiple machines for different CZ Purlin specifications. With just one machine, you can produce a wide range of CZ Purlins, saving both space and resources.The CZ Purlin Roll Forming Machine boasts a user-friendly interface, making it accessible to operators of all skill levels. Its intuitive controls and adjustable parameters empower operators to customize output according to specific project requirements. Whether you need CZ Purlins for low-rise or high-rise buildings, this machine can adapt to meet your demands.Durability and reliability are crucial when it comes to machinery, and the CZ Purlin Roll Forming Machine does not disappoint. Built with top-quality materials, it can withstand heavy-duty usage and deliver consistent results over an extended period. This machine is engineered to endure the demands of high-volume production without compromising on its precision and performance.However, the advantages of the CZ Purlin Roll Forming Machine go beyond its features. Investing in this machine can yield significant benefits for your business. Firstly, it eliminates the need for outsourcing CZ Purlin production, saving you time and money. By bringing the manufacturing process in-house, you gain better control over your supply chain, ensuring uninterrupted production and timely delivery.Secondly, the CZ Purlin Roll Forming Machine enhances the overall quality of your CZ Purlins, which boosts customer satisfaction and improves your reputation. With precise dimensions, consistent results, and superior strength, your clients will have confidence in your product. This, in turn, leads to increased customer loyalty and repeat business.Moreover, the CZ Purlin Roll Forming Machine promotes sustainability. By being more energy-efficient and reducing material waste, it aligns with environmental regulations and supports your company's commitment to a greener future. Not only will you benefit from cost savings, but you will also contribute positively to the environment.In conclusion, the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd is a game-changer in the steel manufacturing industry. Its advanced technology, versatility, user-friendly interface, durability, and numerous benefits make it a must-have for any construction company. With this machine, you can streamline your production process, enhance your product quality, and position your business for growth and success. Say goodbye to manual labor and inefficiency, and embrace automation and precision with the CZ Purlin Roll Forming Machine.