High-Quality C/Z Purlin Roll Forming Machine for Sale - Complete Guide

By:Admin

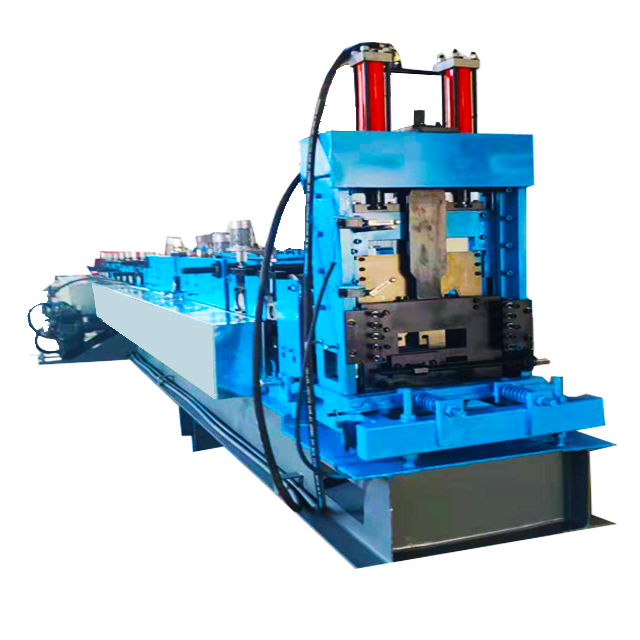

In recent years, there has been a significant shift in the construction industry towards more efficient and cost-effective building materials and methods. One of the key innovations that has emerged to meet this demand is the C/Z Purlin Roll Forming Machine. This machine is revolutionizing the way that steel purlins are manufactured, offering a faster, more accurate, and more cost-effective method for producing these essential building components.

The C/Z Purlin Roll Forming Machine, manufactured by {company name}, is designed to produce high-quality steel purlins with incredible speed and efficiency. The machine is capable of forming both C and Z shaped purlins, which are essential components in the construction of steel-framed buildings. These purlins are used to provide structural support and stability to the building, making them a critical component in the construction process.

The traditional method of manufacturing steel purlins involved cutting and punching individual pieces of steel, which was a time-consuming and labor-intensive process. However, the C/Z Purlin Roll Forming Machine has completely transformed this process. The machine uses a continuous rolling process to form the steel into the desired shape, eliminating the need for cutting and punching individual pieces. This not only speeds up the manufacturing process but also results in a more accurate and consistent product.

Additionally, the C/Z Purlin Roll Forming Machine is highly versatile, capable of producing purlins in a wide range of sizes and thicknesses. This makes it suitable for a variety of construction projects, from small-scale residential buildings to large industrial structures. The machine can also be easily adjusted to accommodate changes in production requirements, making it a highly adaptable and efficient tool for any construction project.

One of the key advantages of the C/Z Purlin Roll Forming Machine is its cost-effectiveness. By streamlining the manufacturing process and reducing the amount of labor required, the machine significantly lowers the production costs associated with steel purlins. This not only benefits the manufacturers but also makes steel-framed construction more affordable for builders and developers. As a result, the machine is helping to make steel-framed construction more accessible and attractive to a wider range of customers.

{Company name} has gained a strong reputation as a leading manufacturer of roll forming machines, with a commitment to innovation and quality. The company's C/Z Purlin Roll Forming Machine is a testament to their dedication to developing cutting-edge technology that meets the evolving needs of the construction industry. With a focus on precision engineering and high-quality components, {company name} has positioned itself as a trusted partner for construction companies looking to improve their manufacturing processes.

The C/Z Purlin Roll Forming Machine is not only revolutionizing the way steel purlins are manufactured but is also contributing to the overall advancement of the construction industry. By offering a more efficient, cost-effective, and versatile method for producing these essential building components, the machine is helping to drive innovation and progress in the field of construction.

In conclusion, the C/Z Purlin Roll Forming Machine is a game-changer for the construction industry. Its speed, efficiency, versatility, and cost-effectiveness are revolutionizing the way steel purlins are manufactured, making steel-framed construction more accessible and attractive to a wider range of customers. As a leading manufacturer of roll forming machines, {company name} is at the forefront of this transformation, with a commitment to delivering cutting-edge technology that meets the evolving needs of the construction industry. With the C/Z Purlin Roll Forming Machine, {company name} is not just shaping steel, it's shaping the future of construction.

Company News & Blog

High-Speed Corrugated Roll Forming Machine with Hydraulic Cutting - Ideal for 914mm and 1220mm Coil Width

Corrugated Sheet Forming Machine: A Revolutionary Solution for Modern BuildingBuilding construction is a vital industry that contributes significantly to the economy. Architects, builders, and property owners strive to create structures that are resilient and aesthetically appealing. However, the process requires heavy investment, and it's vital to use the best materials and tools. One crucial material is the corrugated sheet, which has become popular due to its durability, cost-effectiveness, and versatility. This is where the Corrugated Sheet Forming Machine comes in.The Corrugated Sheet Forming Machine is an innovative solution that has revolutionized the modern building industry. It is a machine designed to transform flat metal sheets into corrugated sheets, which are widely used for roofing, siding, and cladding applications. The machine uses a series of roller dies to create the corrugated profile, which can be customized to different shapes and sizes. It is a fast, efficient, and highly accurate way to produce high-quality corrugated sheets.One of the most important features of the Corrugated Sheet Forming Machine is its motorized cutting and fast drive system. This system allows for quick and easy processing of metal sheets, reducing the time and effort required to create corrugated sheets. Additionally, the hydraulic cutting system ensures precise cutting and minimal waste, further enhancing the machine's efficiency. The machine's 836 type, lengthened design, and 1220 mm coil width make it suitable for producing large volumes of sheets, making it ideal for commercial applications.The Corrugated Sheet Forming Machine is also highly customizable, allowing operators to create different corrugated profiles. This flexibility allows architects and builders to create unique designs that match their clients' preferences. The machine's versatility is further improved by its ability to process different metals, including galvanized steel, aluminum, and copper. This means that users can choose the material that best fits their project requirements, depending on factors such as durability, cost, and aesthetics.In conclusion, the Corrugated Sheet Forming Machine is an essential tool for the modern building industry. Its speed, accuracy, and versatility make it ideal for producing high-quality corrugated sheets for various applications. Whether you are constructing a commercial building, a residential house, or a metal structure, this machine can help you achieve your goals. If you are looking for a reliable and cost-effective way to produce corrugated sheets, the Corrugated Sheet Forming Machine is the perfect solution.

High-Quality New and Used Sheet Metal Machinery for the Industry

Title: Utilizing Sheet Metal Roll Forming for Efficient and Durable SolutionsIntroduction:In today's dynamic industrial landscape, the sheet metal industry plays a vital role in constructing sturdy and versatile products across various sectors. To ensure optimal results, it is crucial to have access to top-notch sheet metal machinery that guarantees precision, efficiency, and durability. In this blog, we will explore the advantages of sheet metal roll forming and shed light on its significance in creating high-quality products. Let's delve into the details!Understanding Sheet Metal Roll Forming:Sheet metal roll forming is a highly efficient process that involves bending and shaping metal sheets into desired profiles. This technique allows engineers and fabricators to create complex shapes and structures, such as panels, channels, tubes, and angles. By passing a continuous strip of metal through a series of rollers, roll forming ensures consistent dimensions throughout the entire length of the product, providing exceptional accuracy and uniformity.Benefits of Sheet Metal Roll Forming:1. Cost-Effective Production:One of the significant advantages of sheet metal roll forming is its cost-effectiveness. This process eliminates the need for multiple components, such as fasteners, welds, and adhesives. By shaping the metal into the desired form without additional attachments, roll forming minimizes production costs, reducing labor and material requirements.2. Enhanced Efficiency and Speed:Sheet metal roll forming provides a highly efficient and rapid production method. It enables continuous production without the need for frequent stops and starts. The machinery used in roll forming operates at high speeds, allowing for large volumes of products to be manufactured swiftly. This aspect is particularly beneficial for industries that require high production rates, meeting tight deadlines, and satisfying customer demands promptly.3. Durability and Structural Integrity:By utilizing sheet metal roll forming techniques, manufacturers can create products with exceptional strength and durability. The continuous bending process enhances the structural integrity of the metal, resulting in robust and long-lasting components. The consistency achieved through roll forming ensures that all parts produced possess identical specifications, eliminating variations that could compromise their durability.4. Versatility and Customizability:Sheet metal roll forming offers extensive possibilities for customization, allowing engineers to create a wide range of profiles and designs. With the ability to accommodate various metals, thicknesses, and widths, roll formers enable the production of intricate shapes with precise tolerances. This versatility makes roll forming suitable for diverse applications in industries such as automotive, construction, furniture, aerospace, and more.Keyword Placement:Now let's discuss the importance of incorporating relevant keywords within the blog to improve its search engine optimization (SEO). Keywords related to "Sheet Metal Roll Forming" should be strategically placed throughout the content, including in headings, subheadings, and body paragraphs. Additionally, ensure the keywords are naturally integrated within the text to maintain readability and avoid keyword stuffing.Conclusion:Sheet metal roll forming revolutionizes the manufacturing process by offering cost-effective production, enhanced efficiency, durability, and customization. By harnessing high-quality roll forming machinery, such as those provided by Benoit Sheet Metal Equipment, Inc., fabricators can create products that meet the highest standards of quality and precision. Whether you belong to the automotive, construction, or any other industry that relies on sheet metal, incorporating roll forming techniques can significantly elevate your manufacturing capabilities. Embrace the power of sheet metal roll forming and unlock a world of possibilities for your business!

New Steel Product Quickly Gains Popularity in Construction Industry

[Company Name] Launches Robust Purlins to Support Construction Industry[date][Location] [Company Name], a leading manufacturer and supplier of construction materials, has announced the release of their latest innovation in the building industry – robust purlins. These high-quality steel components are set to revolutionize the way construction projects are carried out, offering increased durability, ease of installation, and cost-effectiveness.Purlins, commonly used in roofing and cladding systems, play a crucial role in providing structural support to buildings. They are horizontal, load-bearing beams that span between trusses or rafters and help transfer the weight of the roof to the main support structure. With [Company Name]'s new range of robust purlins, builders and contractors can now have peace of mind knowing that they are using a dependable and long-lasting product.The concept behind [Company Name]'s robust purlins lies in their meticulous design and precise engineering. Crafted from high-strength galvanized steel, these purlins offer exceptional structural integrity, ensuring stability and longevity of the buildings they are used in. The galvanization process protects against corrosion and adds an extra layer of resilience, making the purlins suitable for a variety of environmental conditions.Installing the new purlins is a breeze, thanks to their innovative design. Their lightweight nature allows for easy handling, reducing the time and effort required during the construction process. The purlins have also been designed to fit seamlessly with existing building components, making them adaptable for both new constructions and renovation projects.One of the standout features of [Company Name]'s robust purlins is their cost-effectiveness. By using these high-quality purlins, builders can reduce the need for additional support structures and minimize material wastage. The purlins' strength-to-weight ratio ensures they can withstand heavy loads, reducing the number of purlins required, ultimately saving on project costs.In line with [Company Name]'s commitment to sustainable practices, the new purlins are made from recycled materials. By utilizing these eco-friendly purlins, builders and designers can contribute to reducing their carbon footprint, promoting a greener, more sustainable construction industry."We are extremely excited to introduce our new range of robust purlins to the market," says [Company Name]'s CEO, [CEO Name]. "With their impressive strength, ease of installation, and cost-effectiveness, we believe these purlins will make construction projects more efficient while providing durable support structures."As a company dedicated to customer satisfaction, [Company Name] aims to provide exceptional after-sales assistance and technical support. With a team of experienced engineers on standby, customers can expect seamless integration of the purlins into their building projects, along with any necessary guidance or troubleshooting.[Company Name]'s robust purlins are now available for purchase and can be ordered through their website or authorized distributors. The company also plans to conduct workshops and training sessions to educate builders and contractors on the benefits and proper installation of these purlins.In conclusion, [Company Name]'s launch of their robust purlins marks a significant milestone in the construction industry. With enhanced durability, ease of installation, and cost-effectiveness, these purlins are set to become the go-to choice for builders and contractors worldwide. By incorporating these innovative components into their projects, construction professionals can expect increased efficiency, reduced costs, and durable structures that stand the test of time.

High-Quality Roofing Sheet Roll Forming Machines for Efficient Sheet Rolls Forming Process

Roofing Sheet Roll Forming Machine: Revolutionizing the Roofing Industry[City], [Date] - [Company Name], a leading manufacturer of roll forming machines, is proud to introduce their latest innovation in the roofing industry - the Roofing Sheet Roll Forming Machine. This groundbreaking machine is set to revolutionize the way roofing sheets are manufactured, offering enhanced efficiency and superior quality products.The Roofing Sheet Roll Forming Machine is a state-of-the-art piece of equipment designed to produce roofing sheets with precision and speed. By utilizing advanced roll forming technology, this machine is capable of shaping metal sheets into a variety of profiles and dimensions, perfectly suited for roofing applications. With its efficient and automated production process, the machine is capable of meeting the demands of both small-scale roofing projects and large commercial operations.One of the key features of the Roofing Sheet Roll Forming Machine is its versatility. It can produce a wide range of roofing sheet profiles, including corrugated, trapezoidal, and standing seam designs. This flexibility allows roofing contractors and manufacturers to meet the diverse requirements of their customers, offering them a wide selection of roofing options.The machine's high-speed production capabilities make it an ideal choice for large-scale operations. With its precise and reliable roll forming process, the Roofing Sheet Roll Forming Machine can produce roofing sheets at an impressive rate, significantly reducing production time and costs. This increased productivity translates into higher profitability for roofing companies, allowing them to take on more projects and meet tight deadlines.Quality is of utmost importance in the roofing industry, and the Roofing Sheet Roll Forming Machine delivers exceptional results. By using top-quality materials and advanced manufacturing techniques, this machine ensures that every roofing sheet produced meets the highest quality standards. The machine's precision-engineered rollers and cutting blades contribute to the accurate shaping of the metal sheets, creating well-formed and dimensionally accurate roofing products.Additionally, the Roofing Sheet Roll Forming Machine offers excellent durability and reliability. Manufactured with robust components and built to withstand heavy-duty use, this machine can operate consistently even in demanding production environments. Its user-friendly design and intuitive controls make it easy to operate, requiring minimal maintenance and reducing downtime.By investing in the Roofing Sheet Roll Forming Machine, companies can streamline their production process and substantially improve their overall efficiency. With its superior speed, versatility, and quality output, this machine is set to become an indispensable asset in the roofing industry.[Company Name] is dedicated to providing exceptional after-sales service and technical support. With their extensive experience in roll forming machine manufacturing, they are committed to assisting customers in optimizing their production processes and ensuring the long-term performance of their machines.About [Company Name]:[Company Name] is a renowned manufacturer of roll forming machines, specializing in Roofing Sheet Roll Forming Machine, CZ Purlin Machine, and Light Steel Framing products. With a focus on delivering innovative and reliable solutions, they have become a trusted name in the industry. Their commitment to superior quality, advanced technology, and excellent customer service has earned them a reputation as a leading manufacturer in China. For more information, please visit [Company Website].For media inquiries:[Company Name][Contact Person][Phone Number][Email Address]

Roll Forming Machine Manufacturers For Sale in China - Superior Quality

Roll Forming Machine Manufacturers in China are Dedicated to Providing High-Quality MachinesIn today's world, the demand for roll forming machines has drastically increased. Roll forming machines are used by manufacturers in diverse industries to create uniform shapes of metal sheets. These machines are highly efficient and produce high-quality products in a short time. There are many roll forming machine manufacturers in China, and RISHBIN is committed to providing customers with the best quality roll forming machines.Founded in 1998, RISHBIN is a sheet metal roll forming machine manufacturer that offers a comprehensive range of roll forming machines for different applications. Over the years, the company has built a reputation for producing high-quality machines that are reliable, efficient, and durable. RISHBIN roll forming machines are used in the construction, automobile, HVAC, and packaging industries.The company prides itself on providing customized solutions to meet the specific needs of their customers. This is possible because RISHBIN has a team of experienced engineers who develop unique designs for their customers. The engineers use modern software to design and simulate the machines before production to ensure that the final product meets the customer's specifications.RISHBIN roll forming machines are designed to be highly efficient in terms of speed and accuracy. The machines are manufactured using the latest technology and high-quality materials to ensure they last longer and require minimal maintenance. The company uses top-quality components such as Mitsubishi, Siemens, and Schneider for the electrical parts, and SKF, NSK, and Timken for the bearings to ensure the machines' high stability and reliability.The company's roll forming machines are available in different models, including simple manual machines, hydraulic machines, and fully automated roll forming machines. This range of machinery allows customers to choose a product that suits their production needs and budget.RISHBIN is also committed to providing excellent customer service. The company has a team of trained and experienced customer service representatives who are available 24/7 to provide support and answer customer questions. This ensures that customers can have peace of mind knowing that they will receive prompt and efficient after-sales service.In conclusion, RISHBIN is committed to providing customers with the best quality roll forming machines. The company's commitment to quality, efficiency, and customer service has earned it a reputation as one of the leading roll forming machine manufacturers in China. By working with RISHBIN, customers can be assured of getting customized products that meet their specific requirements and budgets.

Discover the Efficiency and Precision of a State-of-the-Art Roofing Iron Moulding Machine

Roofing Iron Moulding Machine Revolutionizes the Construction IndustryInnovations in machinery have always played a pivotal role in shaping the construction industry, revolutionizing the way buildings are designed, constructed, and maintained. One such remarkable invention is the Roofing Iron Moulding Machine, a cutting-edge piece of equipment that has been making waves in the industry due to its efficiency and effectiveness in producing high-quality roofing iron.Developed by a leading construction machinery manufacturer, this groundbreaking machine has garnered widespread attention from contractors, builders, and architects alike. With its state-of-the-art technology and impressive features, it has quickly become an indispensable tool for those involved in roofing projects of all scales.The Roofing Iron Moulding Machine is capable of producing impeccable roofing iron sheets with utmost precision and consistency. It employs advanced molding techniques that ensure each sheet is perfectly shaped, allowing for seamless installation and optimal performance. The machine's ability to produce a large volume of roofing iron in a short span of time has significantly boosted productivity, reducing construction time and costs.One of the key features that sets this machine apart is its versatility. It is capable of producing roofing iron sheets of various profiles, sizes, and thicknesses, catering to the diverse needs and preferences of builders and homeowners. Whether it's a traditional corrugated profile or a contemporary standing seam design, the Roofing Iron Moulding Machine can deliver the desired results with impeccable accuracy.Furthermore, this cutting-edge machine offers unmatched customization options. It allows users to create roofing iron sheets with unique colors, textures, and patterns, enabling builders to add a touch of individuality and creativity to their projects. This feature has become particularly popular among architects and designers who strive to produce aesthetically pleasing structures that stand out in the urban landscape.Apart from its exceptional performance capabilities, the Roofing Iron Moulding Machine is also known for its user-friendly interface and intuitive controls. Its automated operations mitigate the chances of human errors and ensure a smooth production process. Additionally, the machine's low energy consumption and environmentally friendly design make it a sustainable choice for the construction industry.The utilization of the Roofing Iron Moulding Machine has had a significant impact on the construction industry worldwide. By streamlining the production process and enhancing efficiency, it has allowed contractors and builders to execute projects in a more cost-effective and timely manner. Furthermore, the availability of high-quality roofing iron sheets has contributed to the durability and longevity of buildings, reducing maintenance needs and costs in the long run.The introduction of this innovative machine has revolutionized the roofing sector, providing a valuable solution that addresses the industry's challenges and demands. Its ability to produce roofing iron sheets that meet stringent quality standards has earned it a reputation as the go-to choice for builders seeking durable and reliable materials.As the construction industry continues to evolve, the Roofing Iron Moulding Machine will undoubtedly play an instrumental role in shaping the future of roofing technology. With its unparalleled precision, efficiency, and versatility, it is poised to become an industry standard, setting new benchmarks for quality and innovation.In conclusion, the Roofing Iron Moulding Machine is an extraordinary invention that has transformed the construction industry. Its state-of-the-art technology, user-friendly interface, and ability to produce high-quality roofing iron sheets with precision and efficiency have made it an indispensable tool for contractors and builders alike. As this remarkable machine continues to make waves in the industry, it promises to redefine the way roofs are designed and constructed for years to come.

Exploring the Benefits of Horizontal Corrugated Roof Panels for Your Project

Horizontal Corrugated Roof Panel Seeks to Offer Durable, Energy-Efficient Roofing Solutions for Commercial and Residential BuildingsThe roofing of any building is one of its most important components as it protects the structure from the elements and keeps the occupants safe and comfortable. Therefore, it is essential to have a reliable, durable, and energy-efficient roofing system to ensure long-term protection, and to enhance the building’s overall functionality and aesthetics.One company that has been at the forefront of providing innovative roofing solutions is Horizontal Corrugated Roof Panel, a leading manufacturer and distributor of metal roofing systems for commercial and residential buildings. Based in the United States, Horizontal Corrugated Roof Panel has built a reputation for excellence in the roofing industry, and its products are widely used in various types of buildings, including industrial warehouses, retail outlets, commercial offices, and residential homes.Horizontal Corrugated Roof Panel manufactures a wide range of metal roofing solutions that are designed to meet the needs of different clients. The company’s product portfolio includes standing seam panels, corrugated panels, snap-lock panels, and curved panels, among others. These products come in various sizes, gauges, and colors, allowing customers to choose the ideal roofing system for their specific needs. Furthermore, both pre-painted and unpainted finishes are available, as well as a full line of accessories that are necessary for installation.One of the most notable aspects of Horizontal Corrugated Roof Panel’s products is that they are made from top-quality materials, which ensure durability, longevity, and energy efficiency. The roofing panels are manufactured from Galvalume® steel, a corrosion-resistant alloy that is coated with a layer of aluminum and zinc. This ensures that the panels can withstand harsh weather conditions, including rain, snow, and wind, without getting eroded or corroded.In addition to its exceptional durability, Horizontal Corrugated Roof Panel’s products are also energy-efficient, which makes them a popular choice amongst environmentally-conscious consumers. The roofing panels are designed to reflect solar heat, which reduces the amount of energy needed to cool the building’s interior, and ultimately contributes to lower energy bills. This feature is particularly beneficial in hot climates, where air conditioning costs can be a significant burden.Another distinctive feature of Horizontal Corrugated Roof Panel’s products is their ease of installation. The company’s roofing panels come with detailed installation instructions, which ensure that the panels are installed correctly and safely. Additionally, the roofing panels are lightweight, which means that they can be easily transported, handled, and installed. This reduces the overall installation time and costs, allowing customers to enjoy their new roofing system in minimal time.As a pioneer in the roofing industry, Horizontal Corrugated Roof Panel has always placed great emphasis on providing top-notch customer service. The company’s dedicated staff is committed to providing clients with expert advice and guidance, ensuring that they make informed decisions when purchasing their roofing systems. Furthermore, the company offers a comprehensive warranty on its products, which gives customers peace of mind and protection against any unforeseen issues that may occur.In conclusion, Horizontal Corrugated Roof Panel’s products are an excellent choice for anyone who requires a durable, energy-efficient, and easy-to-install roofing system for their commercial or residential building. With a wide range of products available, exceptional quality, and outstanding customer service, the company has established itself as a trusted name in the roofing industry.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

New Aluminum Profile Polishing Machine Unveiled to Enhance Finishing Quality

Aluminum Profile Polishing Machine: The Future of Aluminum FinishingIn recent years, aluminum has become one of the most commonly used materials in various industries. This versatile metal has excellent properties that make it useful in diverse applications, such as construction, transportation, electronics, and aerospace. However, achieving a high-quality finish on aluminum surfaces can be challenging, especially for manufacturers who need to meet strict customer demands and industry standards. That's why the Aluminum Profile Polishing Machine (APP) has emerged as a game-changer in aluminum finishing processes.APP is a state-of-the-art machine that uses advanced technology to polish and buff aluminum profiles with precision, speed, and consistency. The machine's design and functionality are tailored to meet the specific needs of the aluminum industry, where the demand for high-performance products and cost-effective solutions is high.One of the key benefits of APP is that it can handle a wide range of aluminum profiles, from simple shapes to complex geometries, such as extrusions, tubes, angles, and channels. Thanks to its modular and versatile setup, the machine can be adapted to different production requirements, ensuring maximum efficiency and productivity.Another advantage of APP is its excellent polishing performance, which results in a mirror-like finish on aluminum surfaces. With the help of state-of-the-art abrasives and polishing agents, APP can remove scratches, corrosion, and any other surface imperfections, leaving a smooth and shiny surface that meets the most demanding quality standards.Moreover, APP is easy to operate and maintain, thanks to its user-friendly interface and robust construction. The machine can be controlled through a touch screen, which allows operators to adjust polishing parameters, such as speed, pressure, and angle, in real-time. Additionally, APP's modular design allows for easy access and cleaning of its components, reducing downtime and minimizing maintenance costs.The Aluminum Profile Polishing Machine is also environmentally friendly, as it uses water-based polishing agents that are free of harmful chemicals and VOCs. This makes APP a sustainable solution that meets the growing demand for eco-friendly manufacturing practices and regulations.APP is a product of [Omitted for Privacy], a leading manufacturer of aluminum processing machinery. With over [Omitted for Privacy] years of experience, the company has become a trusted partner of many aluminum companies worldwide, providing them with innovative and reliable solutions that improve their efficiency and profitability.According to [Omitted for Privacy], the Aluminum Profile Polishing Machine is the result of extensive research and development, aiming to address the growing challenges in the aluminum finishing industry. The company's team of experts has worked hard to ensure that APP meets the highest quality standards and customer expectations."[Omitted for Privacy] is committed to delivering cutting-edge technology that enables our customers to stay ahead in the market. We believe that the Aluminum Profile Polishing Machine is a game-changer in the aluminum finishing industry, as it offers unparalleled performance, versatility, and sustainability," said [Omitted for Privacy], CEO of [Omitted for Privacy].In conclusion, the Aluminum Profile Polishing Machine is a revolutionary solution that unlocks new possibilities for aluminum manufacturers. With its advanced technology, exceptional performance, and user-friendly design, APP can help companies achieve faster and more reliable results, while reducing costs and improving sustainability. As the demand for high-quality aluminum products continues to increase, APP is poised to become the future of aluminum finishing.

Steel Edging Machine: Achieve the Perfect Finish for Your Steel Coils

: A Guide to Choosing the Right Steel Edge FinisherSteel edge conditioning is an important and necessary process for anyone working with steel coils. It involves rolling the edge of the coil to a specific shape, ensuring that it is safe for any exposed applications. This process not only enhances the appearance of the finished product but also ensures that the edge is safe to handle and does not pose a risk to anyone during use.One of the essential tools for edge conditioning is a Rolled Coil Steel Edging Machine. This machine is designed to produce high-quality edges that are free of sharp edges and burrs. It can be used for a wide range of applications, including industrial processing, automotive manufacturing, and construction.Choosing Your Edge Finish SWhen looking for a Rolled Coil Steel Edging Machine, it is essential to select one that meets your specific needs. There are different types of edge finishers, and each one has its advantages and disadvantages.Popular edge finishes include rounded edges, beveled edges, and deburred edges.Rounded EdgesThere are different types of rounded edges, including full-round, half-round, and quarter-round. When choosing a rounded edge, you need to consider the material thickness, the coil width, and the edge radius. The machine should be capable of producing the desired radius within a specific tolerance range.Beveled EdgesBeveled edges are inclined edges that angle down from the edge of the steel coil. They improve the appearance of the finished product and provide additional strength and durability. Beveled edges can be used in industrial applications, automotive manufacturing, and construction.Deburred EdgesA deburred edge is one that is free of any sharp edges or burrs. This type of edge is essential for any application where the edge of the steel coil will be exposed. It is also critical when handling the material, as sharp edges can cause injury to the worker.Metal Coil Slitting MachineIn addition to the Rolled Coil Steel Edging Machine, a Metal Coil Slitting Machine is another essential tool for working with steel coils. It is used to cut large coils of steel into smaller, more manageable sizes. This machine saves time and labor costs, making it an essential tool for any industrial operation.When choosing a Metal Coil Slitting Machine, you need to consider the material thickness and gauge, the number of cutting blades, and the feed speed. It should also be easy to operate, with minimal maintenance requirements.SummaryEdge conditioning is an important process for anyone working with steel coils. Rolled Coil Steel Edging Machines are essential tools for producing high-quality edges that are safe and free of sharp edges and burrs. When choosing an edge finish, you need to consider your specific needs and the type of application you are working on.In addition to an edging machine, a Metal Coil Slitting Machine is also essential for cutting large coils into smaller, more manageable sizes. When choosing a Metal Coil Slitting Machine, it is essential to consider the material thickness and gauge, the number of cutting blades, and the feed speed.In conclusion, investing in the right equipment for edge conditioning and coil slitting will increase efficiency, enhance productivity, and improve the quality of the finished product, leading to client satisfaction and business growth.